Method for preparing high-purity chromate by utilizing ferrochrome

A technology of pure chromate and ferrochromium, applied in the direction of cells, electrolytic components, electrolytic process, etc., to achieve the effect of simplifying process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

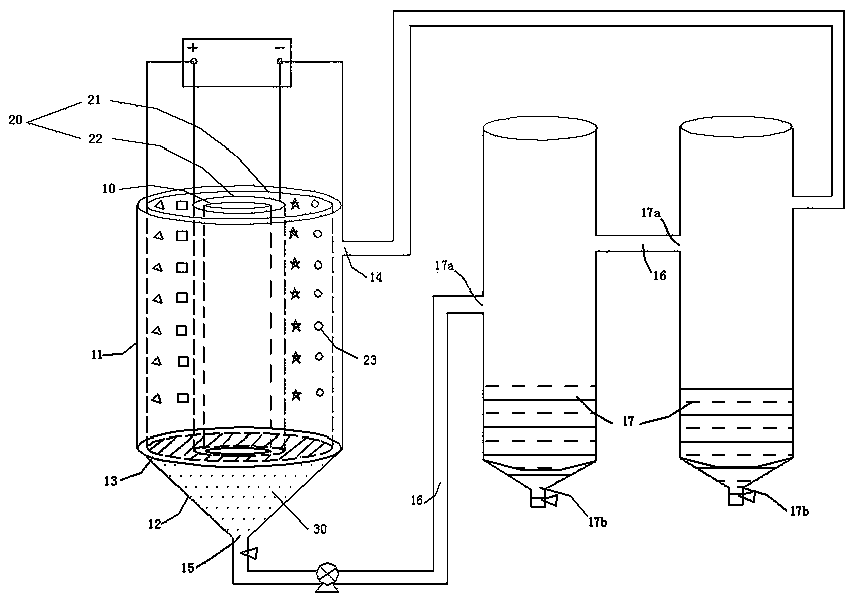

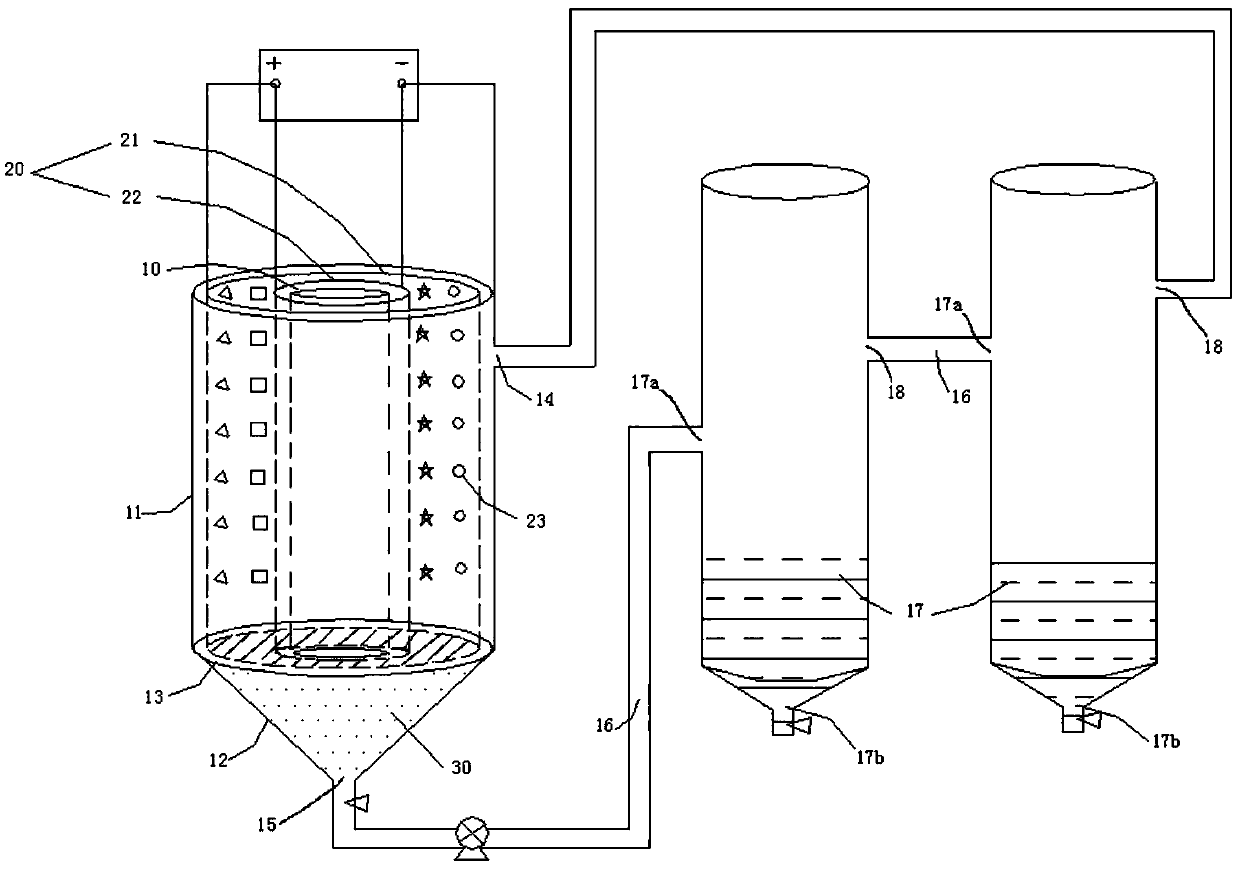

[0085] Preparation of high-concentration sodium chromate solution: a titanium mesh with an outer diameter of 280 mm and an inner diameter of 80 mm, and a stainless steel mesh with an outer diameter of 70 mm were inserted into a stainless steel hollow cylinder with an inner diameter of 300 mm. Hollow plastic partitions are used to insulate the titanium mesh and stainless steel. An electrolysis device with double anode and double cathode is formed. Fill the titanium mesh with 100 kg of ferrochrome with a particle size of <100 mm, and fill the electrolytic cell with 44 L of sodium hydroxide solution with a concentration of 260 g / L. The titanium mesh of the electrolytic cell is electrically connected with the positive pole of the power supply, and the stainless steel is electrically connected with the negative pole of the power supply. Turn on the power supply, adjust the output current to 100 A, and the cell voltage < 2.42 V. After 610 h of continuous electrolysis reaction, the ...

Embodiment 1

[0088] Take 500 mL of a high-concentration sodium chromate solution with a sodium chromate concentration of 530 g / L and a carbon content of 5 g / L and put it into the hydrothermal reaction kettle, set the reaction temperature at 280 °C, the reaction time for 12 h, and the reaction pressure at 8 MPa. After the reaction was finished, a solid-liquid mixed slurry was obtained, and the slurry was filtered and separated to obtain 29 g of chromium hydroxide in the solid phase and 470 mL of sodium chromate solution in the liquid phase. The liquid phase was concentrated by evaporation to obtain a sodium chromate product with a purity of 99.1%.

Embodiment 2

[0090] Take 500 mL of a high-concentration sodium chromate solution with a sodium chromate concentration of 260 g / L and a carbon content of 2.5 g / L and pass it into the hydrothermal reaction kettle. Set the reaction temperature to 220 °C, the reaction time to 2 h, and the reaction pressure to 3 MPa. After the reaction was finished, a solid-liquid mixed slurry was obtained, and the slurry was filtered and separated to obtain 14 g of chromium hydroxide in the solid phase and 480 mL of sodium chromate solution in the liquid phase. The liquid phase is concentrated by evaporation to obtain a sodium chromate product with a purity of 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com