Method for preparing chromium oxide green by using ferrochrome

A technology of chromium oxide green and ferrochrome, which is applied in the direction of electrolysis components and electrolysis process, can solve the problems of cumbersome process, land occupation, environmental pollution, etc., and achieve the effect of simplifying process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

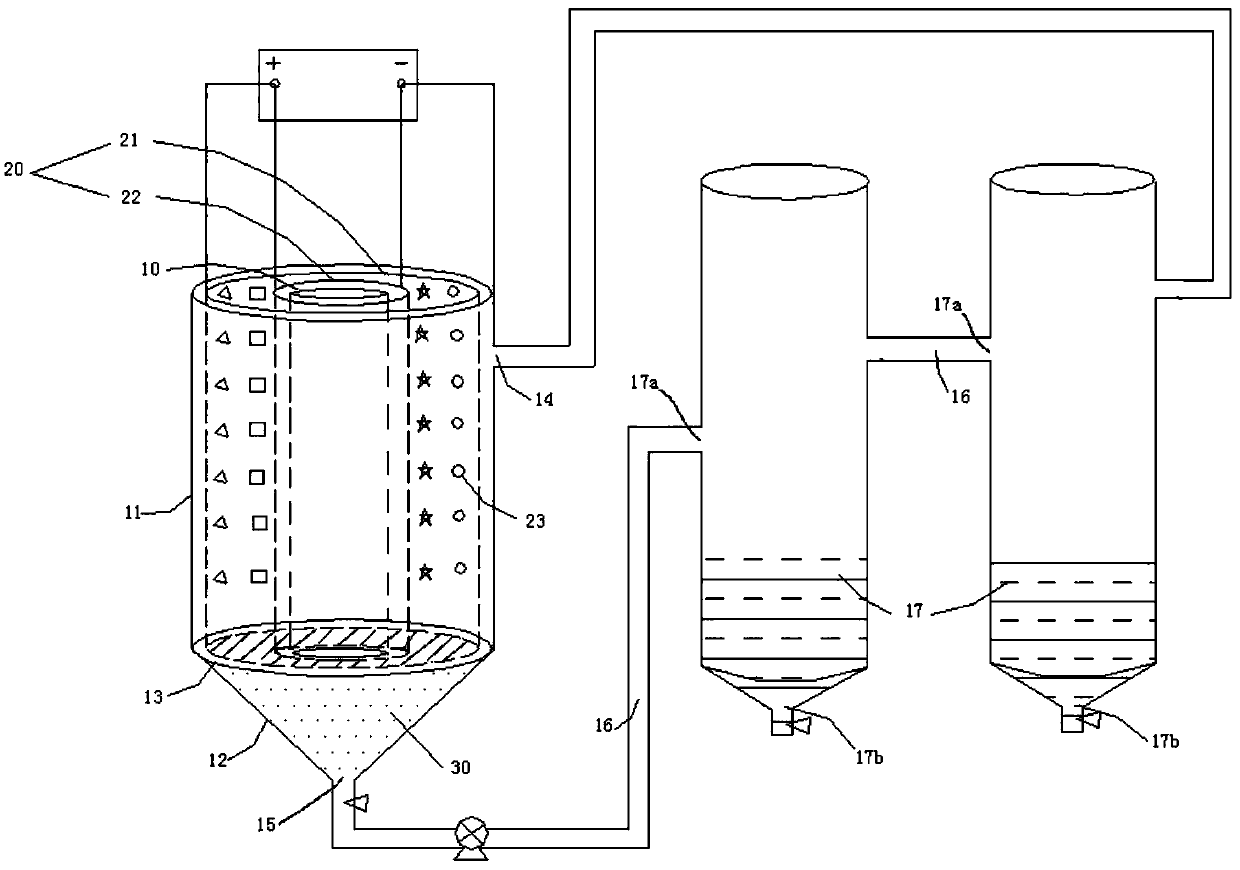

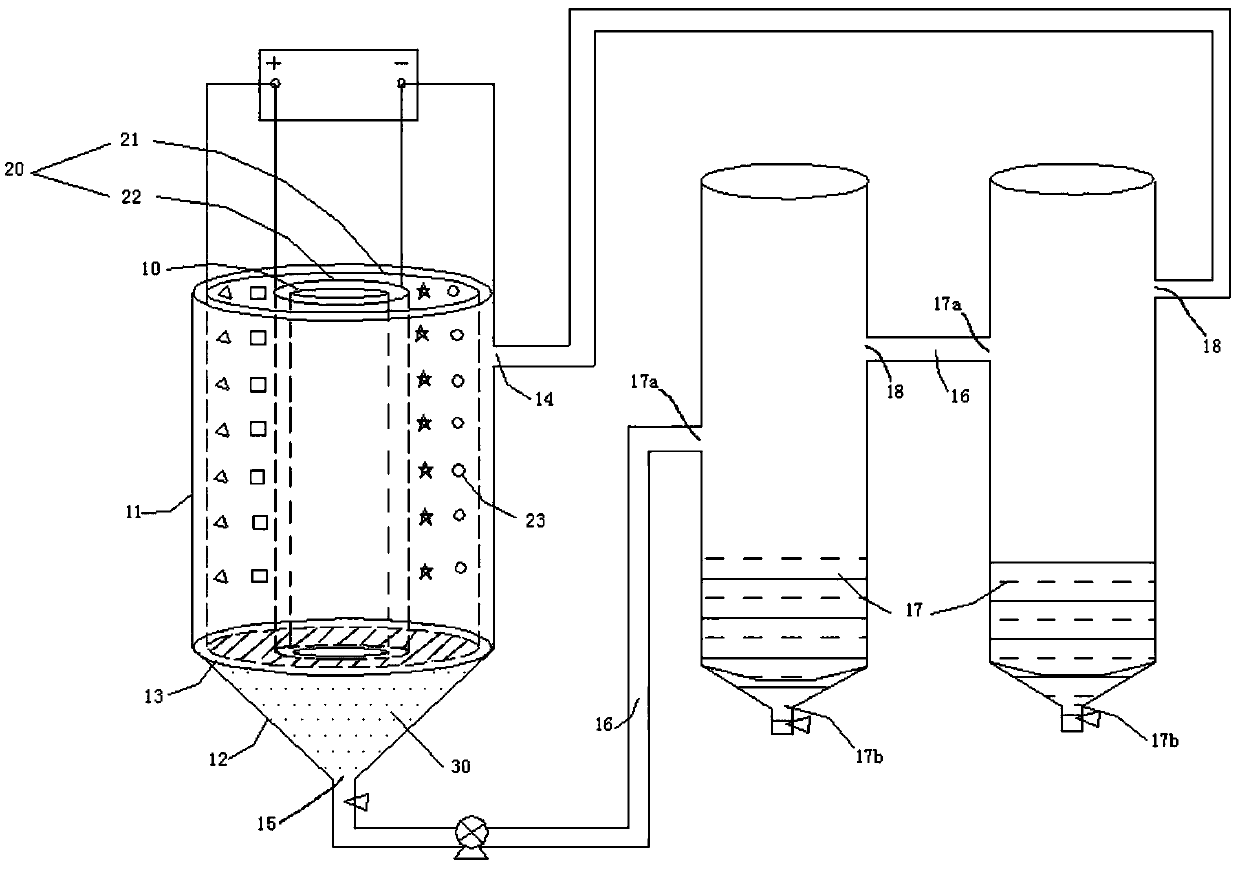

Method used

Image

Examples

Embodiment 1

[0089] Example 1: High-concentration ammonium chromate solution was prepared by electrolysis using ferrochromium and ammonia water as raw materials.

[0090] Take 445g of high-carbon ferrochrome and 760mL of 210g / L ammonia water, and place them in the electrolytic cell. Direct current 2A, electrolysis 22h. Obtained 557mL electrolyte and 11.4g ferric hydroxide precipitate. The electrolytic solution contains 21g of ammonium chromate. After evaporation and crystallization, 9.5 g of ammonium chromate solid was obtained, and the ammonium chromate solid was calcined at 1000° C. for 2 hours to obtain 6.1 g of dichromium trioxide.

Embodiment 2

[0092]Take 450g of high-carbon ferrochromium and 800mL of 140g / L ammonia water, and place them in the electrolytic cell. Connect direct current 1.6A, electrolysis 11h. Obtain 630mL electrolyte and 3.1g ferric hydroxide precipitate. The electrolytic solution contains 9.9 g of ammonium chromate. After evaporating and crystallizing, 4.7 g of ammonium chromate solid was obtained, and the ammonium chromate solid was calcined at 1050° C. for 6 hours to obtain 3.0 g of dichromium trioxide.

Embodiment 3

[0093] Implementation example 3: Get 449g of high-carbon ferrochromium, 800mL of 42g / L ammoniacal liquor, place in electrolyzer. Connect direct current 1.8A, electrolysis 11h. Obtained 685mL electrolyte and 4.2g ferric hydroxide precipitate. The electrolytic solution contains 9.4 g of ammonium chromate. After evaporative crystallization, 4.3 g of ammonium chromate solid was obtained, and the ammonium chromate solid was calcined at 950° C. for 12 hours to obtain 2.9 g of dichromium trioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com