Spherical porous filler and electrolytic oxidation system for treating organic matters in heavy salt water

A porous filler and high brine technology, applied in the field of electrolytic oxidation system, can solve the problems that the biological treatment method cannot run for a long time, the biological reaction device is difficult to operate stably, and the growth of microorganisms is contained, so as to promote the efficiency of ozone oxidation and improve the efficiency of ozone catalytic oxidation , Efficient and rapid degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

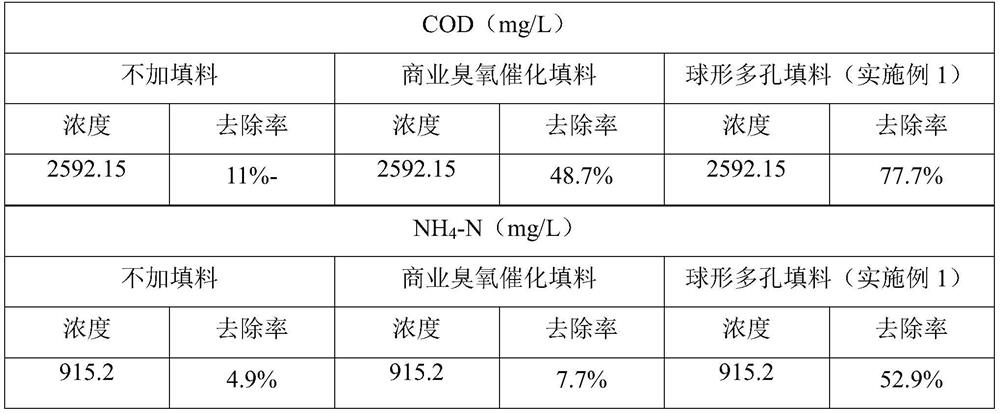

Embodiment 1

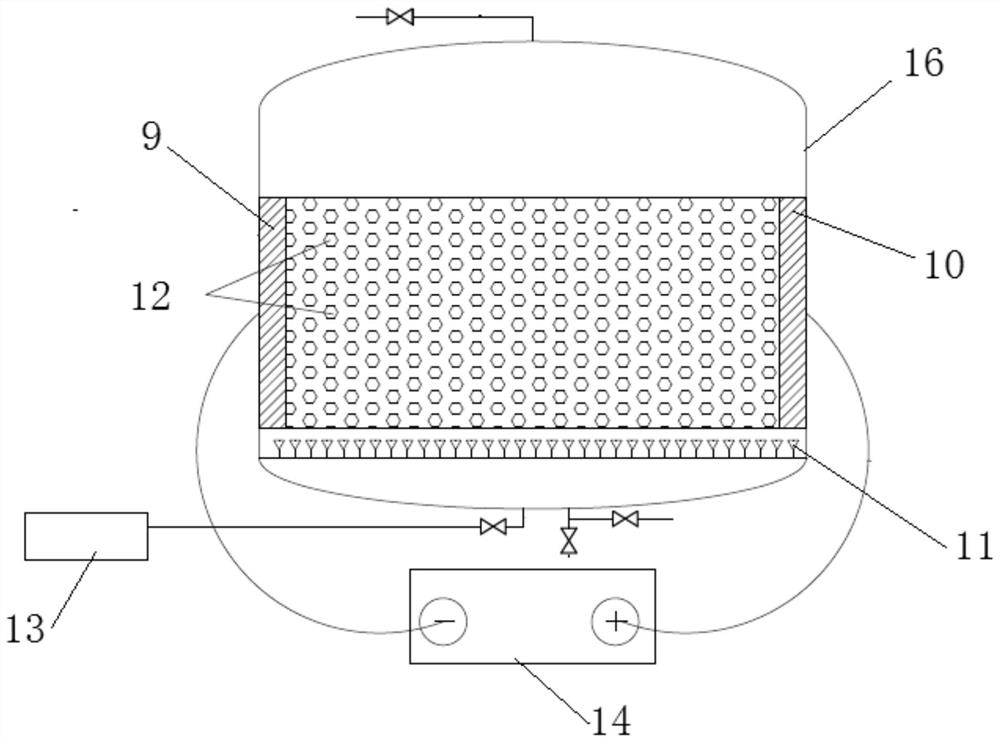

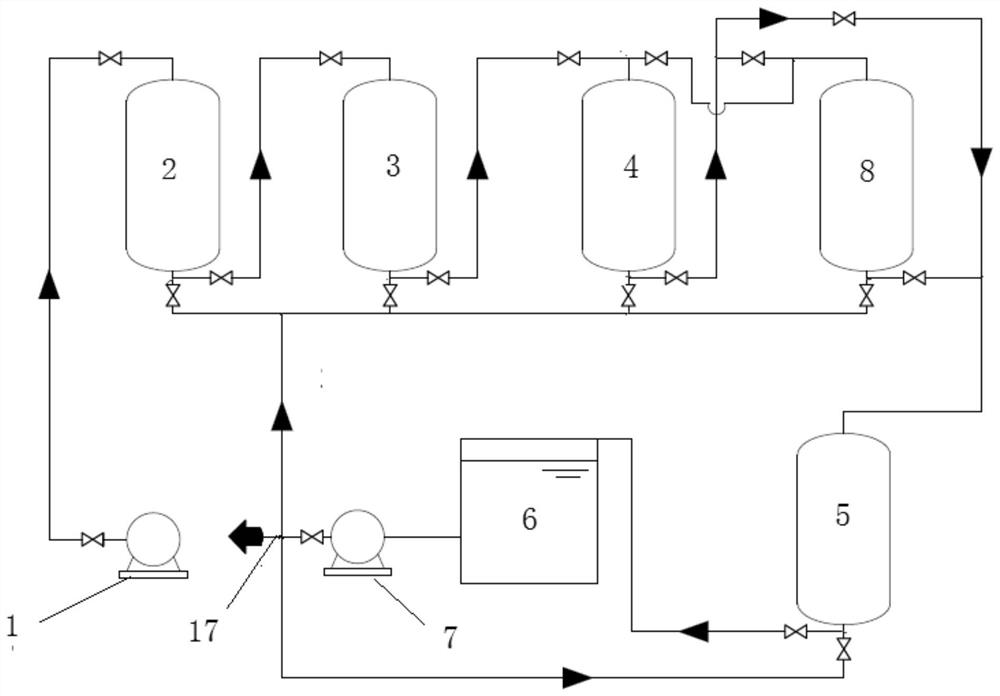

[0026] A kind of spherical porous filler is made by following method:

[0027] Clean the blast furnace dust, dry it, grind it with a ball mill, mix the ground blast furnace dust with clay at a mass ratio of 1:1.3, add deionized water and mix evenly, and then use a granulator to granulate; Under nitrogen protection, sinter at 950° C. for 43 minutes, and cool to room temperature to obtain spherical porous fillers.

[0028] The average particle diameter of the spherical porous filler is 5 mm.

Embodiment 2

[0030] A kind of spherical porous filler is made by following method:

[0031] Clean the blast furnace dust, dry it, grind it with a ball mill, mix the ground blast furnace dust and clay in a mass ratio of 1:1, add deionized water to mix evenly, and then use a granulator to granulate; Under nitrogen protection, sinter at 900° C. for 45 minutes, and cool to room temperature to obtain spherical porous fillers.

[0032] The average particle diameter of the spherical porous filler is 5 mm.

Embodiment 3

[0034] A kind of spherical porous filler is made by following method:

[0035] Clean the blast furnace dust, dry it, grind it with a ball mill, mix the ground blast furnace dust and clay in a mass ratio of 1:1.5, add deionized water and mix evenly, and then use a granulator to granulate; Under nitrogen protection, sinter at 1000° C. for 40 minutes, and cool to room temperature to obtain spherical porous fillers.

[0036] The average particle diameter of the spherical porous filler is 5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com