Electrolytic appts. and electrolytic treatment method

An electrolysis device and electrolysis treatment technology, applied in the electrolysis process, electrolysis components, electrode shapes/types, etc., can solve the problems of low electrolysis efficiency, low fluidity and agitation, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

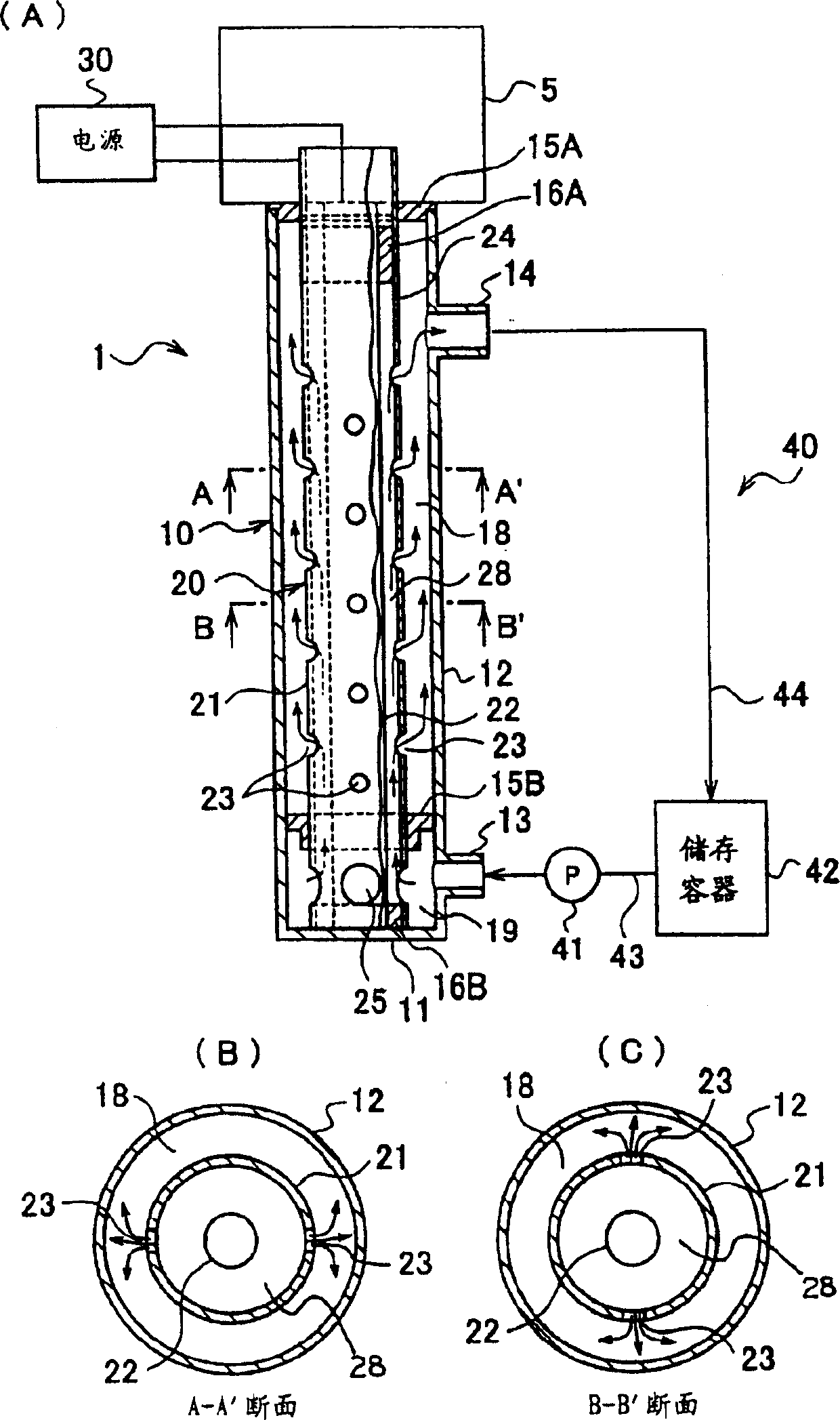

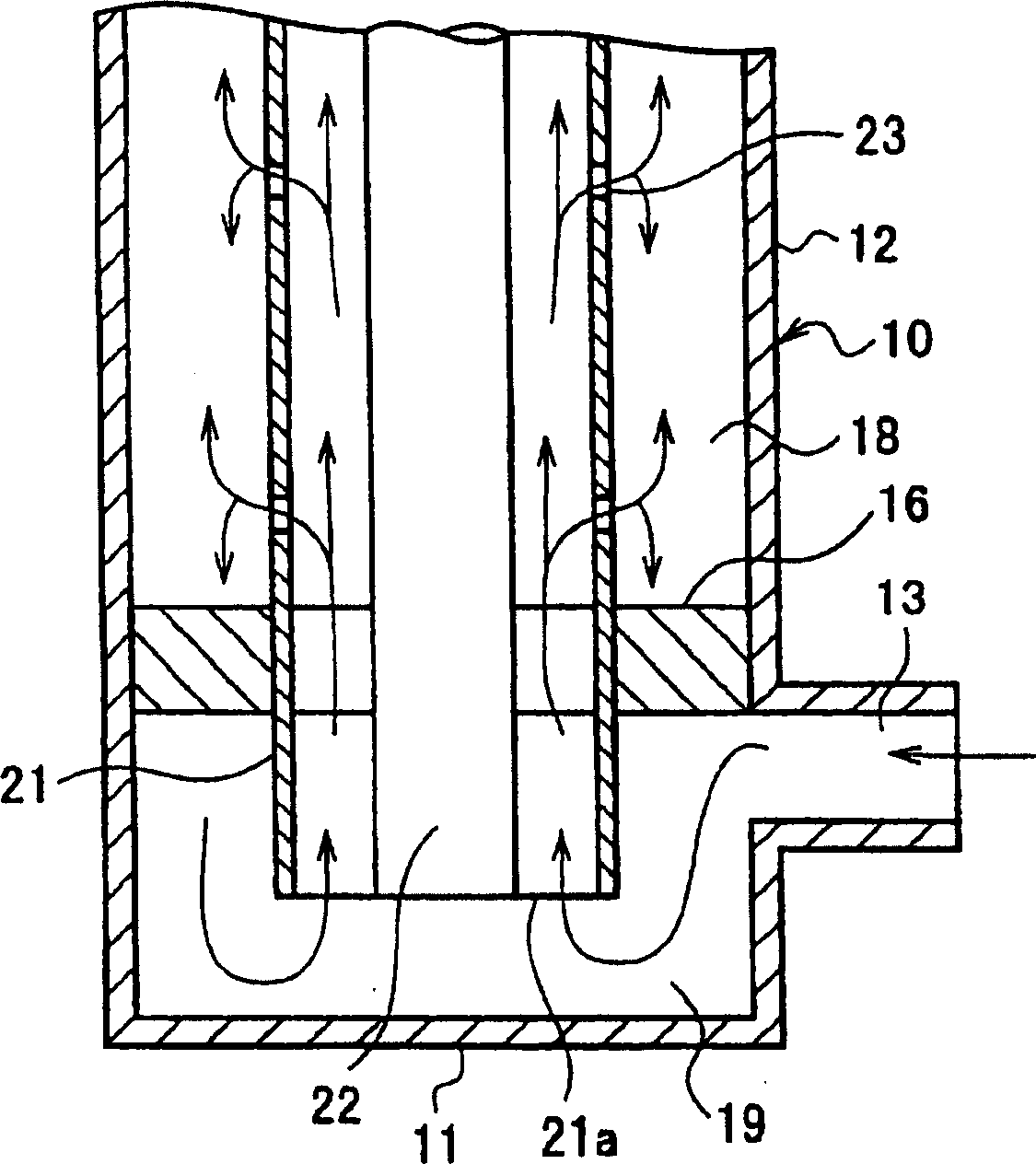

[0080] (Electrolysis Apparatus) The electrolysis apparatus shown in Fig. 1 was used. The hollow electrode as the first electrode is made of φ50×4001 stainless steel, and the rod-shaped electrode as the second electrode is made of φ30×4001 iron. On the peripheral wall of the hollow electrode, as shown in FIG. 1 , 20 through-holes of φ10 are provided at intervals in the vertical direction and at approximately equal intervals in the left-right direction.

[0081] (Solution to be treated) A gold plating solution containing 0.98 g / l of gold was used as the liquid to be treated.

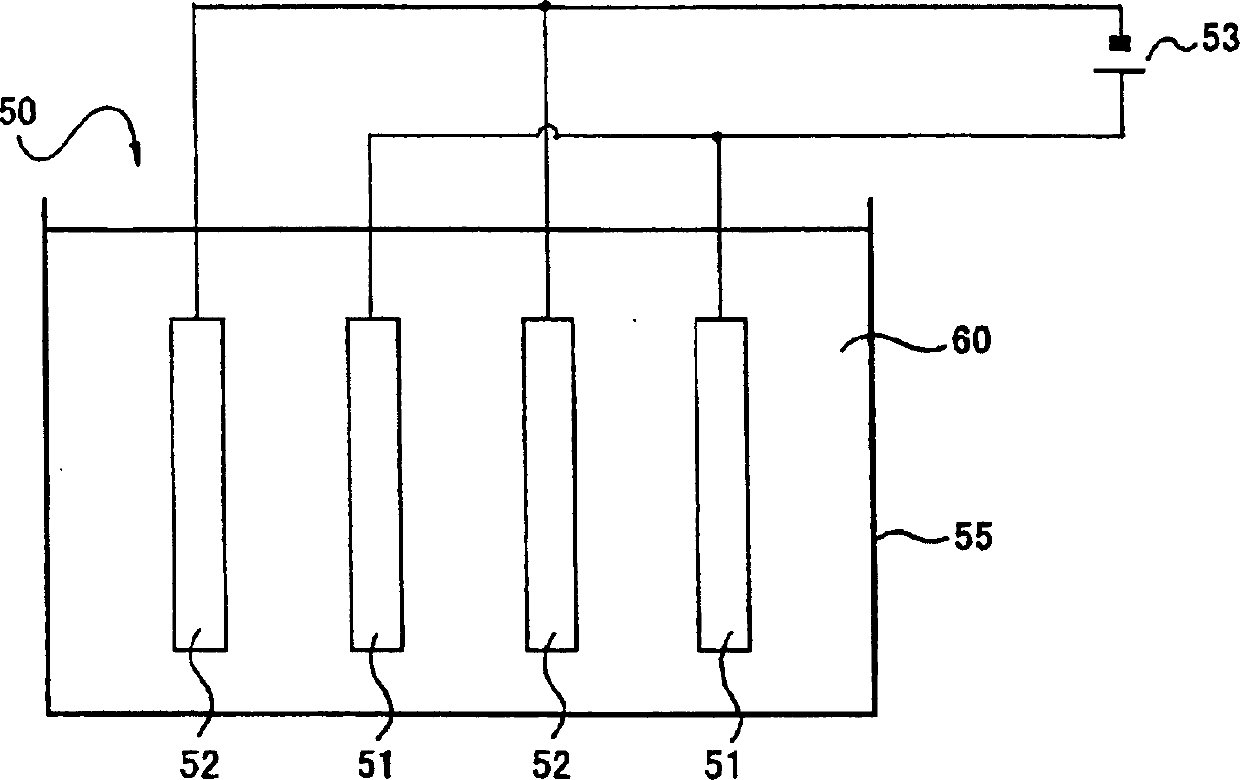

[0082] (Electrolysis conditions) As shown in FIG. 4 , voltage and current were supplied to the electrodes, and the gold concentration in the liquid to be treated was measured at regular intervals.

[0083] (Electrolysis Results) The electrolytic extraction rate of gold was 2A·hr / g.

Embodiment 2

[0085] (Electrolysis device) The same electrolysis device as in Example 1 was used.

[0086] (Solution to be treated) A thin gold plating solution containing 0.91 g / l of gold was used as the liquid to be treated.

[0087] (Electrolysis conditions) As shown in FIG. 5 , voltage and current were supplied to the electrodes, and the gold concentration in the liquid to be treated was measured at regular intervals.

[0088] (Results of Electrolysis) The electrolytic extraction rate of gold was 6A·hr / g.

Embodiment 3

[0090] (Electrolysis device) The same electrolysis device as in Example 1 was used.

[0091] (Solution to be treated) A thin gold plating solution containing 0.67 g / l of gold was used as the liquid to be treated.

[0092] (Electrolysis conditions) As shown in FIG. 6, voltage and current were supplied to the electrodes, and the gold concentration in the liquid to be treated was measured at regular intervals.

[0093] (Electrolysis Results) The electrolytic extraction rate of gold was 10A·hr / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com