Patents

Literature

30results about How to "Increase the electrolysis area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamed copper-silver alloy material and its preparation method

InactiveCN102443823AIncrease the electrolysis areaReduce use costElectroforming processesSilver electrodeAlloy

The invention discloses a foamed copper-silver alloy material and its preparation method. With a three-dimensional net structure, the copper-silver alloy material is composed of a copper-silver alloy, wherein, the metal copper accounts for 80%-99.5% of the total mass of the alloy material, and silver accounts for 0.5%-20%. The preparation method comprises: electrodepositing the copper-silver alloy on conductive foam cotton, and finally carrying out high-temperature vacuum heat treatment. The alloy material of the invention has substantially reduced consumption of precious metal silver, simple production process, and low production cost, so that it can substitute copper-silver electrodes used in sewage treatment.

Owner:周宏霞

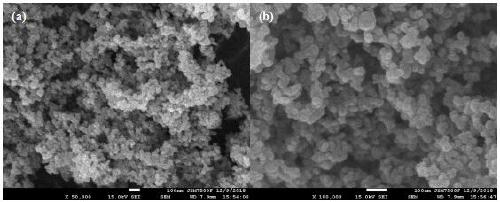

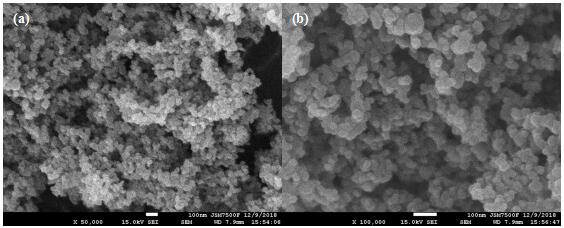

Cerium-doped iron hydroxide modifying foam titanium material and preparing method and application thereof in water treatment

ActiveCN109261140AIncrease precipitation speedGood application effectWater treatment parameter controlOther chemical processesPorosityControllability

The invention discloses a cerium-doped iron hydroxide modifying foam titanium material and a preparing method thereof. A three-electrode system is formed with a foam titanium plate serving as a working electrode, a platinum sheet serving as a counter electrode and a saturated calomel electrode serving as a reference electrode. An aqueous solution containing ferric chloride, cerium chloride, sodiumsulfate, polyvinylpyrrolidone and hydrogen peroxide serves as an electrolyte solution, cyclic voltammetry is adopted for cyclic circle sweeping, and then a working electrode is taken out, washed anddried to obtain the cerium-doped iron hydroxide modifying foam titanium material. The invention further discloses application of the cerium-doped iron hydroxide modifying foam titanium material in water treatment. According to the cerium-doped iron hydroxide modifying foam titanium material and the preparing method and application thereof, porous foam titanium serves as a matrix, cerium-doped ironhydroxide modifies the surface, and the applicability and activity of iron hydroxide are improved; the cerium-doped iron hydroxide modifying foam titanium material has high porosity and adsorption and oxidation capacity, can serve as adsorbing filler, filter elements or electrodes to be applied to water treatment, secondary pollution to the treated water cannot be caused, and the preparing process has high controllability and stability.

Owner:SHENGSHI LANDSCAPE GRP CO LTD

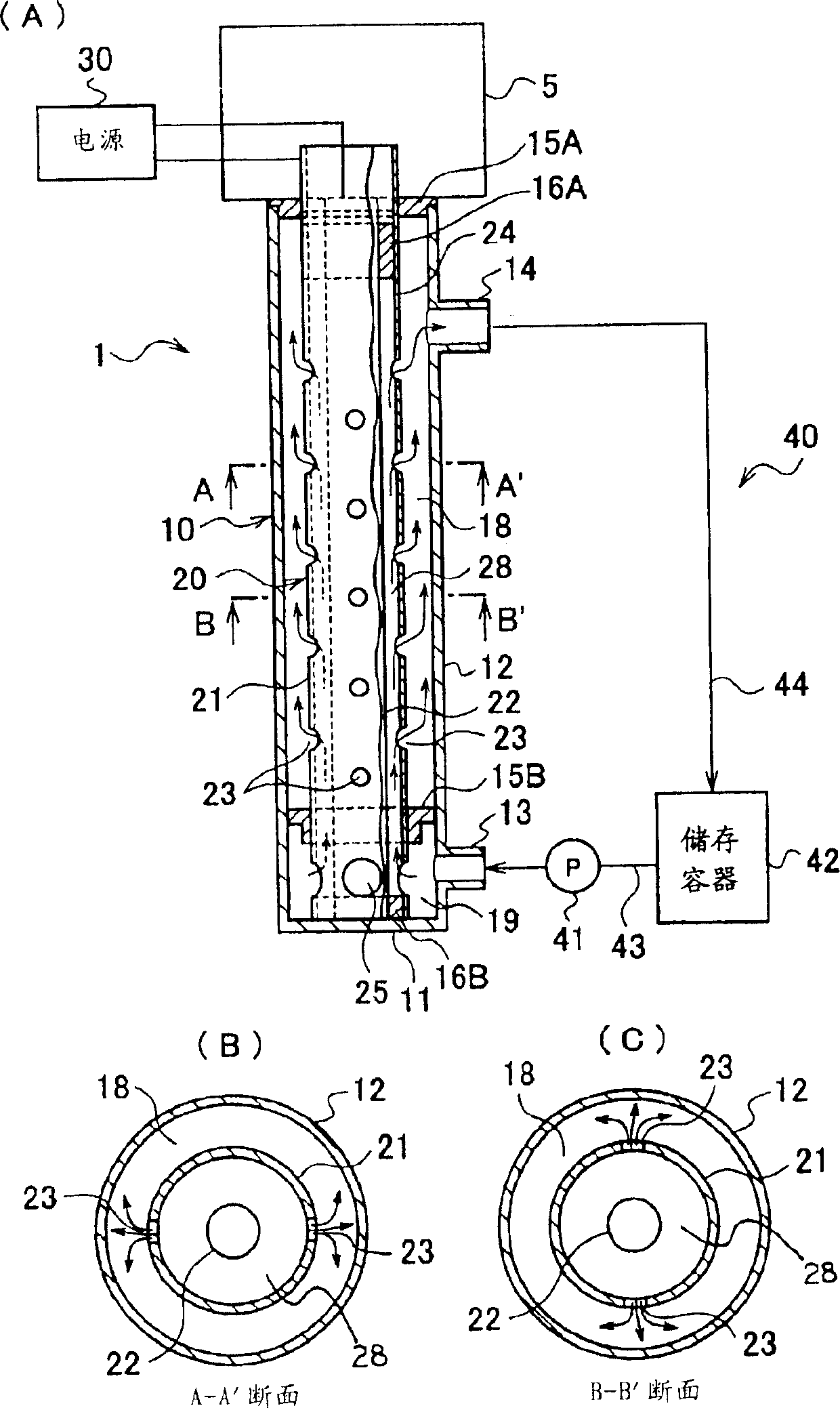

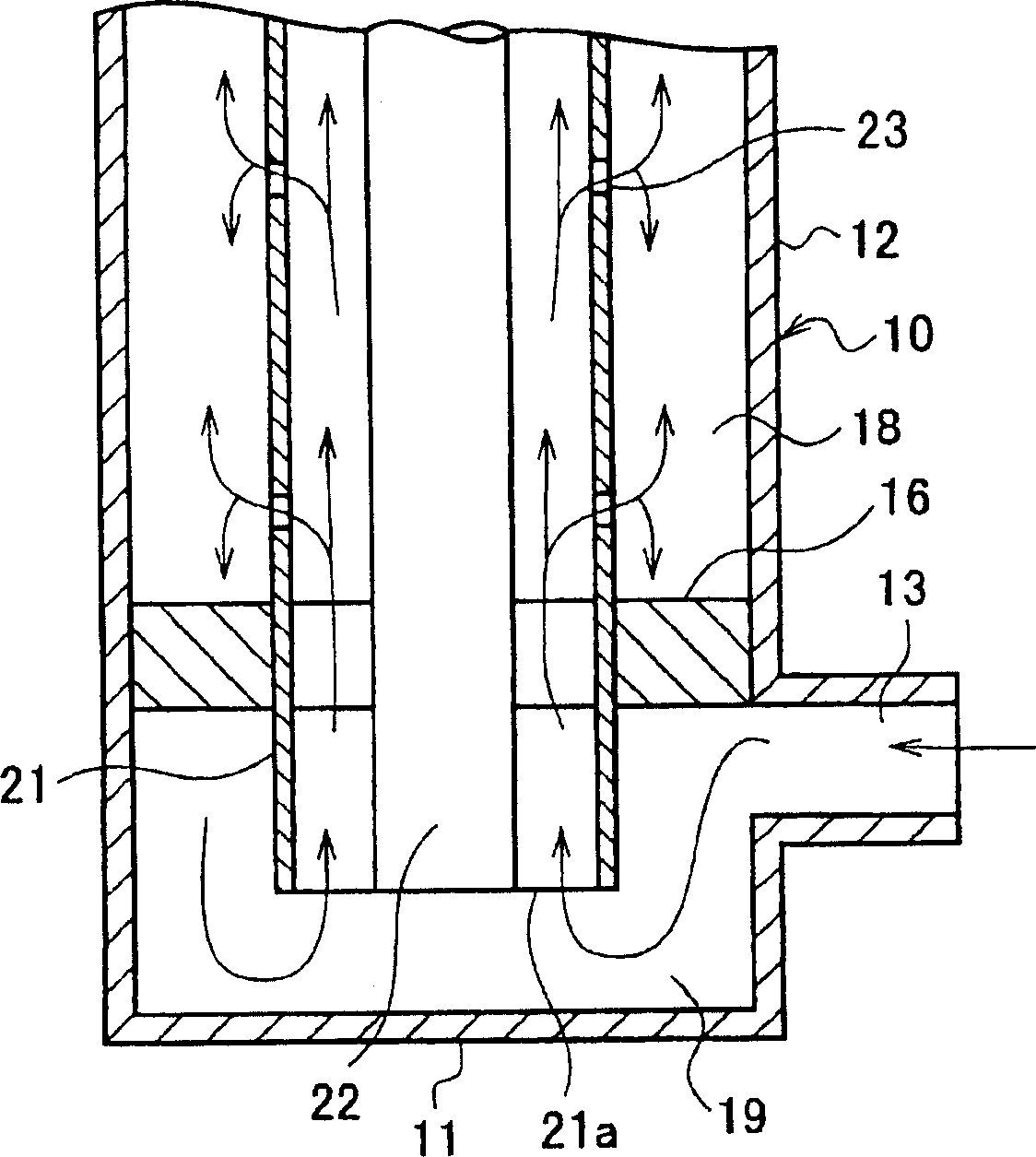

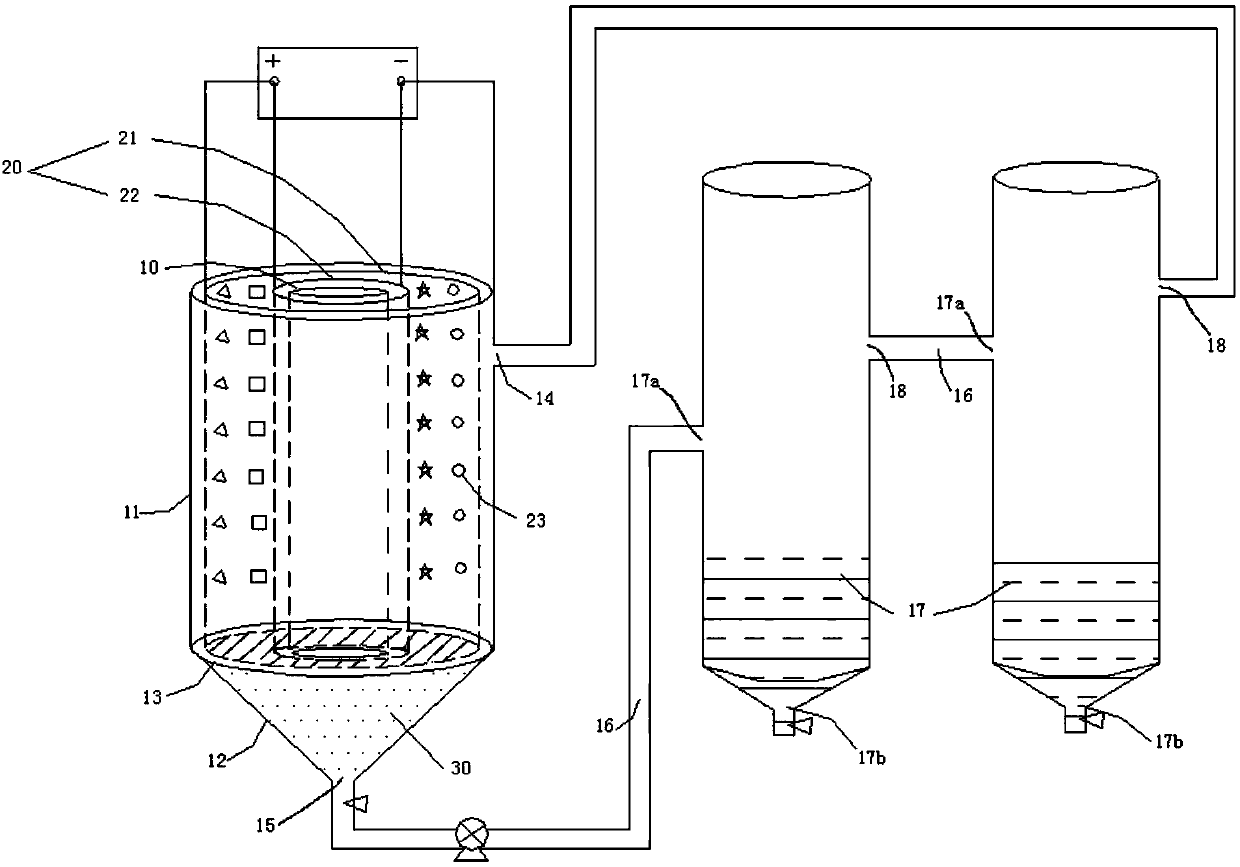

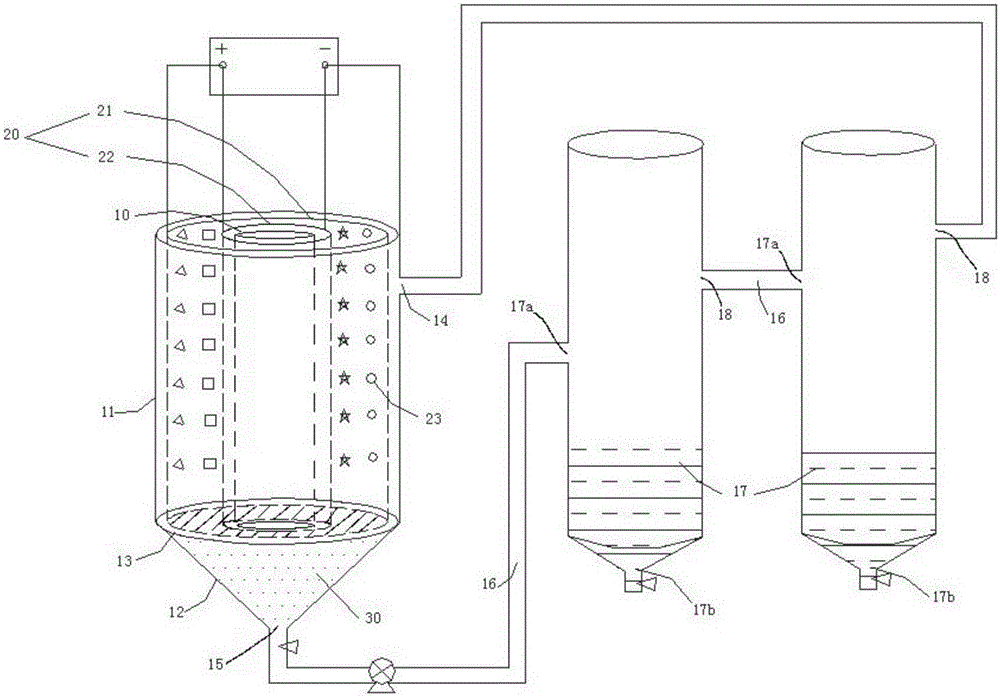

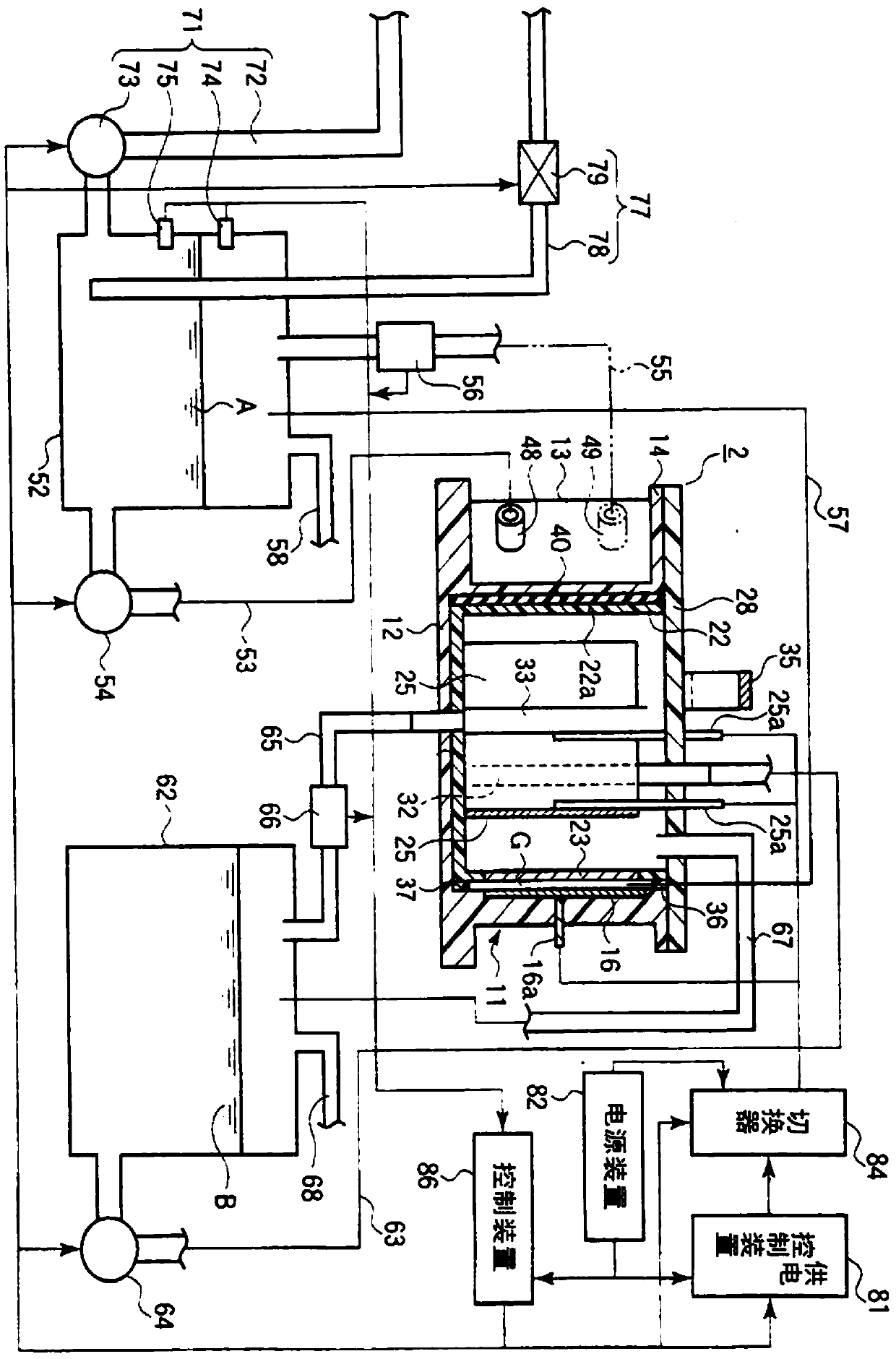

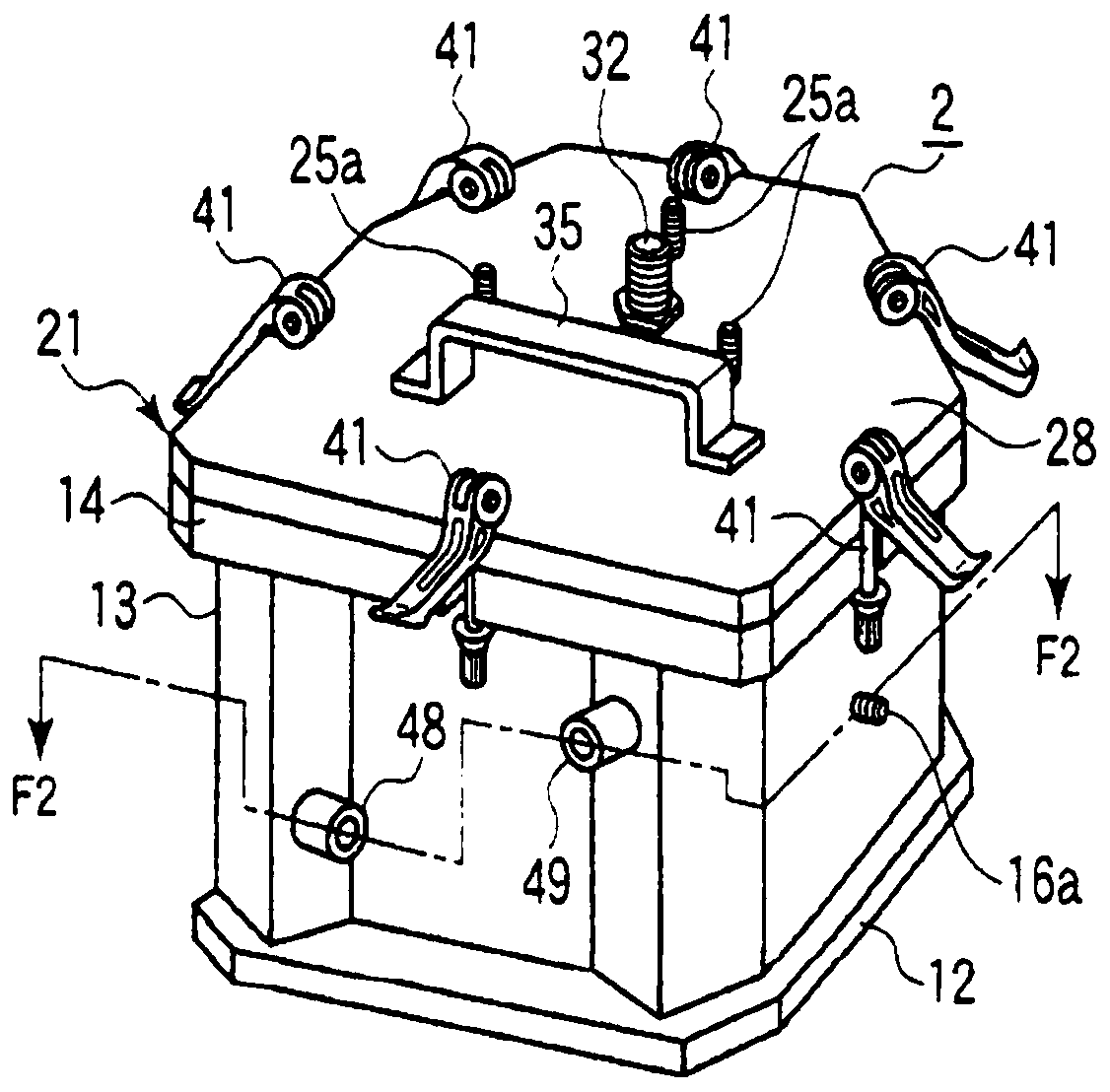

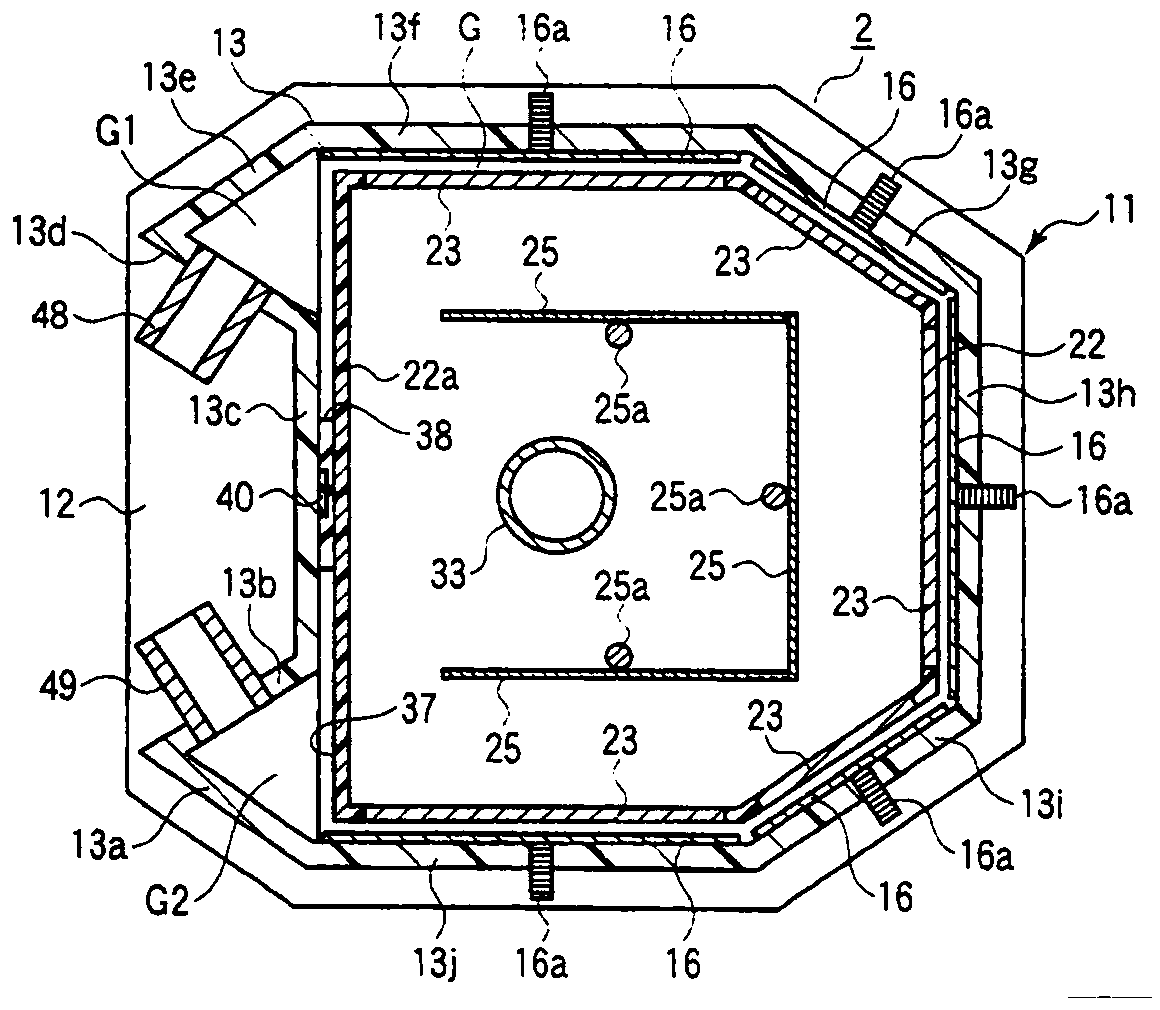

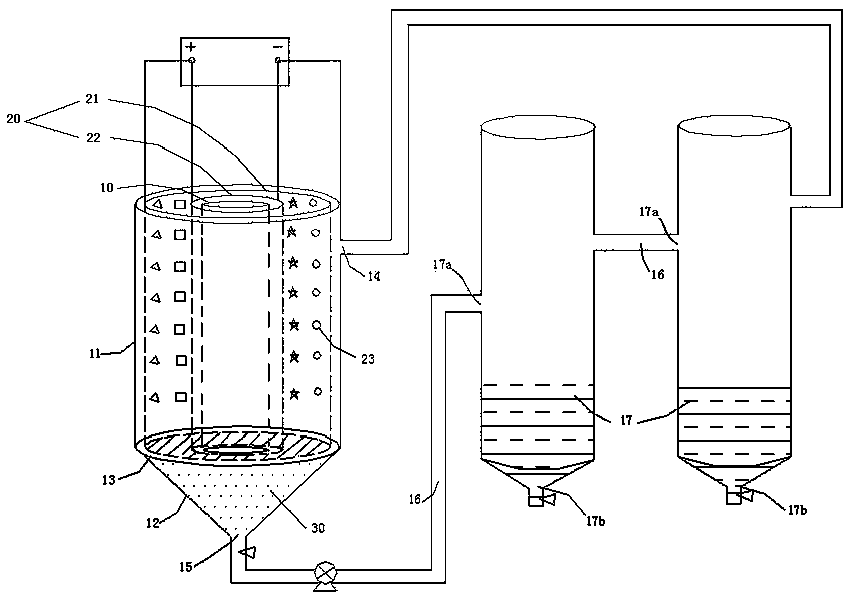

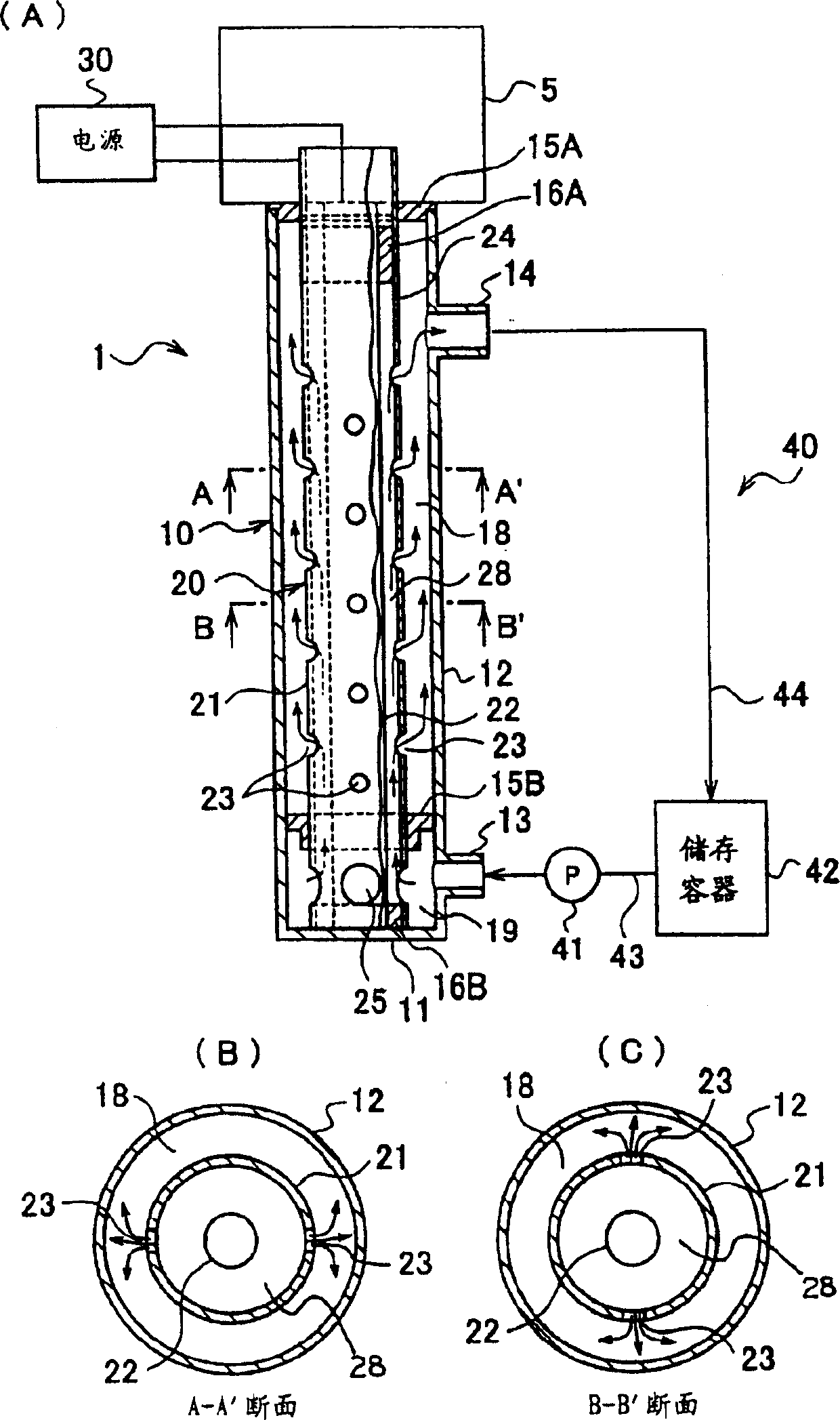

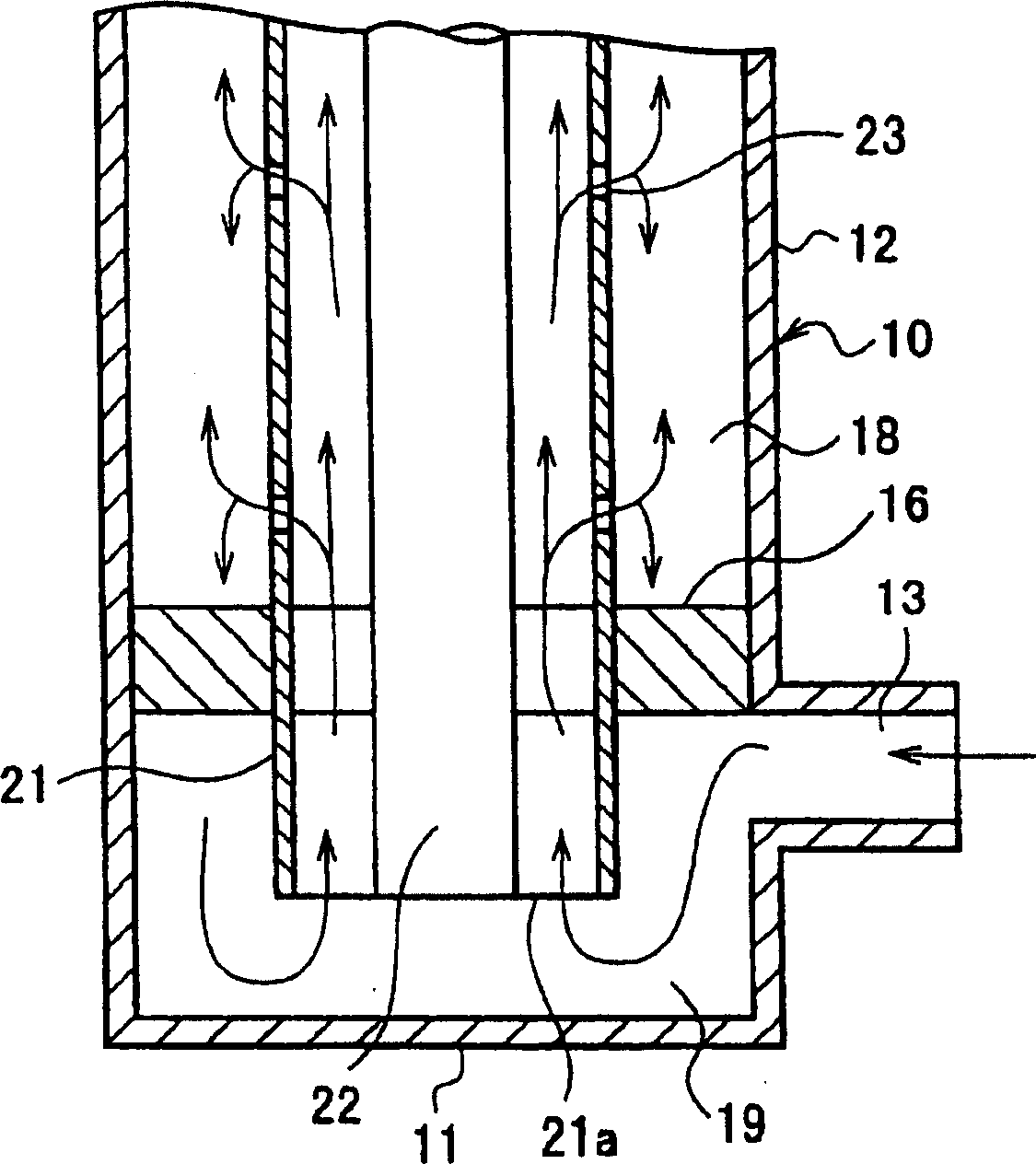

Electrolytic appts. and electrolytic treatment method

ActiveCN1519395AIncrease current densityIncrease the electrolysis areaCellsPhotography auxillary processesEngineeringHeat generation

To maintain compactibility, and to improve electrolytic efficiency while suppressing heat generation. A hollow electrode 21 in which many bore holes 23 are formed on the circumferential wall is arranged at the inside of a vertical, cylindrical treatment tank 10 in a state where an annular flow passage 18 is secured between the hollow electrode 21 and the inner wall of the treatment tank 10, and a rod-shaped electrode 22 is cocentrically arranged at the inside thereof. The circumferential wall 12 of the treatment tank 10 is provided with an introduction port 13 for introducing the liquid to be treated from the outside of the treatment tank 10 into the lower end of the hollow electrode 21, and an introduction-out port 14 for introducing-out the liquid to be treated flowed out from each bore hole 23 inside the treatment tank 10 at the upper end side of the hollow electrode 21 to the outside of the treatment tank 10.

Owner:DOWA METALS & MINING CO LTD

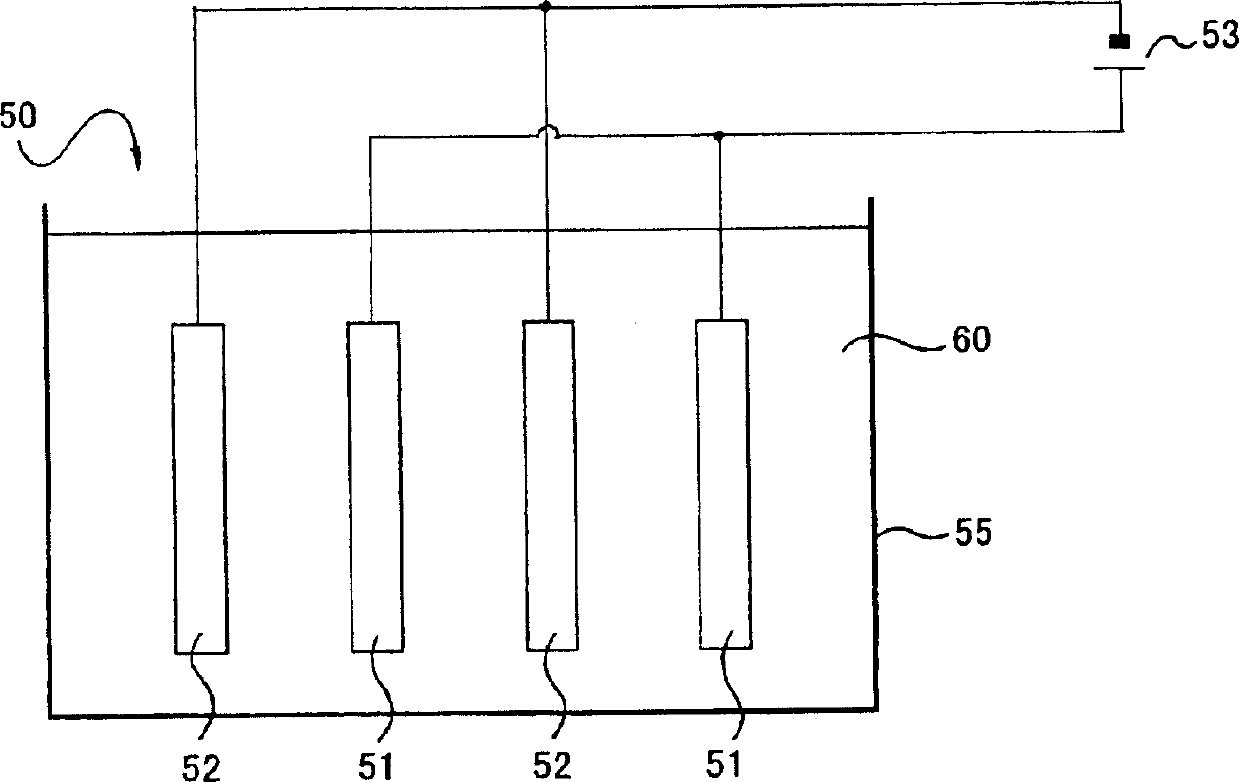

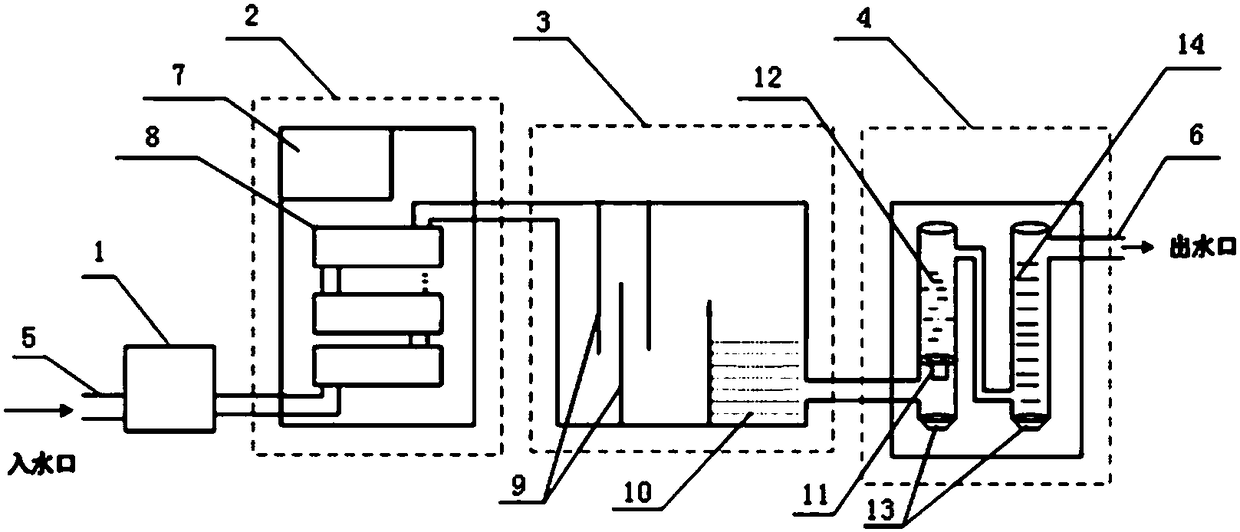

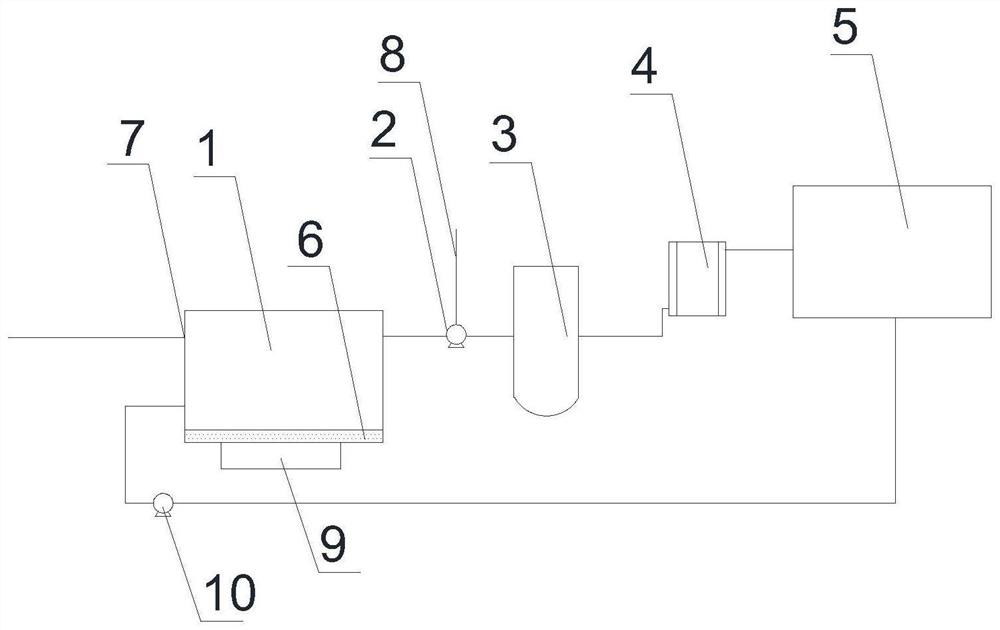

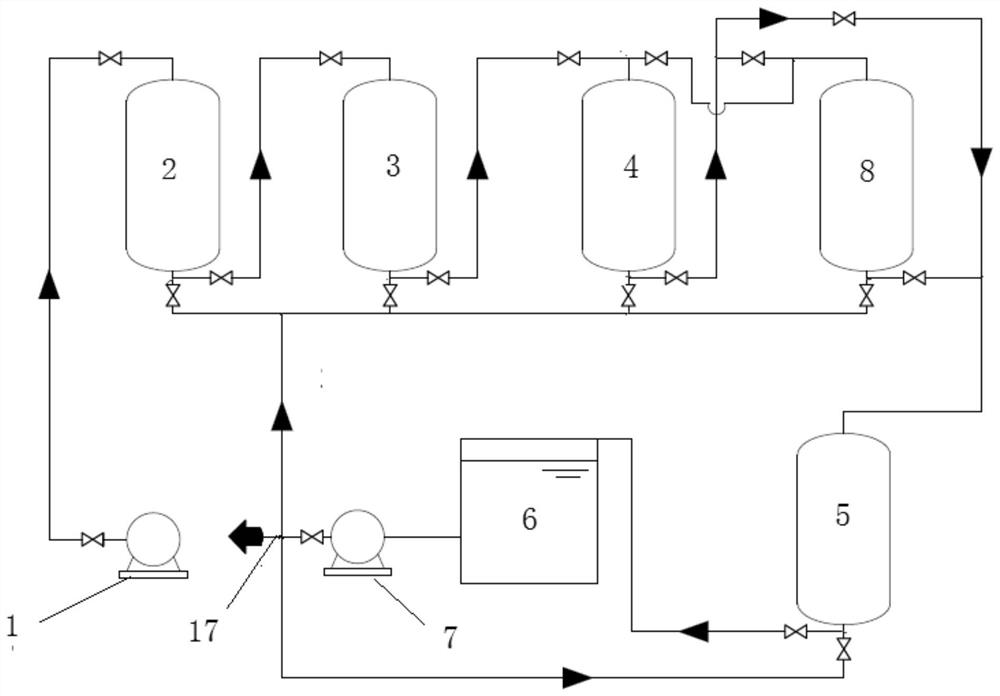

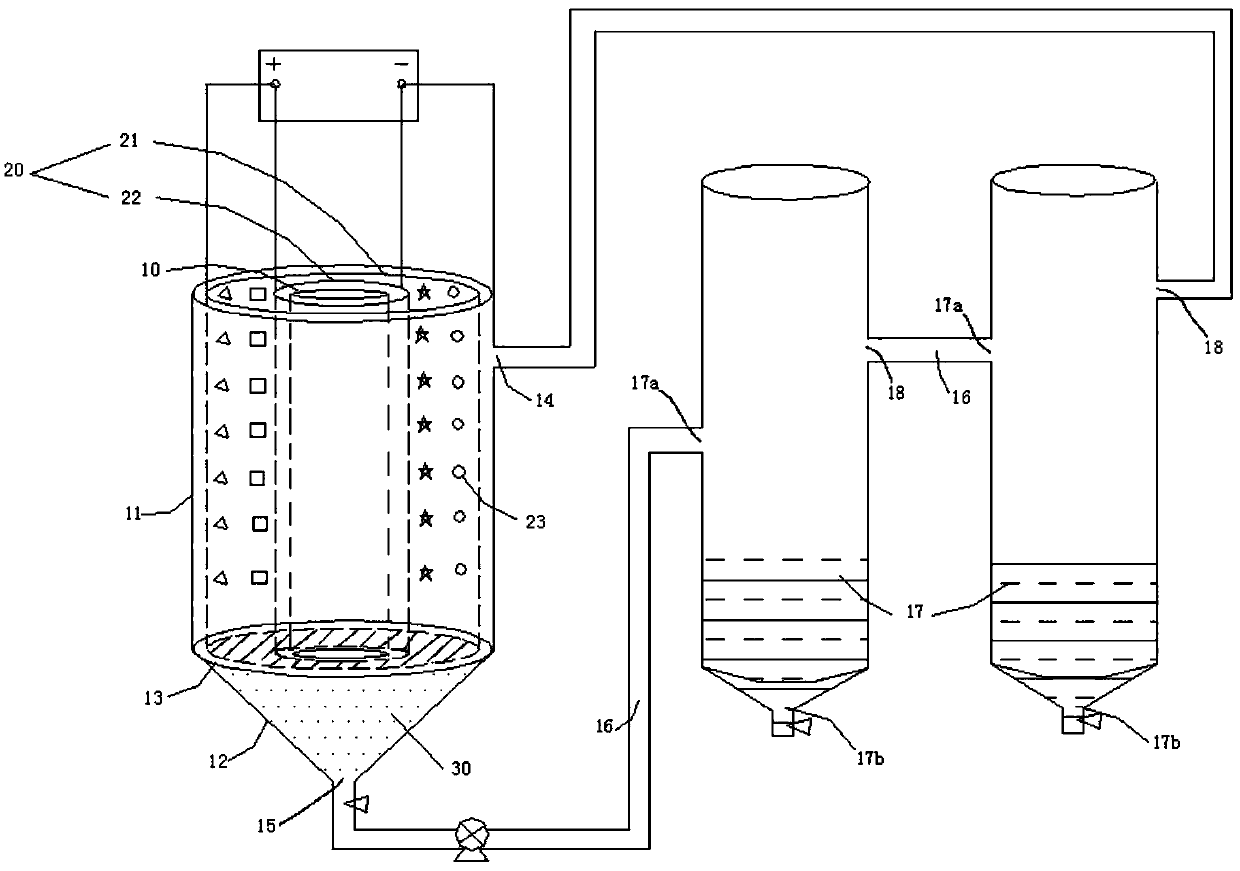

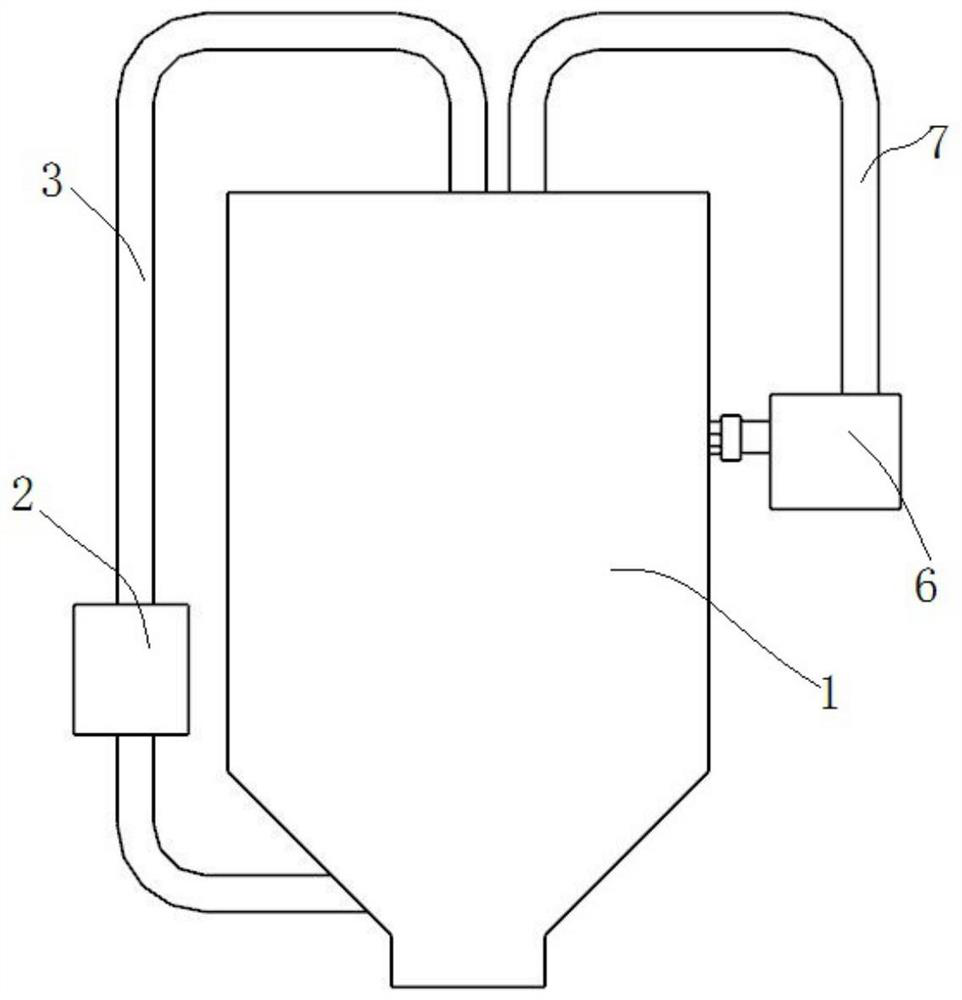

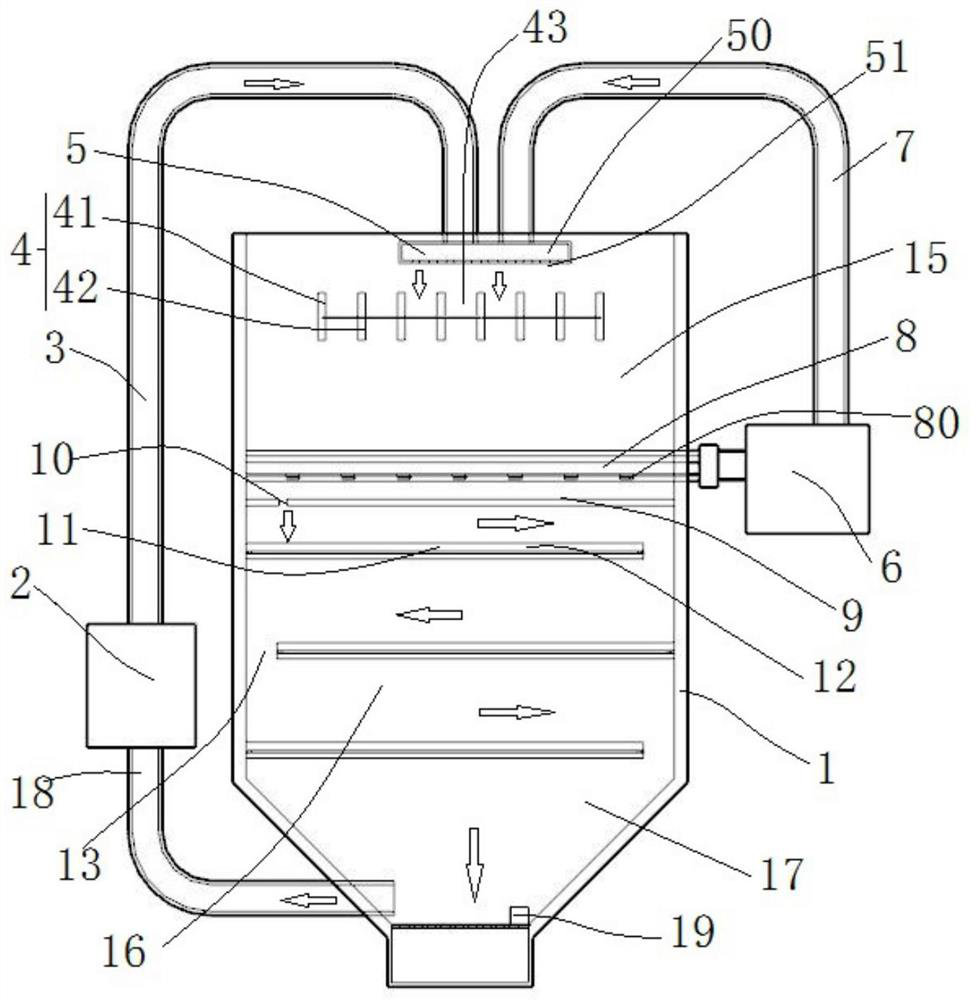

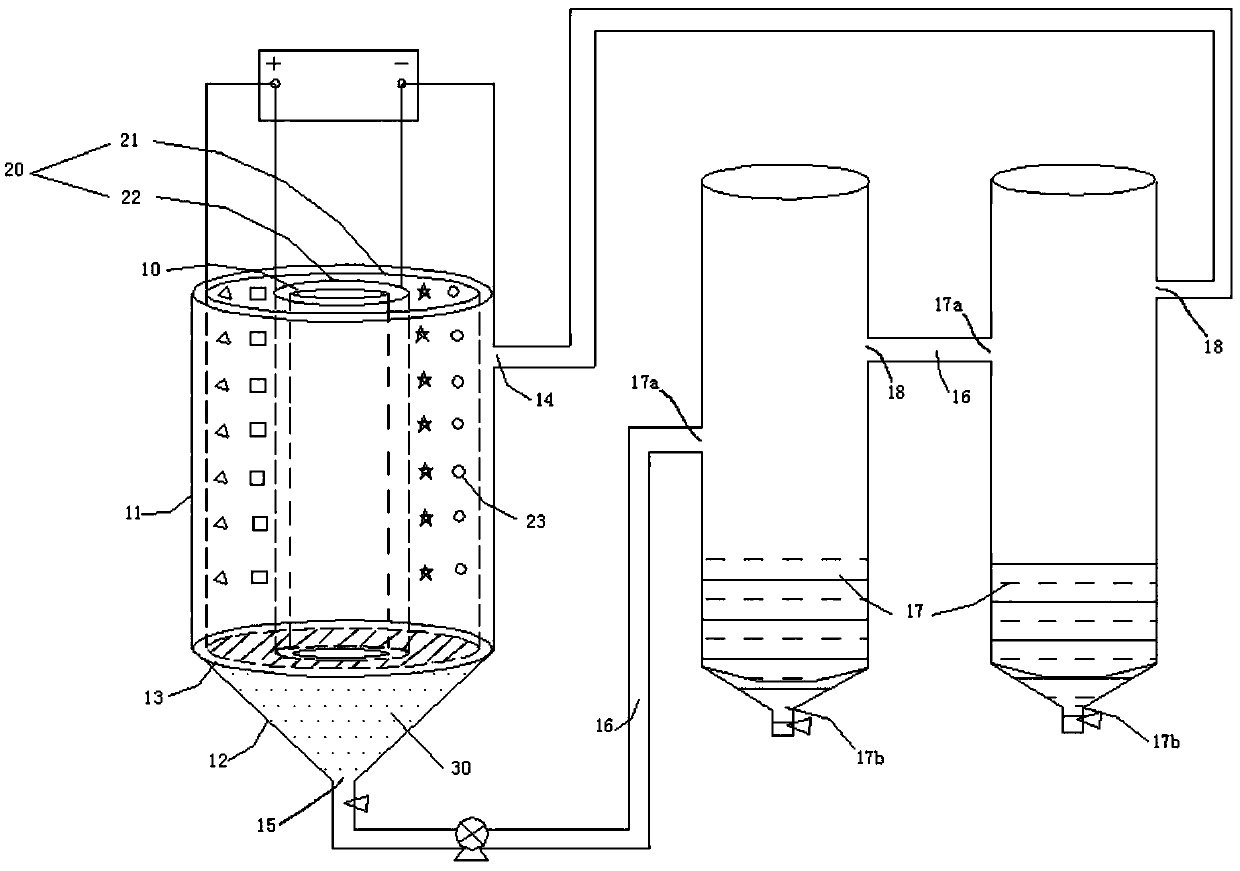

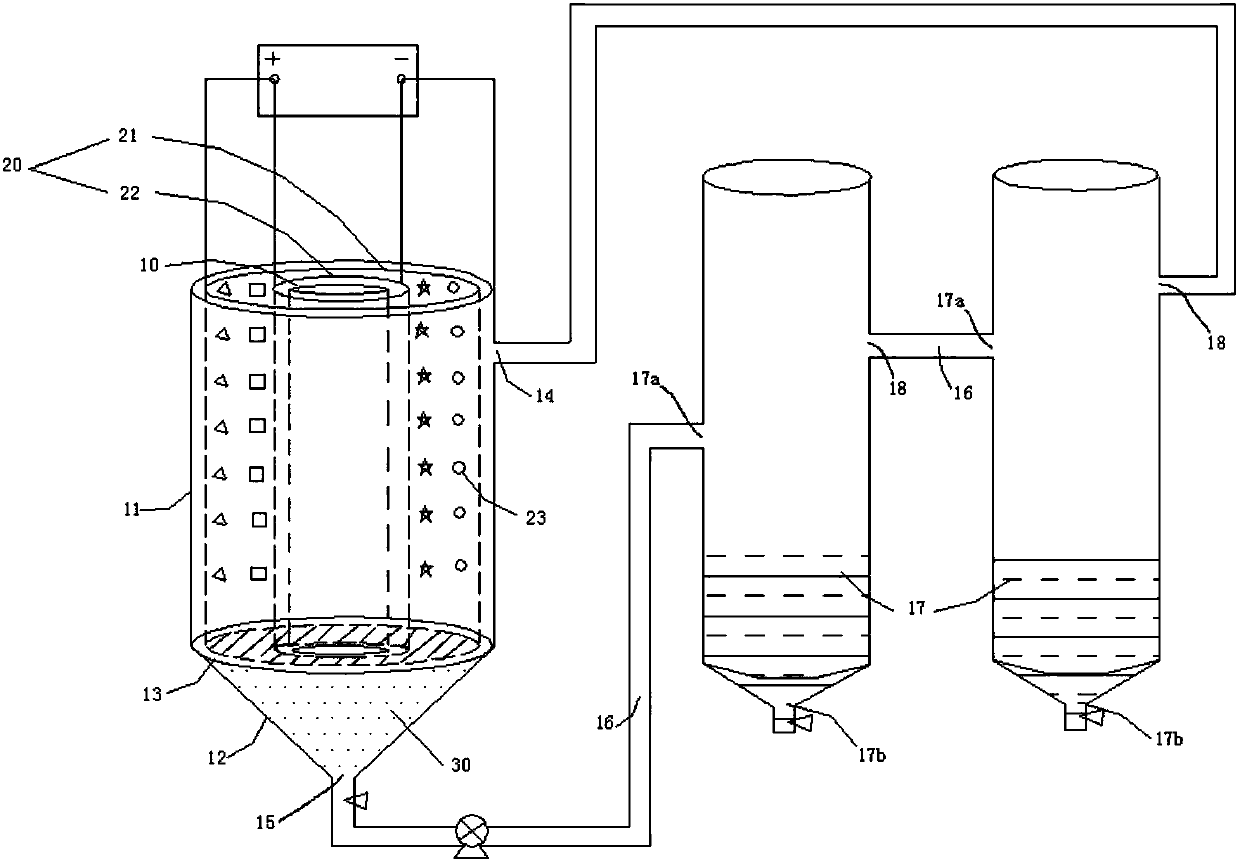

Multistage sewage electro-flocculation treatment system

ActiveCN108249648AImprove efficiencyImprove processing efficiencyTreatment involving filtrationMultistage water/sewage treatmentElectrolysisFiltration

The invention relates to a multistage sewage electro-flocculation treatment system which comprises a water pump, a host device, a sedimentation tank and a filtration and adsorption device, wherein thewater pump is connected with a water inlet and used for pumping sewage; the host device comprises a plurality of electro-flocculation modules connected sequentially and a displaying and monitoring module used for displaying a PH value, temperature, turbidity and water level information, adjusting the flow rate of the water pump and the electrolytic current of each of the electroflocculation modules and realizing multi-stage electrolysis; the sedimentation tank is connected with the host device and used for discharging the precipitated sewage after multistage filtration and adsorption. Compared with the prior art, the multistage sewage electro-flocculation treatment system provided by the invention has the advantages of multi-stage electrolytic precipitation, high efficiency, stable electrolytic current, water pump flow rate control, high efficiency and stability, applicability to heavy metals, reduced flow rate, improved purifying effect, self-cleaning, full water purification and thelike.

Owner:SHANGHAI UNIV OF ENG SCI

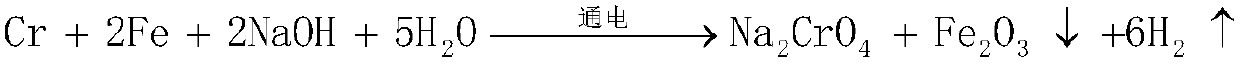

Method for preparing chromic anhydride by using ferrochromium

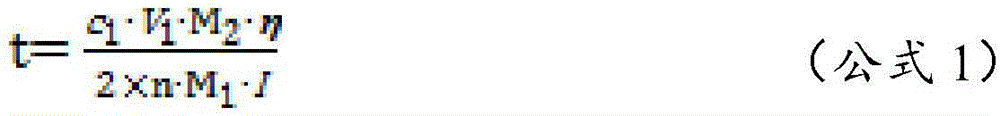

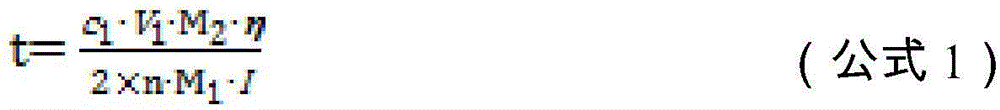

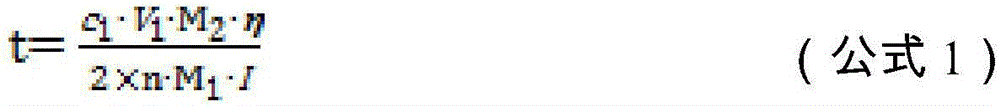

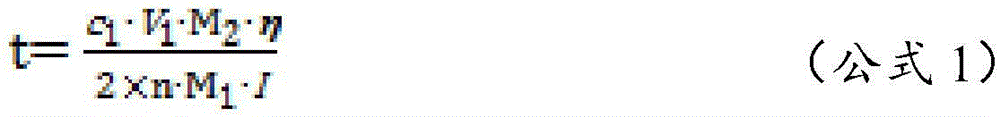

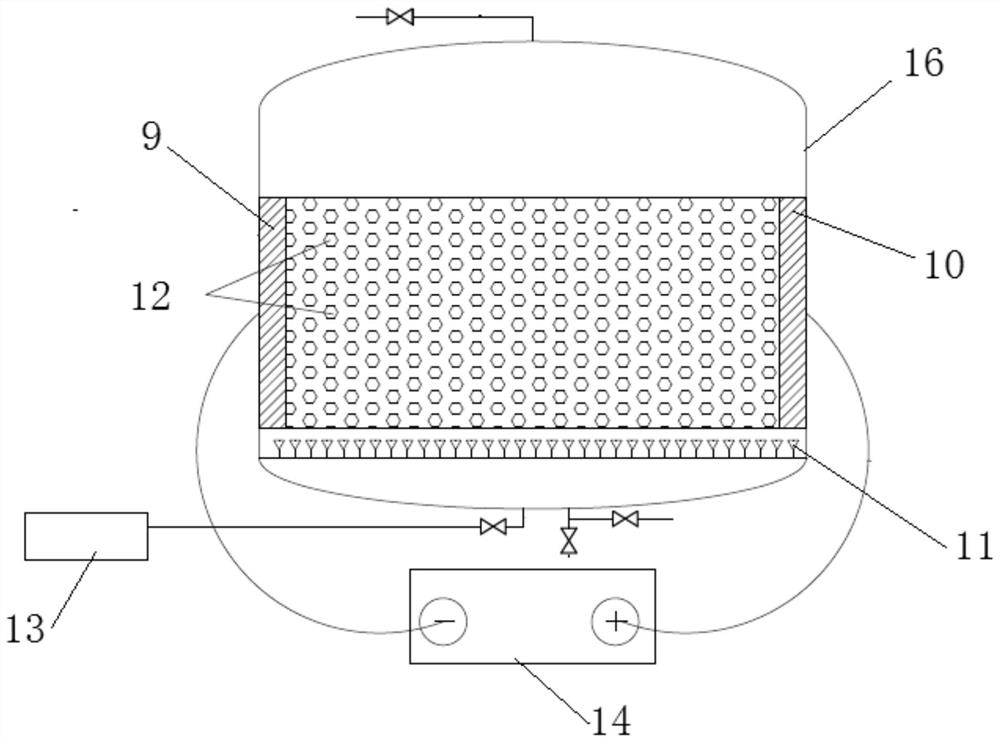

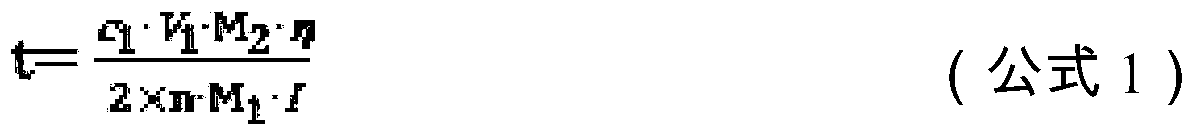

The invention relates to a method for preparing chromic anhydride by using ferrochromium, wherein the method comprises the steps: carrying out an electrolytic reaction by a self circulating mode, controlling the circulating reaction time according to the formula described in the specification, to obtain a high-concentration chromate solution, and carrying out a hydrothermal reaction, to obtain a high-purity chromate purification solution; preparing a chromate solution with the mass concentration of 20%-40% with the high-purity chromate purification solution, mixing the chromate solution with adichromate solution with the mass concentration of 23%-50% to prepare an anode mixed feed liquid, and carrying out an electrolytic reaction to obtain a dichromate solution; and adjusting the concentration of the obtained dichromate solution to 27%-73%, taking the obtained dichromate solution as a raw material, carrying out an electrocatalytic synthesis reaction to obtain a mixed solution of chromic acid and dichromate, and carrying out crystallization separation to obtain chromic anhydride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method for preparing high-purity chromate by using ferrochromium

The invention relates to a method for preparing high-purity chromate by using ferrochromium, wherein the method comprises the steps: providing an electrolytic device including an electrolytic tank, adouble-cathode device, a double-anode device, an insulating partition plate, a plurality of settling tanks and an electrode; carrying out an electrolytic reaction by a self circulating mode, automatically controlling the temperature at 20 DEG C-60 DEG C, and controlling the electrolyte solution circulating reaction time according to the formula 1 described in the specification, to obtain a high-concentration chromate solution; and inducing the high-concentration chromate solution into a reaction kettle, carrying out a hydrothermal reaction, under the pressure of 2 MPa-10 MPa, heating to the temperature of 180 DEG C-300 DEG C, carrying out a reaction for 2 h-12 h to obtain a hydrothermal reaction slurry, carrying out solid-liquid separation to obtain the high-purity chromate purification solution, and carrying out evaporation concentration, cooling crystallization and filtration separation to obtain the high-purity chromate product.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method for preparing chromium oxide green by using ferrochrome

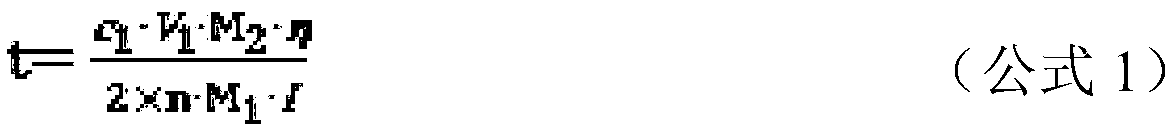

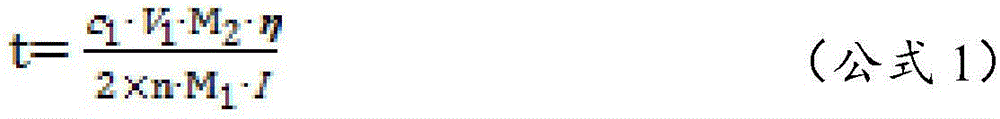

The invention relates to a method for preparing chromium oxide green by using ferrochrome. The method comprises the following steps: electrolysis devices which comprises an electrolytic cell, a double-cathode device, a double-anode device, an insulation partition plate, a plurality of sedimentation tanks and electrodes are provided; an electrolyte solution undergoes an electrolytic reaction in a self-circulation mode, the temperature of the electrolyte solution in the electrolytic cell is automatically controlled to be 20-60 DEG C, the circulating reacting time for the electrolyte solution is controlled according to a formula 1 being t=c1*V1*M2 *Eta / (2*n*M1*I), and solid-liquid separating treatment is carried out to obtain a high-concentration chromate solution; the high-concentration chromate solution is guided into a reaction kettle for carrying out hydrothermal reaction, under the pressure of 2-10 MPa, the chromate solution in the reaction kettle is heated to 180-280 DEG C and reacted for 2-12 hours to obtain a hydrothermal reaction slurry, and filtering separating treatment is carried out to obtain a chromium hydroxide solid; and calcinating treatment is carried out on the chromium hydroxide solid to obtain the chromium oxide green.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Three-dimensional electrolysis sewage treatment method

PendingCN112374666AAvoid annihilationAvoid wastingWater contaminantsWater/sewage treatment bu osmosis/dialysisTreated waterWater treatment

The invention relates to a three-dimensional electrolysis sewage treatment method, which comprises the following steps: S1, mixing sewage with a particle electrode, and adsorbing pollutants in the sewage on the particle electrode to obtain an adsorbed mixed solution; S2, dissolving oxygen into the adsorbed mixed solution, introducing the mixed solution with dissolved oxygen into a three-dimensional electrolytic cell, and performing three-dimensional electrolysis on the sewage by using a three-dimensional electrolysis system formed by the particle electrode and a cathode plate and an anode plate in the three-dimensional electrolytic cell; and S3, carrying out solid-liquid separation on the mixed solution subjected to three-dimensional electrolysis to obtain treated water and a particle electrode, and recycling the particle electrode obtained by separation. According to the method, the number of hydroxyl radicals generated in the three-dimensional electrolysis process can be increased, the utilization rate of the hydroxyl radicals is increased, energy consumption is reduced, and the electrolysis efficiency is improved.

Owner:中机高科(重庆)环保工程有限公司

Technology for removing tetrabromobisphenol A in wastewater based on iron-carbon micro-electrolysis technology

ActiveCN112979009AImprove conductivityHigh removal rateSpecific water treatment objectivesWater contaminantsActivated charcoal powderTetrabromobisphenol A

The invention discloses a process for removing tetrabromobisphenol A in wastewater based on an iron-carbon micro-electrolysis technology, which is specifically carried out according to the following steps: preparing a spherical iron-carbon filler which mainly comprises the following raw materials in parts by weight: 35-45 parts of scrap iron, 15-18 parts of graphite, 20-25 parts of activated carbon and 5-8 parts of a phenolic adhesive, adding the scrap iron into a vacuum smelting furnace for smelting, spraying the smelted liquid iron out through an atomizing nozzle, conducting cooling to form spherical powder, punching hole grooves in the surface of the iron scrap spherical powder, smashing and mixing graphite and activated carbon, then adding the mixture, the iron scrap spherical powder and a phenolic adhesive into a centrifugal machine together, and preparing an iron-carbon filler; introducing the wastewater into a purification tank, and adjusting the pH value of the wastewater to 3-4; enabling the wastewater to pass through the filler in an electrolytic purification pipe; and adding sodium hydroxide into a purification cylinder to enable the pH value of the purified water to be 6-10, conducting stirring, standing and precipitating, and taking supernate of the purified water. The method is simple in process, low in cost and suitable for wide popularization.

Owner:中日友好环境保护中心 +1

Method for joint production of chromium oxide green, iron oxide red and high-purity chromate by electrolyzed ferrochromium

The invention relates to a method for joint production of chromium oxide green, iron oxide red and high-purity chromate by electrolyzed ferrochromium. The method comprises the following steps: an electrolysis reaction is performed by adopting a self-circulating mode; the temperature is automatically controlled within 20-60 DEG C; the circulating reaction time is controlled according to a formula I; high-concentration chromate solution and solid slag are obtained; the gravity sorting is performed on the obtained solid slag to obtain iron hydroxide; the iron oxide red is obtained by calcining at a temperature of 500-800 DEG C; the hydrothermal reaction is performed on the obtained high-concentration chromate solution to obtain a high-purity chromate purified solution and a chromium hydroxide solid; the high-purity chromate purified solution is filtered, crystallized and separated to obtain a high-purity chromate product; and the chromium hydroxide solid is calcined to obtain the chromium oxide green.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

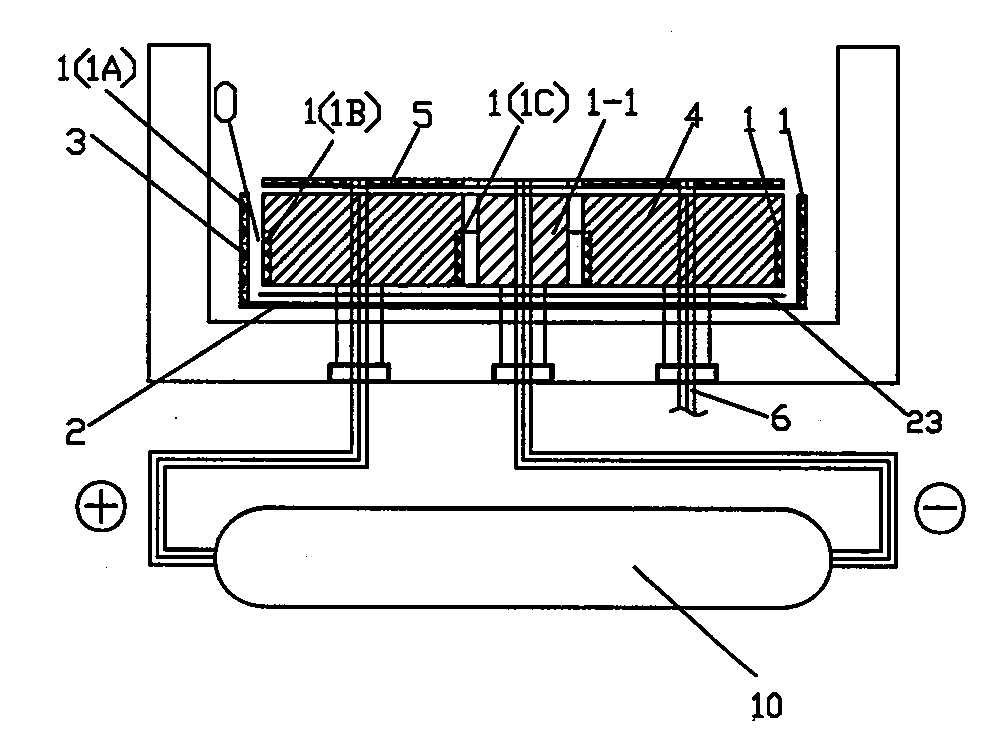

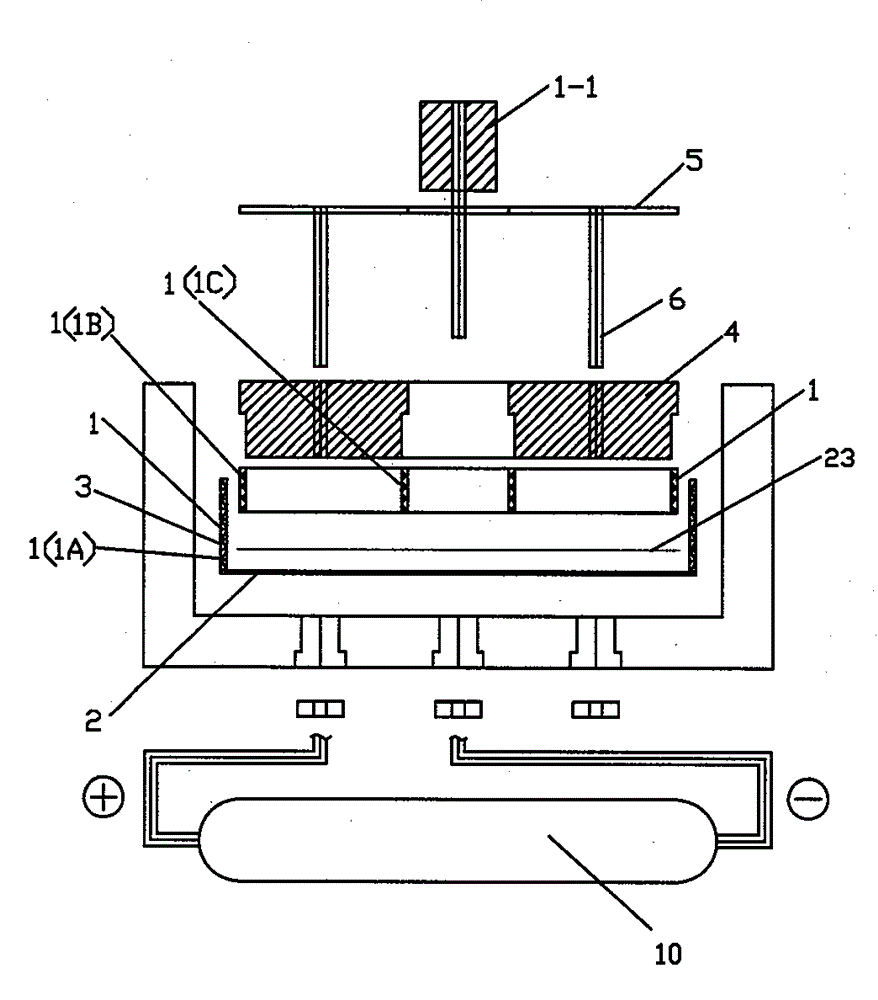

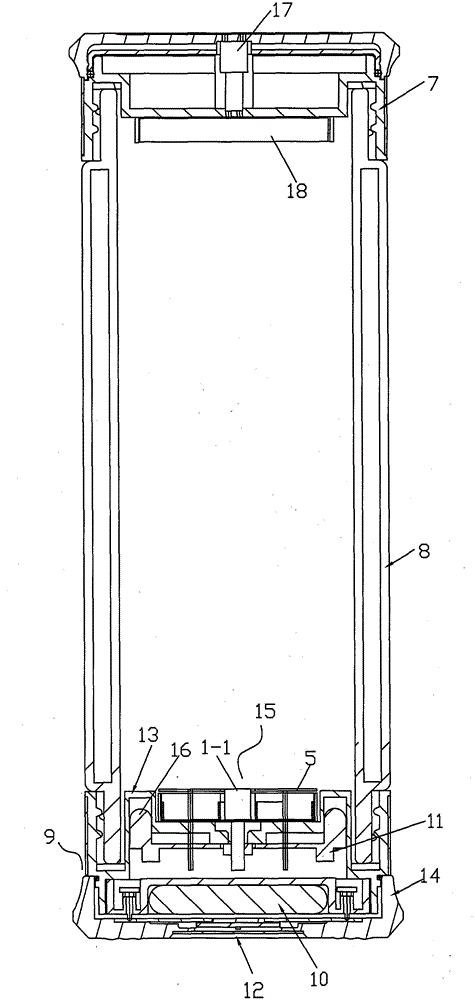

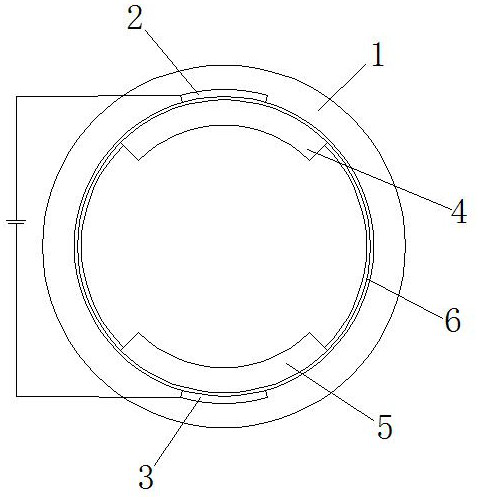

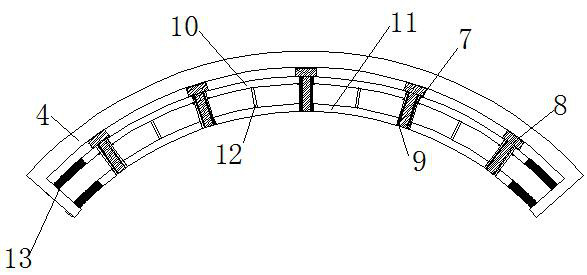

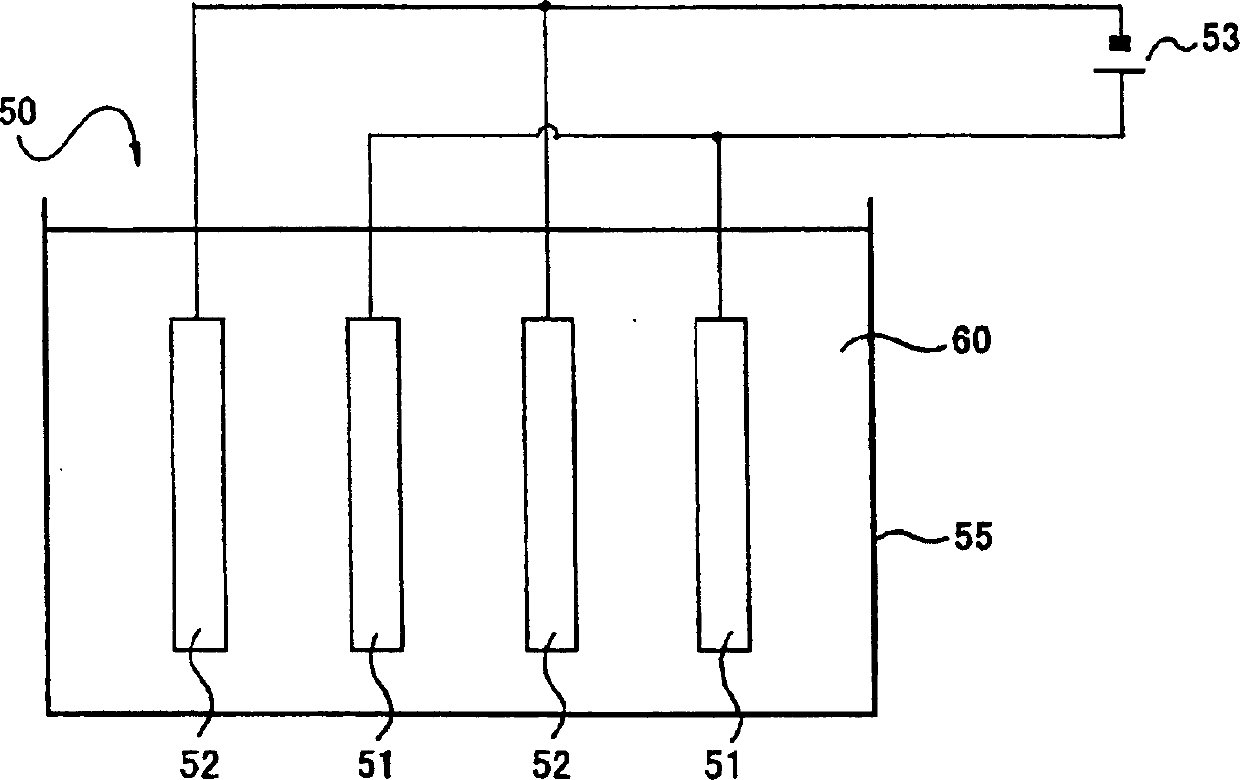

An integrated multi-point surface electrolysis module device and electrolysis cup

The invention discloses an integrated multi-point-surface electrolysis module device, belonging to water electrolyzers and relating to drinking water electrolysis devices. The device consists of a plurality of cathode or anode rings (1) made from inert metal materials, wherein the cathode or anode rings (1) are of staggered distribution from inside to outside, so as to form a plurality of electrolysis zones of big and small gaps. The invention further discloses an electrolysis cup with the integrated multi-point-surface electrolysis module device. According to the integrated multi-point-surface electrolysis module device, the electrolysis area is large, the occupied internal space of the cup is small, the efficiency is high, the power consumption is low, and drinking water can be effectively electrolyzed, so that the drinking of a human body is healthier.

Owner:王来珠

Cerium-doped iron oxyhydroxide modified titanium foam material, preparation method thereof, and application in water treatment

ActiveCN109261140BIncrease precipitation speedGood application effectWater treatment parameter controlOther chemical processesElectrolytic agentCyclic voltametry

The invention discloses a titanium foam material modified with cerium-doped iron oxyhydroxide and a preparation method thereof. A titanium foam plate is used as a working electrode, a platinum sheet is used as a counter electrode, and a saturated calomel electrode is used as a reference electrode to form a three-electrode system. The aqueous solution of cerium chloride, sodium sulfate, polyvinylpyrrolidone and hydrogen peroxide is used as the electrolyte, and the cyclic voltammetry is used to sweep the circle, and then the working electrode is taken out, washed and dried to obtain the final product; the invention also discloses the doped Application of cerium iron oxyhydroxide modified titanium foam material in water treatment. The invention uses porous titanium foam as a matrix, and the surface is modified with cerium-doped iron oxyhydroxide, which improves the applicability and activity of iron oxyhydroxide, has higher porosity, adsorption and oxidation capabilities, and can be used as an adsorption filler, filter core or electrode When used in water treatment, it will not cause secondary pollution to the treated water, and the preparation process has good controllability and stability.

Owner:SHENGSHI LANDSCAPE GRP CO LTD

Method for preparing high-purity chromate by utilizing ferrochrome

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method for preparing iron oxide red by using ferrochromium

The invention relates to a method for preparing iron oxide red by using ferrochromium, wherein the method comprises the following steps: a first step, providing a preparation device including an electrolytic tank, a double-anode device, a double-cathode device, an insulating partition plate, a plurality of settling tanks and an electrode; a second step, carrying out an electrolytic reaction by a self circulating mode, automatically controlling the temperature at 20 DEG C-60 DEG C, and controlling the electrolyte solution circulating reaction time according to the formula 1 described in the specification, to obtain a high-concentration chromate solution and a solid slag material; a third step, carrying out conventional gravity magnetic sorting of the solid slag material obtained in the second step, and removing inclusion small-particle ferrochromium to obtain iron hydroxide with the particle size of 30 [mu]m-74 [mu]m; and a fourth step, calcining the iron hydroxide with the particle size of 30 [mu]m-74 [mu]m at the temperature of 500 DEG C-800 DEG C for about 1 h-4 h to obtain iron oxide red.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method for preparing dichromate by using ferrochrome

The invention discloses a method for preparing dichromate by using ferrochrome. The method comprises the following steps: an electrolyte solution undergoes an electrolytic reaction in a self-circulation mode, the temperature of the electrolyte solution in an electrolytic cell is automatically controlled to be 20-60 DEG C, the circulating reacting time for the electrolyte solution is controlled according to a formula 1 being t=c1*V1*M2 *Eta / (2*n*M1*I), and a high-concentration chromate solution is obtained; hydrothermal reaction is carried out on the high-concentration chromate solution to obtain a high-purity chromate solution; the high-purity chromate solution is prepared into a chromate solution with the weight percent concentration of 20%-40%, and the prepared chromate solution is mixed with a dichromate solution with the weight percent concentration of 23%-50% to prepare an anode mixed feeding liquid; and a cathode mixed feeding liquid is provided, and the electrolytic reaction is carried out on the anode mixed feeding liquid and cathode mixed feeding liquid to obtain a dichromate solution.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

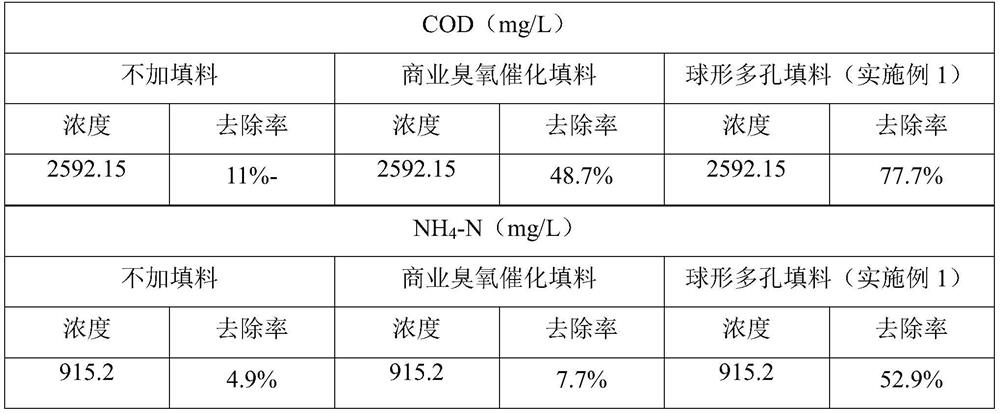

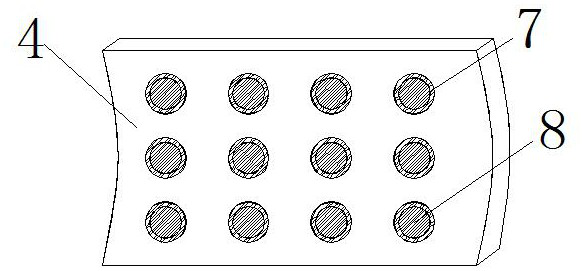

Spherical porous filler and electrolytic oxidation system for treating organic matters in heavy salt water

InactiveCN113754149AImprove oxidation efficiencyEfficient electrolytic treatmentWater treatment compoundsTreatment involving filtrationNitrogen gasBall mill

The invention discloses a spherical porous filler and an electrolytic oxidation system for treating organic matters in heavy salt water. The spherical porous filler is prepared by the following method: cleaning blast furnace fly ash, performing drying, performing grinding with a ball mill, mixing the ground blast furnace fly ash with clay, adding deionized water, and performing granulating; and performing sintering under the protection of nitrogen, and cooling to room temperature to obtain the spherical porous filler. The spherical porous filler provided by the method can greatly promote the ozonation efficiency. The filler can serve as a three-dimensional conductive electrode in an advanced oxidation device for treating organic matters in high-salinity water, the electrolysis area is greatly increased, and efficient electrolysis treatment of the organic matters in the high-salinity water is achieved. The main components in the raw materials of the spherical porous filler are iron element and carbon element, the iron element and the carbon element can form a Fe-C micro-electrolysis system in water, iron ions formed in the micro-electrolysis process can promote ozonolysis, the forming speed of hydroxyl free radicals in water is increased, and the catalytic ozonation efficiency is greatly improved.

Owner:TIANJIN POLYTECHNIC UNIV

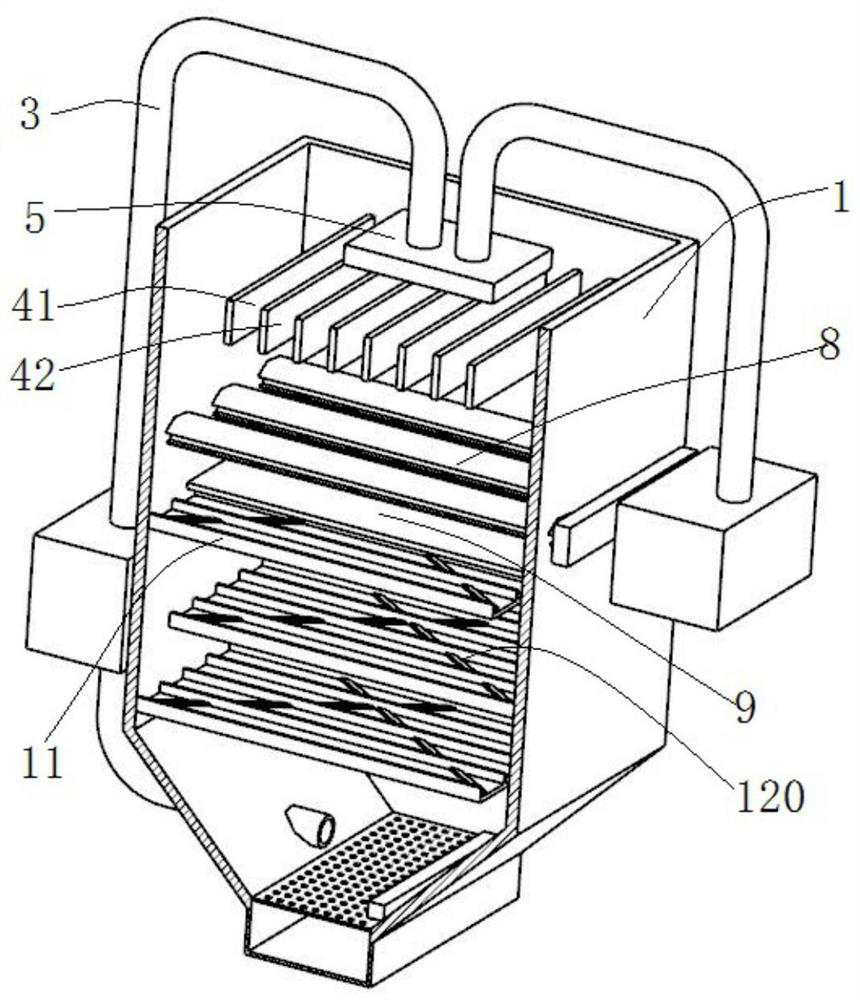

Electric flocculation device

PendingCN112897651ADoes not affect flocculation speedIncrease the electrolysis areaWater/sewage treatment apparatusElectrolysisElectro flocculation

The invention relates to the technical field of wastewater treatment, and discloses an electric flocculation device, which comprises a machine shell, an upper contact is fixedly installed on the upper surface in the machine shell, a lower contact is fixedly installed on the lower surface in the machine shell, an anode plate located below the upper contact is movably connected into the machine shell in a sleeved mode, a cathode plate located above the lower contact is movably connected into the machine shell in a sleeved mode, connecting rings are fixedly installed on the two sides of an anode plate and the two sides of the cathode plate, and an outer bent plate is movably installed at the bottom of the anode plate. According to the electric flocculation device, after bubbles adhere to the periphery of a conductive rod, the water pressure borne by an outer sleeve is reduced at the moment, the outer sleeve moves downwards, the lower end of a gas channel is exposed in the bubbles, the outer portions of the bubbles enter the upper portion of an inner bent plate under the action of the water pressure at the moment, a conductive rod is always exposed in wastewater, and a maximum electrolysis area is kept, therefore, in the electric flocculation process, the flocculation speed is not influenced by water electrolysis.

Owner:左海霞

Method for joint production of chromium oxide green, iron oxide red and high-purity chromate by electrolytic ferrochromium

The invention relates to a method for joint production of chromium oxide green, iron oxide red and high-purity chromate by electrolyzing ferrochrome, comprising the steps of: adopting a self-circulation method for electrolytic reaction, automatically controlling the temperature at 20°C to 60°C, and controlling according to formula 1 Circulate the reaction time to obtain high-concentration chromate solution and solid slag; carry out gravity separation on the obtained solid slag to obtain iron hydroxide, and calcinate at 500°C to 800°C to obtain iron oxide red; The high-concentration chromate solution is subjected to hydrothermal reaction to obtain a high-purity chromate purification solution and chromium hydroxide solid; the high-purity chromate purification solution is filtered and crystallized to obtain a high-purity chromate product; Chromium oxide solid is calcined to obtain chromium oxide green.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method for preparing chromium oxide green by using ferrochrome

ActiveCN107585788BShort production processReduce consumptionElectrolysis componentsFiltrationEvaporation

The invention relates to a method for preparing chromium oxide green by using ferrochromium, wherein the method comprises the steps: providing an electrolytic device including an electrolytic tank, adouble-cathode device, a double-anode device, an insulating partition plate, a plurality of settling tanks and an electrode; adopting an ammonium water salt system as an electrolyte solution, carryingout an electrolytic reaction by a self circulating mode, automatically controlling the temperature at 20 DEG C-60 DEG C, and controlling the electrolyte solution circulating reaction time according to the formula 1 described in the specification, to obtain an chromic acid ammonium salt solution after the reaction; and successively carrying out evaporation concentration, cooling crystallization and filtration separation of the chromic acid ammonium salt solution to obtain an ammonium chromate solid, and calcining the ammonium chromate solid for 2 h-12 h at the temperature of 950 DEG C-1100 DEGC to obtain chromium oxide green.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

A process for removing tetrabromobisphenol-a in wastewater based on iron-carbon micro-electrolysis technology

ActiveCN112979009BImprove conductivityHigh removal rateSpecific water treatment objectivesWater contaminantsActivated charcoal powderTetrabromobisphenol A

The invention discloses a process for removing tetrabromobisphenol A in wastewater based on iron-carbon micro-electrolysis technology, which is specifically carried out according to the following steps: preparing spherical iron-carbon fillers, and the iron-carbon fillers mainly include the following raw materials in parts by weight: iron filings 35-45 parts, 15-18 parts of graphite, 20-25 parts of activated carbon, and 5-8 parts of phenolic adhesive, add the iron filings into the vacuum melting furnace for smelting, spray the smelted liquid iron through the atomizing nozzle, and cool it to form a spherical shape The surface of the spherical powder of iron filings is filled with holes and grooves, and the graphite and activated carbon are crushed and mixed, and then added to the centrifuge together with the spherical powder of iron filings and phenolic adhesive to prepare iron-carbon fillers; the waste water is passed into the purification tank Inside, adjust the pH value of the waste water to be between 3-4; pass the waste water through the packing in the electrolytic purification tube; add sodium hydroxide to the purification cylinder to make the pH of the purified water 6-10, stir and let stand for precipitation, and take the purified water. The supernatant of water; the process of the invention is simple, the cost is low, and it is suitable for wide popularization.

Owner:中日友好环境保护中心 +1

Utilize ferrochromium to prepare the method for chromic anhydride

The invention relates to a method for preparing chromic anhydride by using ferrochromium, wherein the method comprises the steps: carrying out an electrolytic reaction by a self circulating mode, controlling the circulating reaction time according to the formula described in the specification, to obtain a high-concentration chromate solution, and carrying out a hydrothermal reaction, to obtain a high-purity chromate purification solution; preparing a chromate solution with the mass concentration of 20%-40% with the high-purity chromate purification solution, mixing the chromate solution with adichromate solution with the mass concentration of 23%-50% to prepare an anode mixed feed liquid, and carrying out an electrolytic reaction to obtain a dichromate solution; and adjusting the concentration of the obtained dichromate solution to 27%-73%, taking the obtained dichromate solution as a raw material, carrying out an electrocatalytic synthesis reaction to obtain a mixed solution of chromic acid and dichromate, and carrying out crystallization separation to obtain chromic anhydride.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

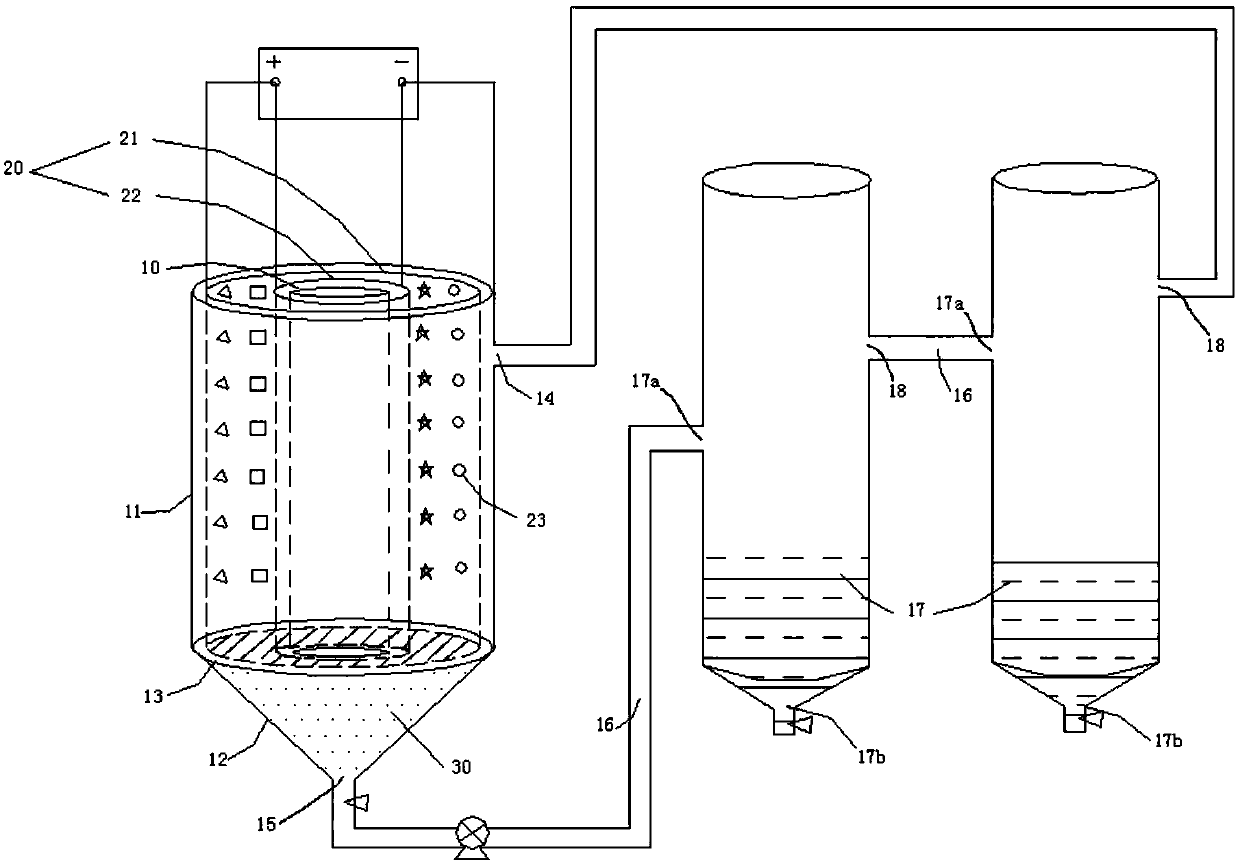

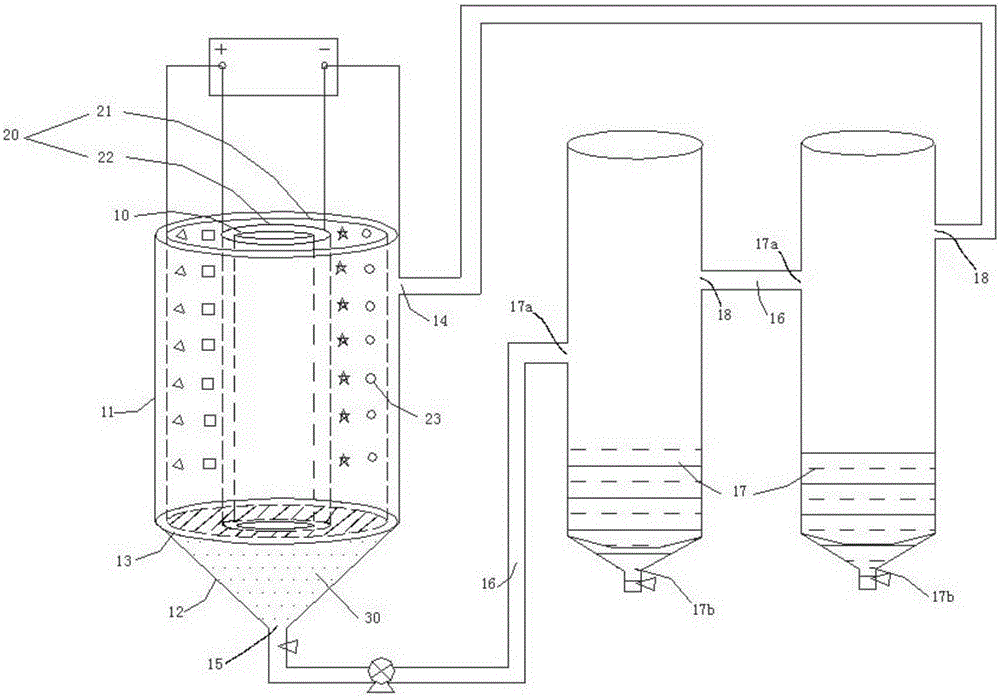

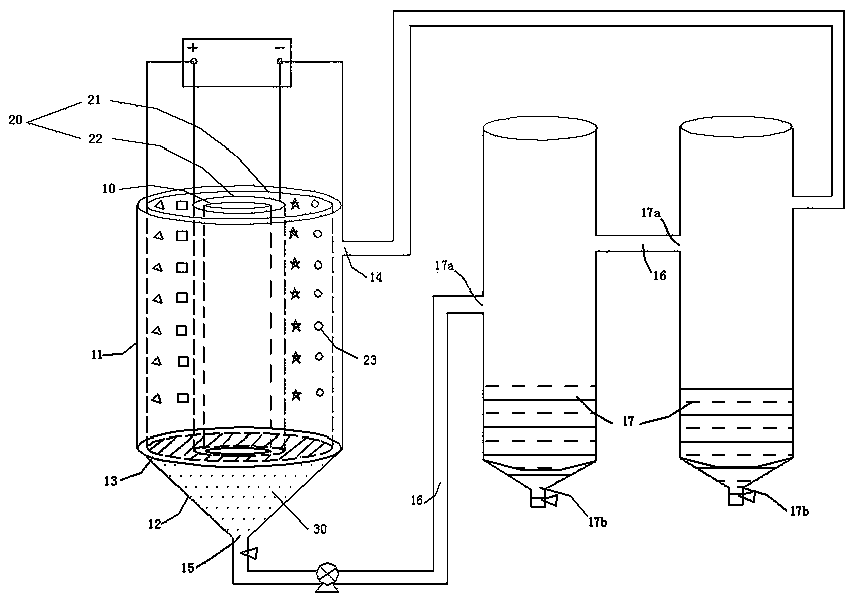

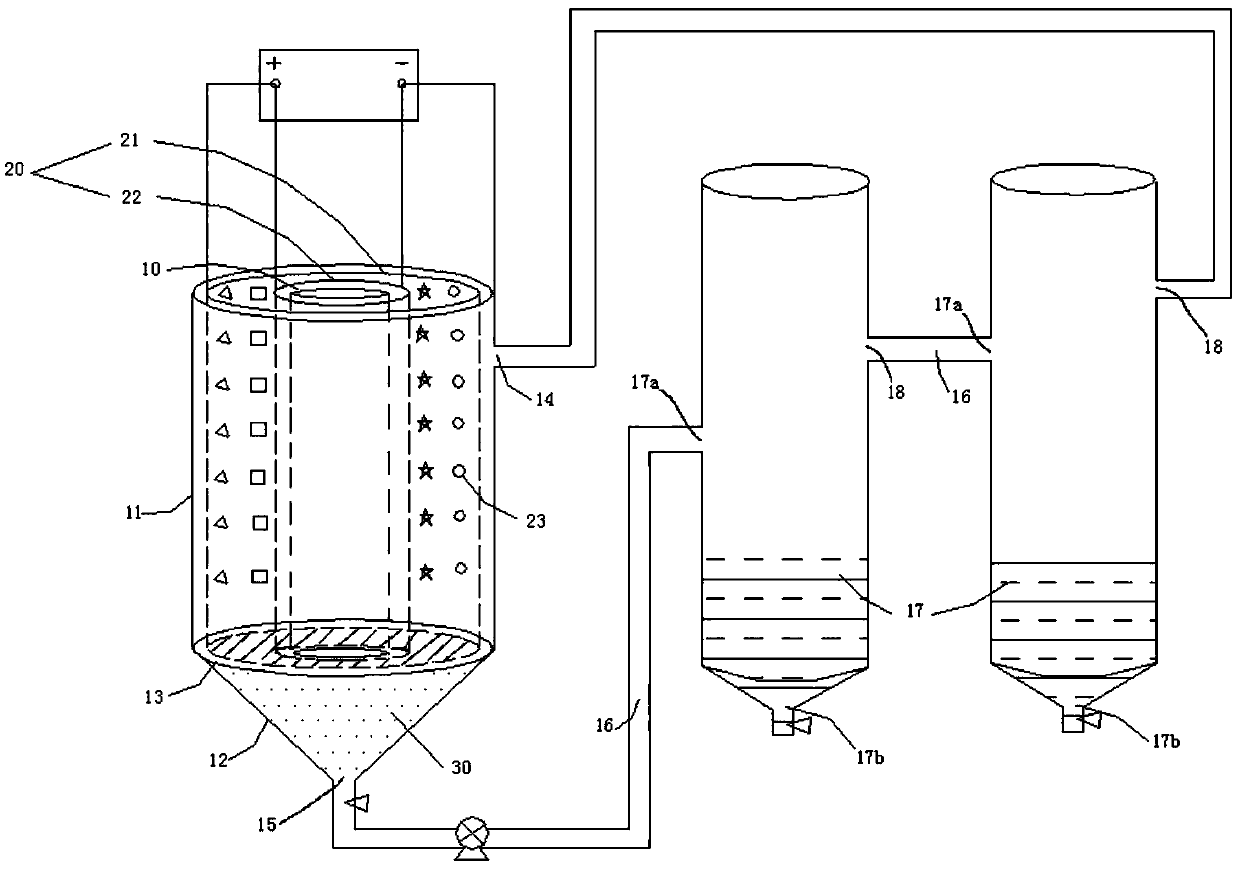

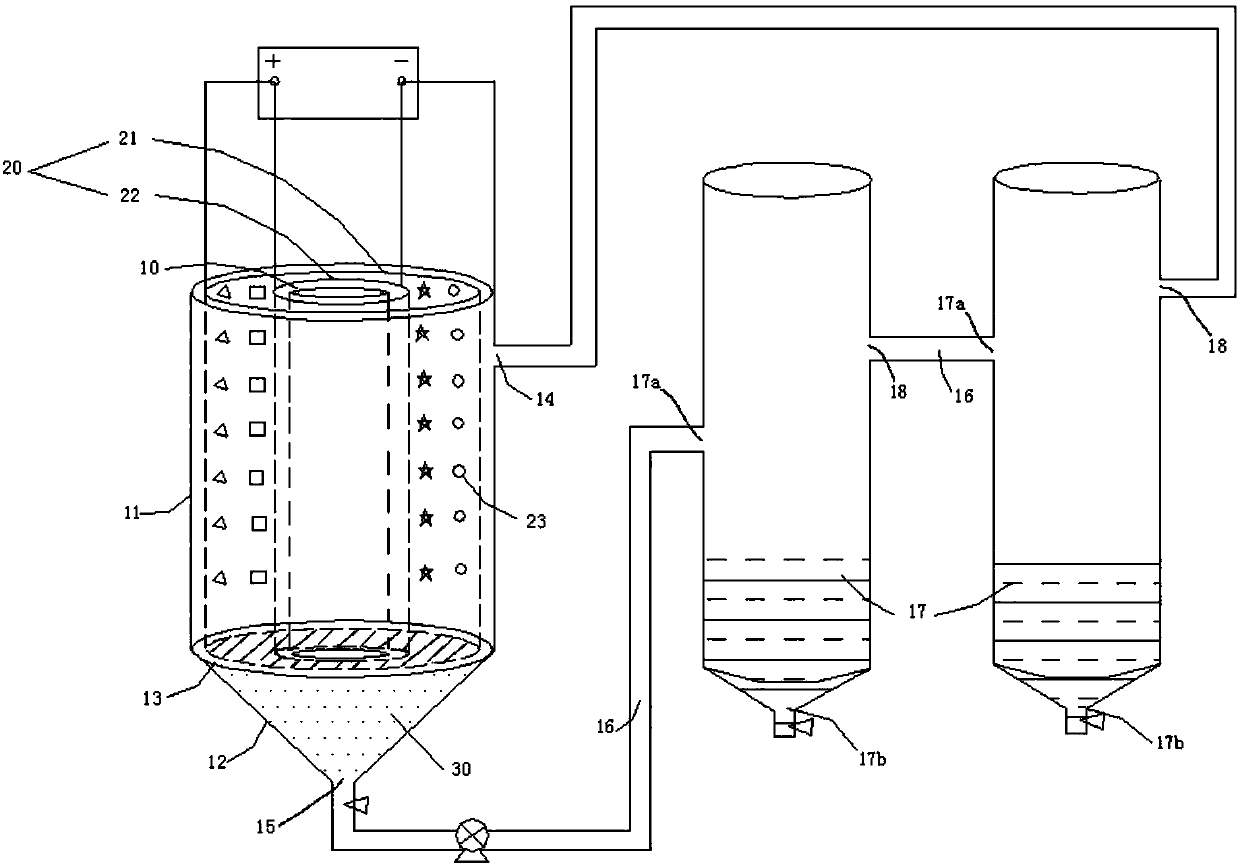

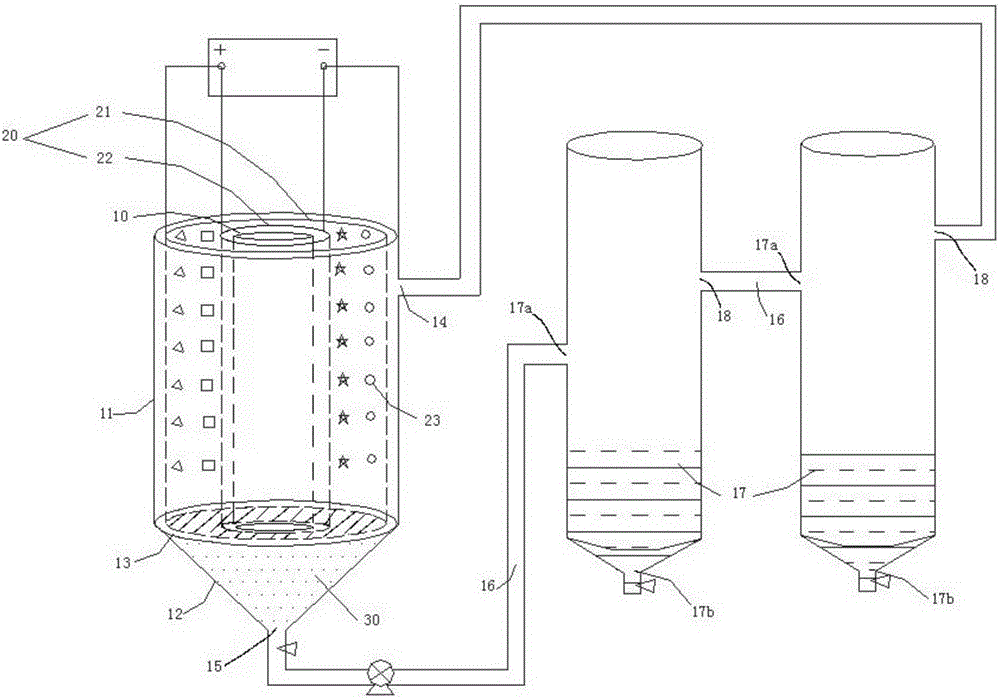

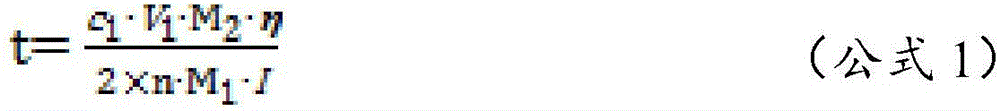

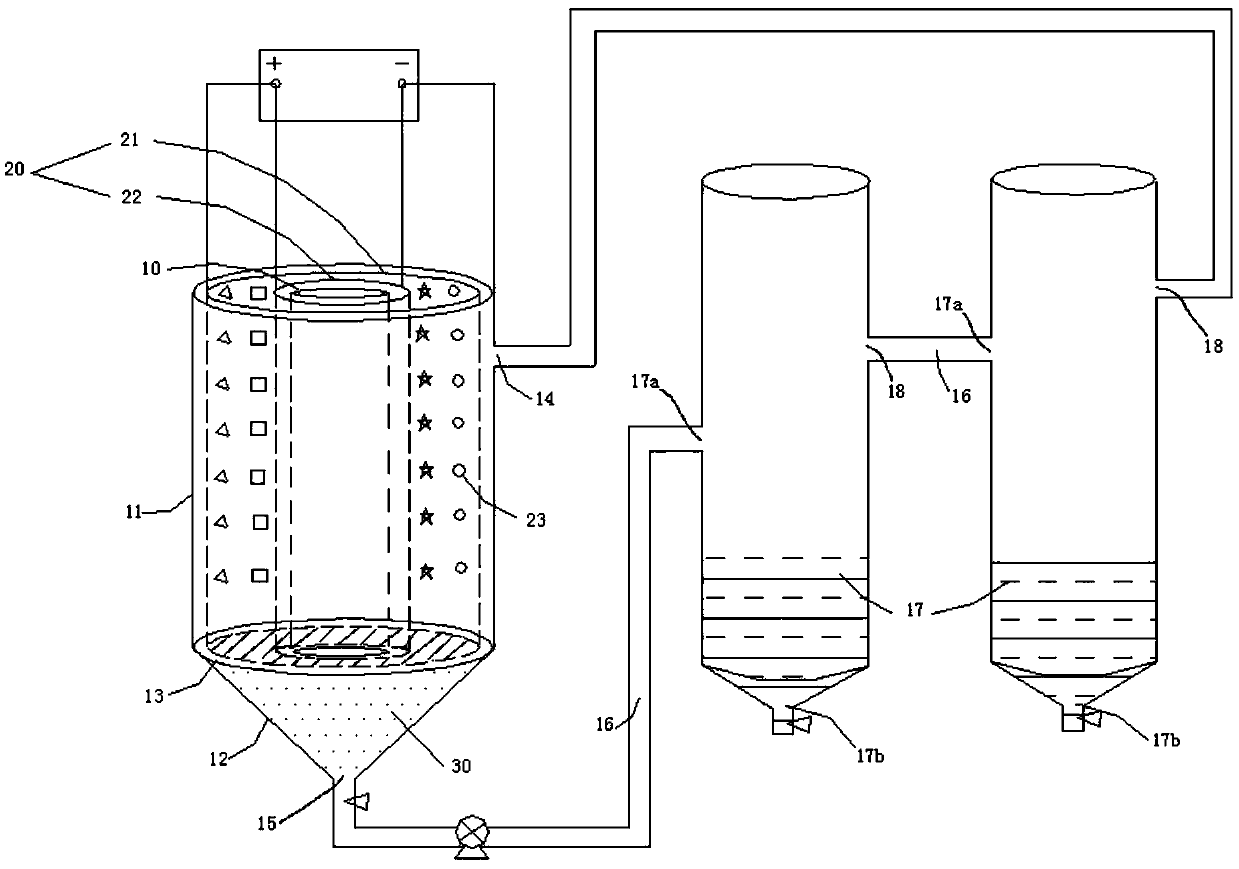

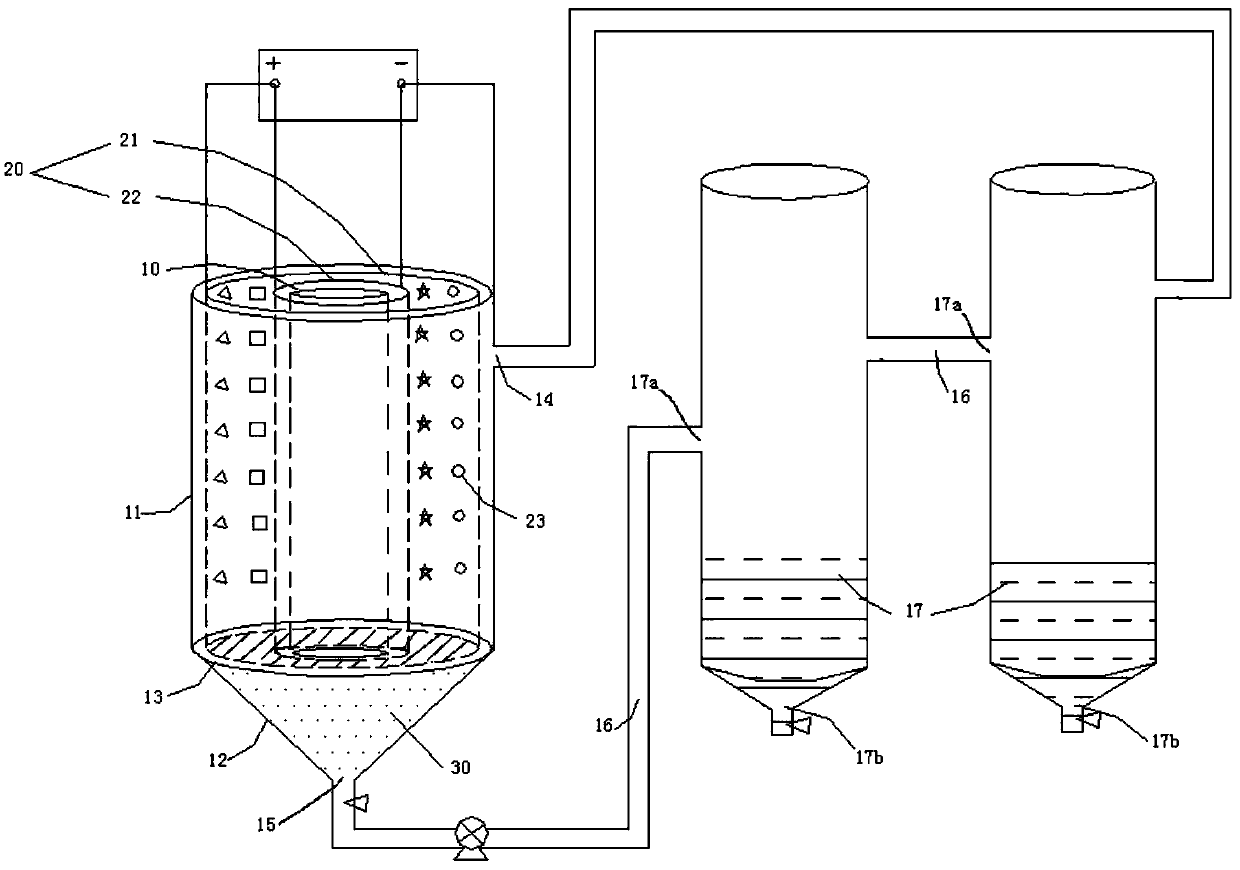

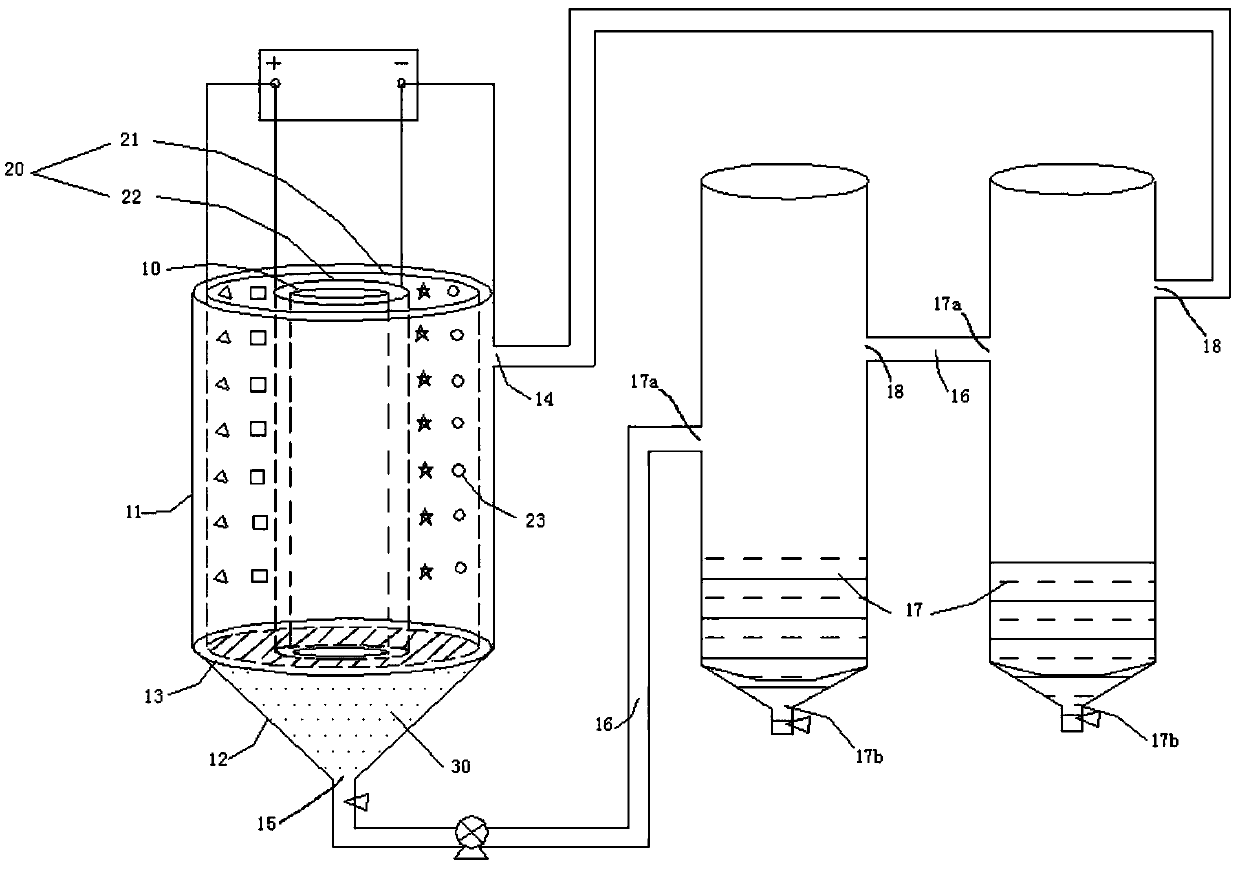

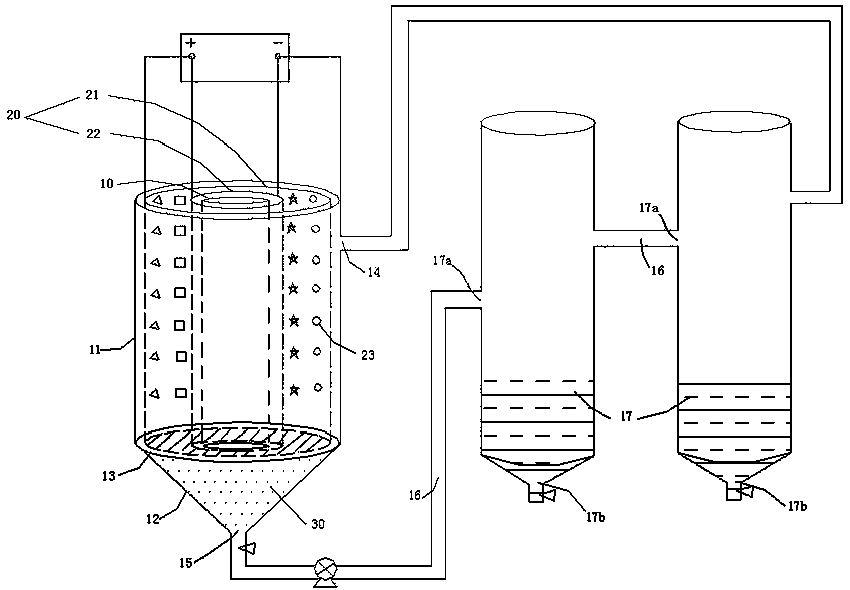

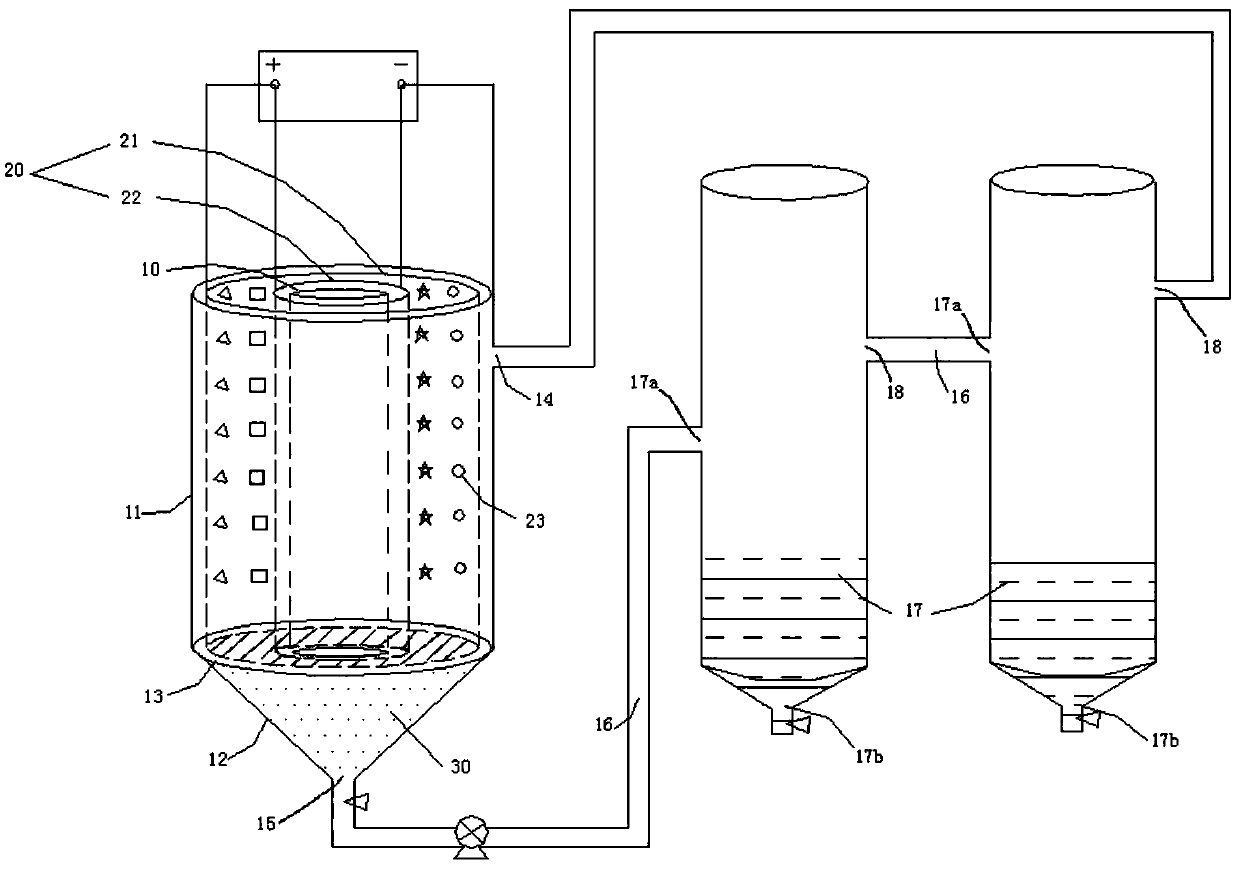

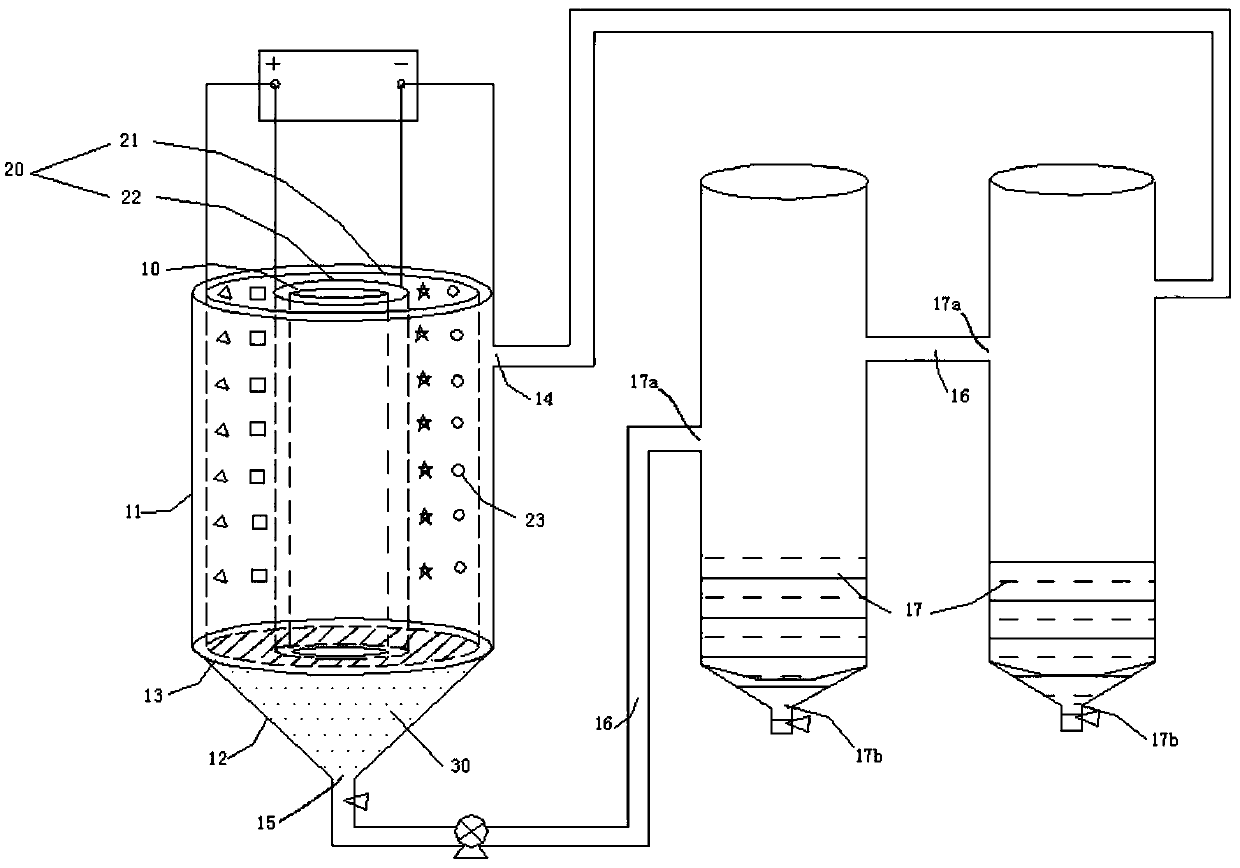

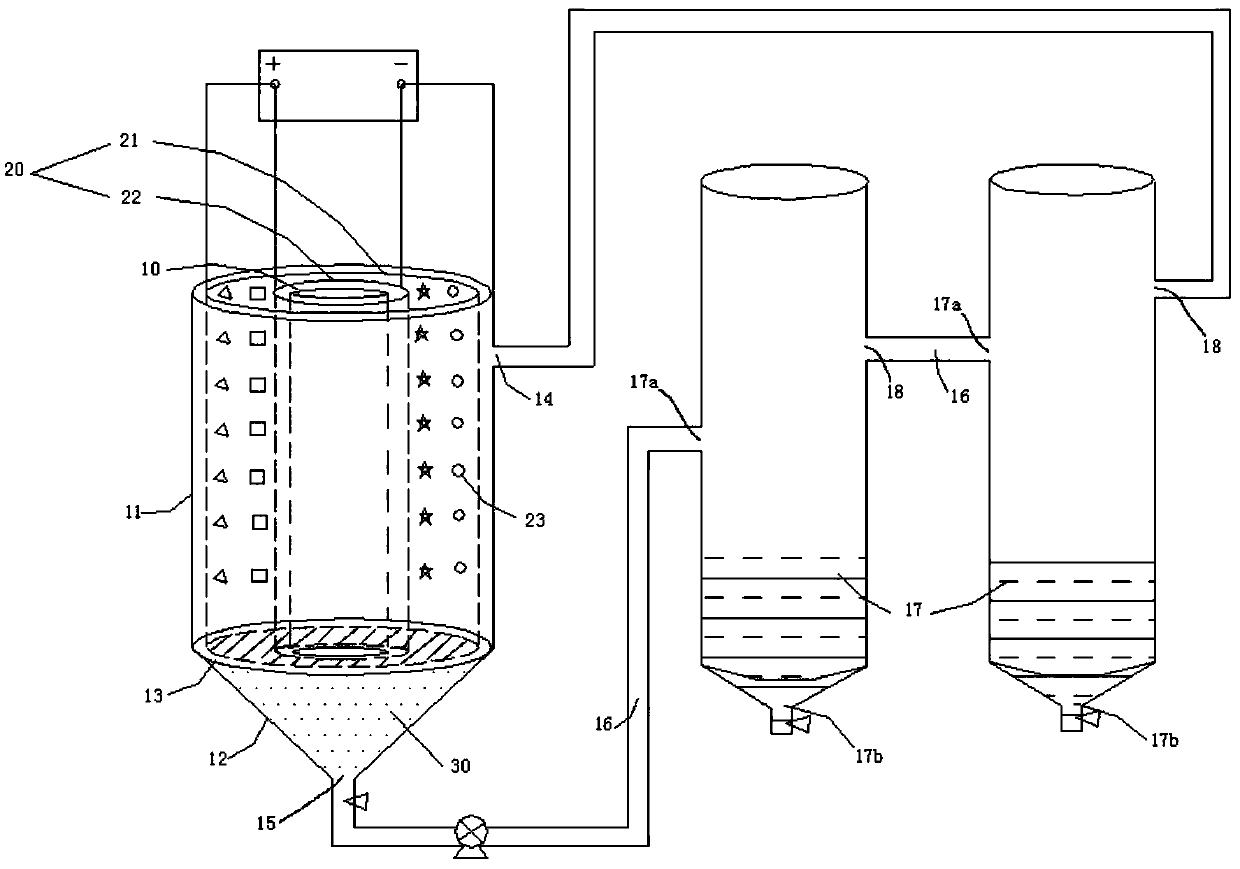

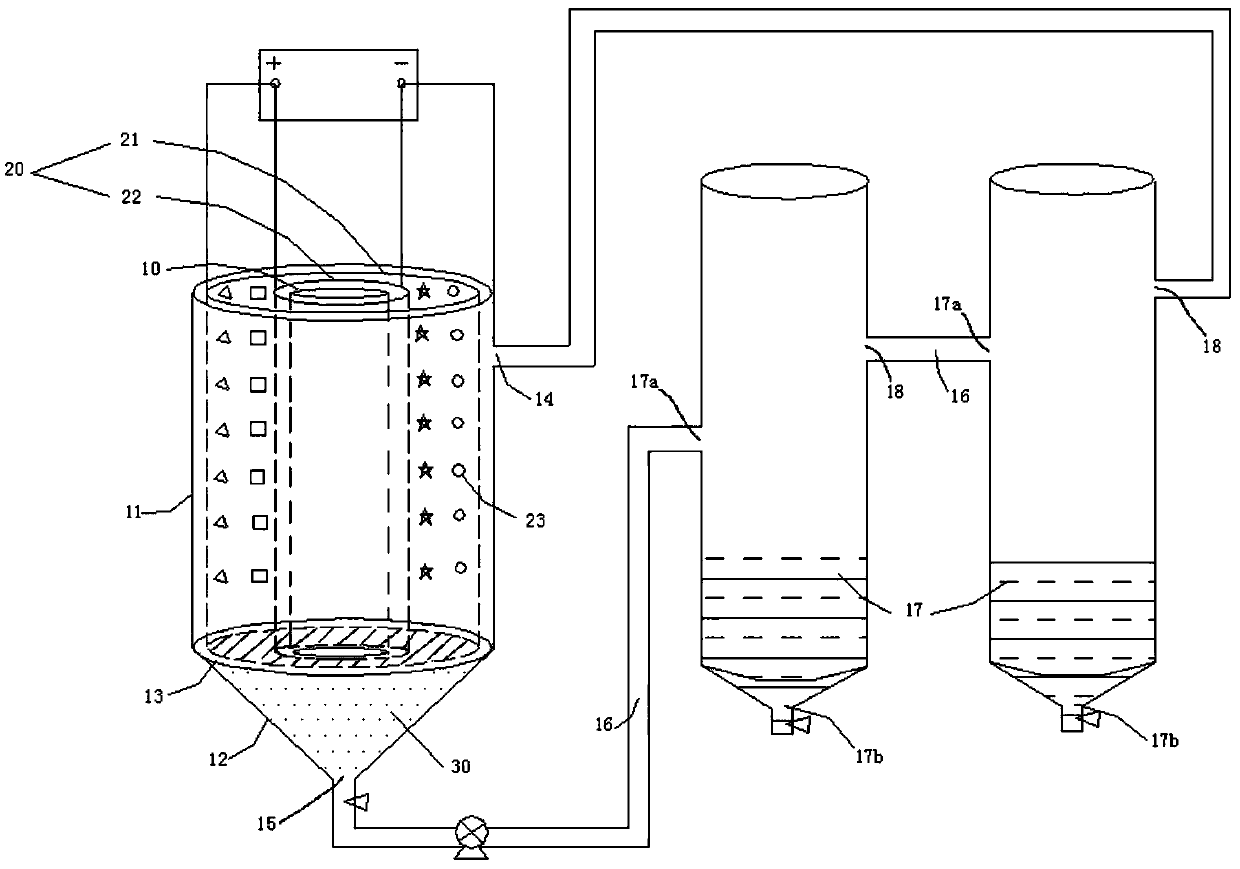

Apparatus and method for preparing high-concentration chromate solution

The invention relates to a device for preparing a high-concentration chromate solution, wherein the device comprises an electrolytic tank, a double-cathode device, a double-anode device, and a plurality of settling tanks; the electrolytic tank comprises a cylindrical main body part and a conical collection part, the upper end of the main body part is provided with an electrolyte solution inlet, and the lower end of the main body part is provided with an electrolyte solution outlet; an inner cathode is arranged in the electrolytic tank, and the cylindrical main body part of the electrolytic tank is used as an outer cathode; the double-anode device comprises a cylindrical inner anode and a cylindrical outer anode arranged outside the cylindrical inner anode in a sleeving manner, and the inner cathode is arranged inside the inner anode in a sleeving manner; an insulation partition plate is used for supporting the double-anode device; each settling tank is provided with a feed port and a discharge port, the feed port of the first settling tank is connected with a discharge port of the electrolytic tank, the discharge port of the first settling tank is connected with the feed port of the second settling tank, and in the way, the discharge port of the last settling tank communicates with the electrolytic tank.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method for preparing dichromate by utilizing ferrochrome

The invention discloses a method for preparing dichromate by using ferrochrome. The method comprises the following steps: an electrolyte solution undergoes an electrolytic reaction in a self-circulation mode, the temperature of the electrolyte solution in an electrolytic cell is automatically controlled to be 20-60 DEG C, the circulating reacting time for the electrolyte solution is controlled according to a formula 1 being t=c1*V1*M2 *Eta / (2*n*M1*I), and a high-concentration chromate solution is obtained; hydrothermal reaction is carried out on the high-concentration chromate solution to obtain a high-purity chromate solution; the high-purity chromate solution is prepared into a chromate solution with the weight percent concentration of 20%-40%, and the prepared chromate solution is mixed with a dichromate solution with the weight percent concentration of 23%-50% to prepare an anode mixed feeding liquid; and a cathode mixed feeding liquid is provided, and the electrolytic reaction is carried out on the anode mixed feeding liquid and cathode mixed feeding liquid to obtain a dichromate solution.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

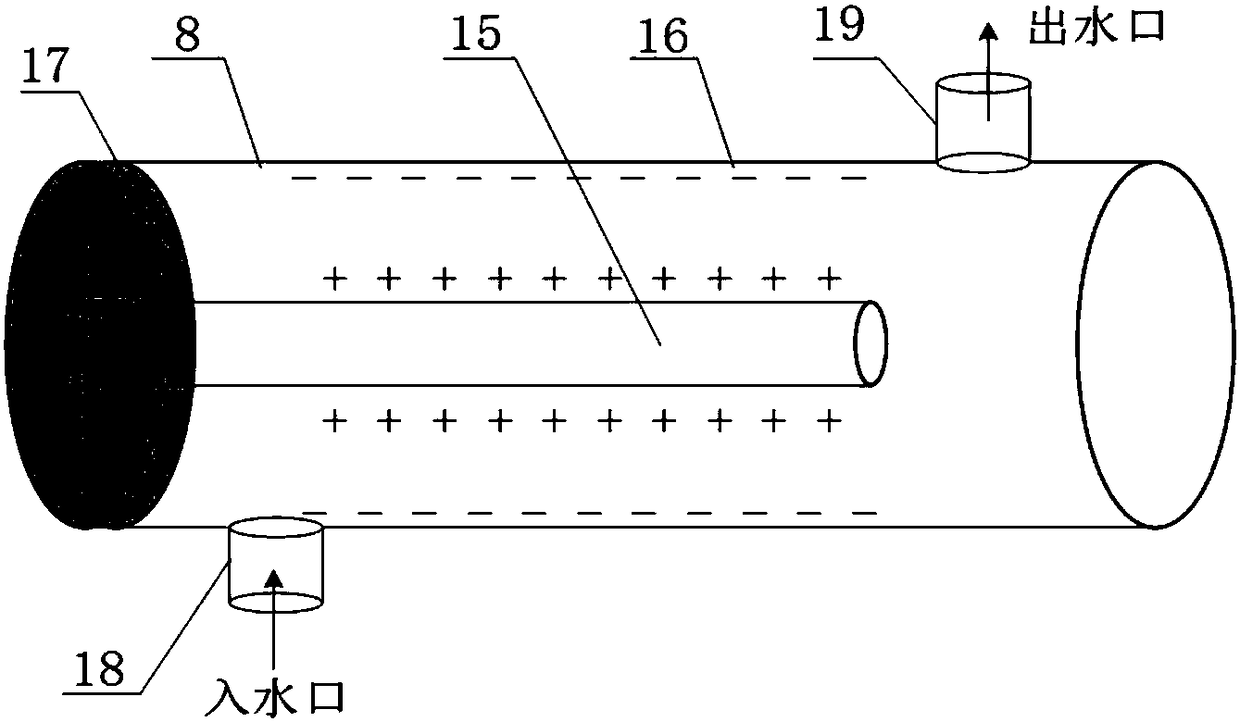

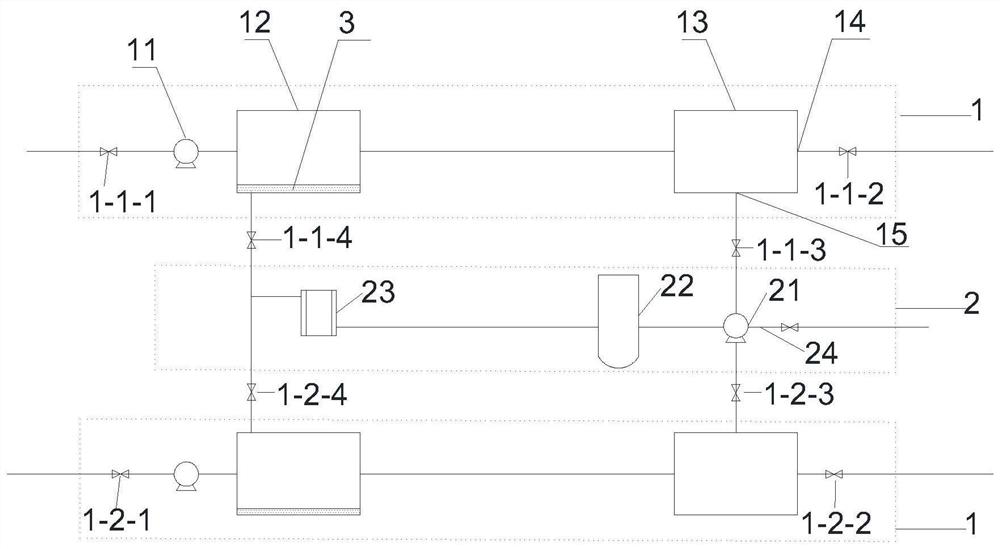

Multifunctional running water type electrolysis equipment

PendingCN109678226ASolve the problem of energy consumptionAddressing Damage to Outer Electrode PlatesWater/sewage treatmentHigh concentrationElectrolysis

The invention discloses multifunctional running water type electrolysis equipment. Miniaturization construction is realized while the larger electrolysis area is realized, besides, a low-voltage, low-current and low-energy-consumption recycling electrolysis manner is used, the service life of an external electrode plate and a treatment membrane is guaranteed, meanwhile, the treatment membrane is simple to replace, the equipment can be applied to production of high-concentration strong acid function water or high-concentration strong alkaline function water, harmless tretament of liquids, desalination tretament and the like, and the effect of one machine with multiple purposes is realized.

Owner:BEIJING JIANYUAN TIANDI ENVIRONMENTAL PROTECTION TECH

A plasma high-efficiency sewage treatment device and its treatment method

ActiveCN109534459BEfficient re-electrolysisEfficient degradationWater/sewage treatment by irradiationWater treatment multistage treatmentsElectrolysisPhysical chemistry

The invention discloses a plasma high-efficiency sewage treatment device and a treatment method thereof, comprising a reaction container, a first plasma electrode assembly, a second plasma motor assembly, an atomization assembly, a layered plate and a rectification assembly, the reaction container It is an inner cavity structure, the layered plate is horizontally placed in the inner cavity of the reaction container, and the inner cavity of the reaction container is divided into the first reaction chamber of the upper layer and the second reaction chamber of the lower layer by the layered plate, so The atomization assembly and the first plasma electrode assembly are respectively arranged above the layered plate, the rectification assembly is arranged in the second reaction chamber, the second plasma electrode assembly is arranged on the rectification assembly, and the second The aqueous solution after the electrolysis of the plasma electrode assembly can ensure the full electrolysis of the sewage solution, and rectify the sewage water flow to ensure the stability of its electrolysis effect.

Owner:扬州市博喧环保科技有限公司

Method for preparing chromium oxide green by using ferrochrome

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Particle electrode sewage treatment equipment and sewage treatment method using same

PendingCN112340900AContinuous processingImprove processing efficiencySpecific water treatment objectivesTreatment involving filtrationOxygen tankFiltration

The invention relates to particle electrode sewage treatment equipment, comprising two particle electrode adsorption and filtration systems and an adsorbent regeneration system, wherein each particleelectrode adsorption and filtration system comprises a water inlet pump, a particle electrode adsorption tank and a filtration device which sequentially communicate with each other through a pipeline,a particle electrode is arranged in each particle electrode adsorption tank, and a treated water outlet and a particle electrode outlet are formed in the filtering device; and the adsorbent regeneration system comprises a pressure water pump, a dissolved oxygen tank and a three-dimensional electrolytic cell which sequentially communicate with each other through a pipeline, a feeding port of the pressure water pump communicates with the two particle electrode outlets through pipelines, the feeding port of the pressure water pump is connected with an oxygen inlet pipe at the same time, a discharge port of the three-dimensional electrolytic cell communicates with the two ion electrode adsorption tanks through pipelines respectively, and valves are arranged on the communicating pipelines. When the particle electrode sewage treatment equipment is used for treating sewage, the number of hydroxyl radicals is increased, space distance between the particle electrodes and pollutants is shortened, the two particle electrode adsorption and filtration systems conduct adsorption alternately, and sewage treatment efficiency is improved.

Owner:中机高科(重庆)环保工程有限公司

Method for preparing iron oxide red by using ferrochrome

The invention relates to a method for preparing iron oxide red by using ferrochromium, wherein the method comprises the following steps: a first step, providing a preparation device including an electrolytic tank, a double-anode device, a double-cathode device, an insulating partition plate, a plurality of settling tanks and an electrode; a second step, carrying out an electrolytic reaction by a self circulating mode, automatically controlling the temperature at 20 DEG C-60 DEG C, and controlling the electrolyte solution circulating reaction time according to the formula 1 described in the specification, to obtain a high-concentration chromate solution and a solid slag material; a third step, carrying out conventional gravity magnetic sorting of the solid slag material obtained in the second step, and removing inclusion small-particle ferrochromium to obtain iron hydroxide with the particle size of 30 [mu]m-74 [mu]m; and a fourth step, calcining the iron hydroxide with the particle size of 30 [mu]m-74 [mu]m at the temperature of 500 DEG C-800 DEG C for about 1 h-4 h to obtain iron oxide red.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Device and method for preparing high-concentration chromate solution

The invention relates to a device for preparing a high-concentration chromate solution, wherein the device comprises an electrolytic tank, a double-cathode device, a double-anode device, and a plurality of settling tanks; the electrolytic tank comprises a cylindrical main body part and a conical collection part, the upper end of the main body part is provided with an electrolyte solution inlet, and the lower end of the main body part is provided with an electrolyte solution outlet; an inner cathode is arranged in the electrolytic tank, and the cylindrical main body part of the electrolytic tank is used as an outer cathode; the double-anode device comprises a cylindrical inner anode and a cylindrical outer anode arranged outside the cylindrical inner anode in a sleeving manner, and the inner cathode is arranged inside the inner anode in a sleeving manner; an insulation partition plate is used for supporting the double-anode device; each settling tank is provided with a feed port and a discharge port, the feed port of the first settling tank is connected with a discharge port of the electrolytic tank, the discharge port of the first settling tank is connected with the feed port of the second settling tank, and in the way, the discharge port of the last settling tank communicates with the electrolytic tank.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Electrolytic appts. and electrolytic treatment method

ActiveCN1263895CIncrease current densityIncrease the electrolysis areaCellsPhotography auxillary processesEngineeringHeat generation

To maintain compactibility, and to improve electrolytic efficiency while suppressing heat generation. A hollow electrode 21 in which many bore holes 23 are formed on the circumferential wall is arranged at the inside of a vertical, cylindrical treatment tank 10 in a state where an annular flow passage 18 is secured between the hollow electrode 21 and the inner wall of the treatment tank 10, and a rod-shaped electrode 22 is cocentrically arranged at the inside thereof. The circumferential wall 12 of the treatment tank 10 is provided with an introduction port 13 for introducing the liquid to be treated from the outside of the treatment tank 10 into the lower end of the hollow electrode 21, and an introduction-out port 14 for introducing-out the liquid to be treated flowed out from each bore hole 23 inside the treatment tank 10 at the upper end side of the hollow electrode 21 to the outside of the treatment tank 10.

Owner:DOWA METALS & MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com