Multifunctional running water type electrolysis equipment

A technology of flowing water electrolysis cell and electrolysis equipment, which is applied in the field of multifunctional flowing water electrolysis equipment, can solve the problems of increased cost of consumables, high energy consumption of outer electrode plates, difficult water discharge, etc., and achieves extended service life, low current and voltage, Effect of preventing excess current and voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

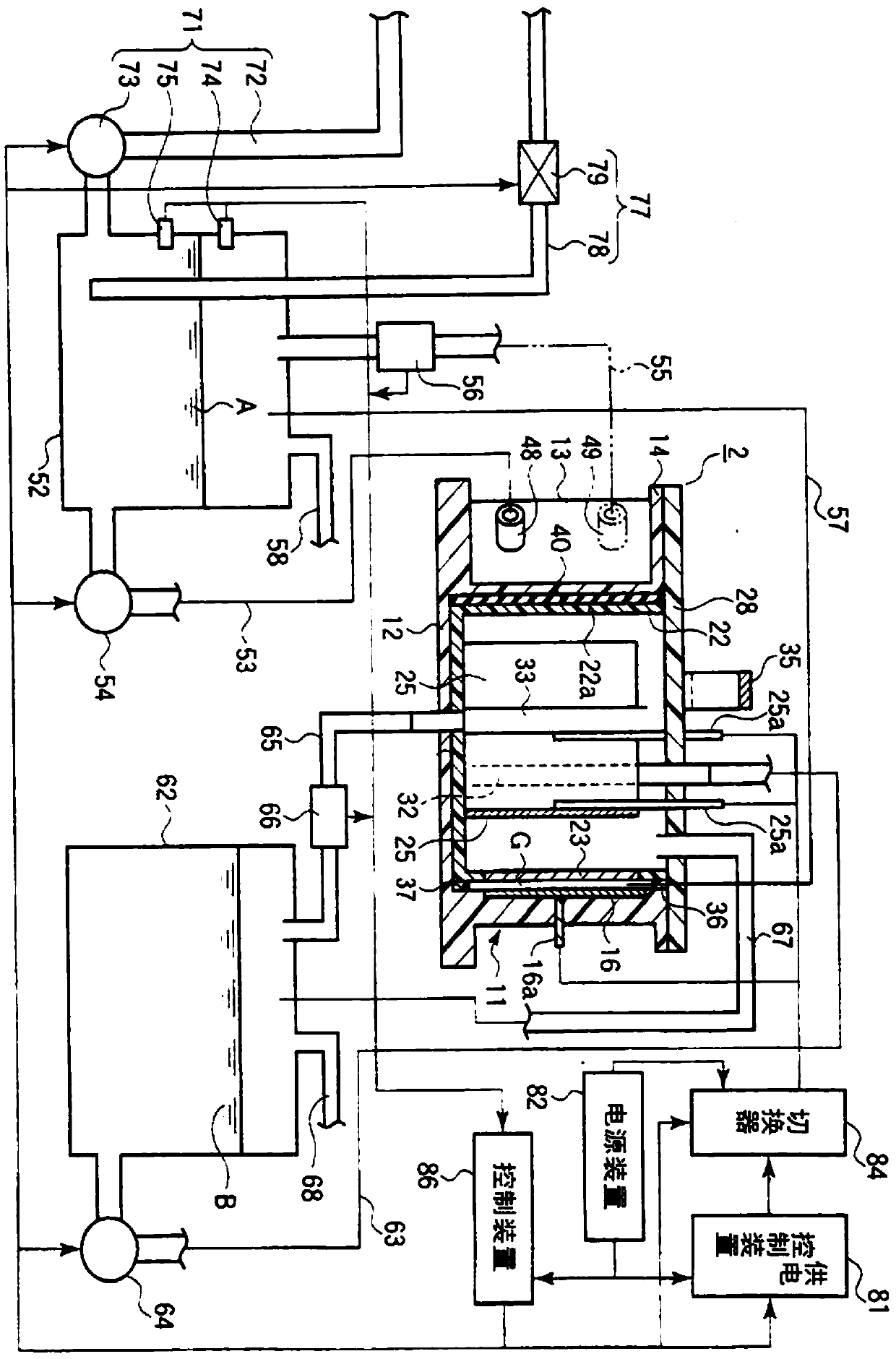

[0127] The working principle of the present invention is as follows:

[0128] First start the control device 86, and the control device 86 starts the second pump 64 of the electrolyte liquid supply device, and transports the second liquid B containing the electrolyte in the electrolyte liquid storage tank 62 to the multi-faceted inner tank 22 of the multifunctional flow-through electrolytic cell 2 When the second liquid B containing electrolyte injected into the multi-plane inner tank 22 exceeds the upper end of the liquid level control pipe 33, the second liquid B containing electrolyte that exceeds the liquid level in the liquid level control pipe 33 will flow through the second return pipe 65. Back in the electrolyte solution storage tank 62.

[0129] The predetermined liquid level of the second liquid B containing the electrolyte is set by the liquid level control pipe 33, and the second liquid B containing the electrolyte continues to circulate until the second pump 64 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com