Method for flow-electrode capacitive deionization (FCDI)-based desalination and application

A technology of capacitive deionization and flow electrodes, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of lack of optimization of process parameters, etc., and achieve the effects of simple structure of the reaction device, saving of preparation costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

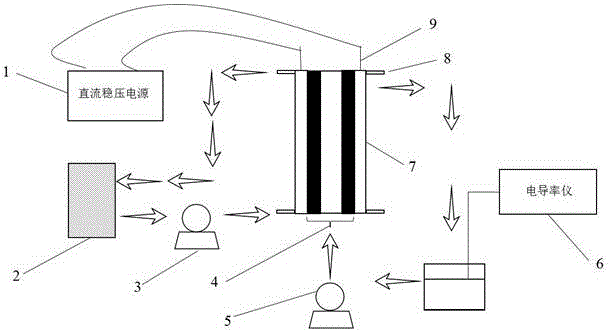

[0055] The above-mentioned FCDI system was used to treat saline wastewater with an initial NaCl concentration of 500mg / L.

[0056] The operating conditions are: the flow rate of the mobile electrode is 100ml / min, the flow rate of the water inlet is 15ml / min, the operating voltage is 2.0V, the distance between the electrode plates is 2mm, and the initial concentration is 500mg / L.

[0057] Follow the steps below:

[0058] (1) Use deionized water (conductivity less than 5 μs / cm) to prepare a salt solution with a NaCl concentration of 500 mg / L, that is, simulated raw water.

[0059] (2) Using the method of circulating water in and out, use a constant current peristaltic pump to pump out 500mg / L NaCl raw water at a certain flow rate, pump it in from the bottom of the FCDI module unit, flow out through the top, and finally flow back into the beaker, using direct current The regulated power supply applies a certain power supply voltage to both ends of the FCDI module unit, and charg...

Embodiment 2

[0066] The above-mentioned FCDI system was used to treat saline wastewater with an initial NaCl concentration of 1000mg / L.

[0067] The operating conditions are: the flow rate of the mobile electrode is 100ml / min, the flow rate of the water inlet is 15ml / min, the operating voltage is 2.0V, the distance between the electrode plates is 2mm, and the initial concentration is 1000mg / L.

[0068] Follow the steps below:

[0069] (1) Use deionized water (conductivity less than 5 μs / cm) to prepare a salt solution with a NaCl concentration of 1000 mg / L, that is, simulated raw water.

[0070] (2) Using the method of circulating water in and out, use a constant current peristaltic pump to pump out 1000mg / L NaCl raw water at a certain flow rate, pump it in from the bottom of the FCDI module unit, flow out through the top, and finally flow back into the beaker, using direct current The regulated power supply applies a certain power supply voltage to both ends of the FCDI module unit, and cha...

Embodiment 3

[0077] The above-mentioned FCDI system was used to treat saline wastewater with an initial NaCl concentration of 2000mg / L.

[0078] The operating conditions are: the flow rate of the mobile electrode is 100ml / min, the flow rate of the water inlet is 15ml / min, the operating voltage is 2.0V, the distance between the electrode plates is 2mm, and the initial concentration is 2000mg / L.

[0079] Follow the steps below:

[0080] (1) Use deionized water (conductivity less than 5 μs / cm) to prepare a salt solution with a NaCl concentration of 2000 mg / L, that is, simulated raw water.

[0081] (2) Using the method of circulating water in and out, use a constant current peristaltic pump to pump out 2000mg / L NaCl raw water at a certain flow rate, pump it in from the bottom of the FCDI module unit, flow out through the top, and finally flow back into the beaker, using direct current The regulated power supply applies a certain power supply voltage to both ends of the FCDI module unit, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com