Utilize ferrochromium to prepare the method for chromic anhydride

A technology of chromic anhydride and ferrochrome, applied in the field of development and utilization of chromite ore, to achieve the effect of simplifying process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

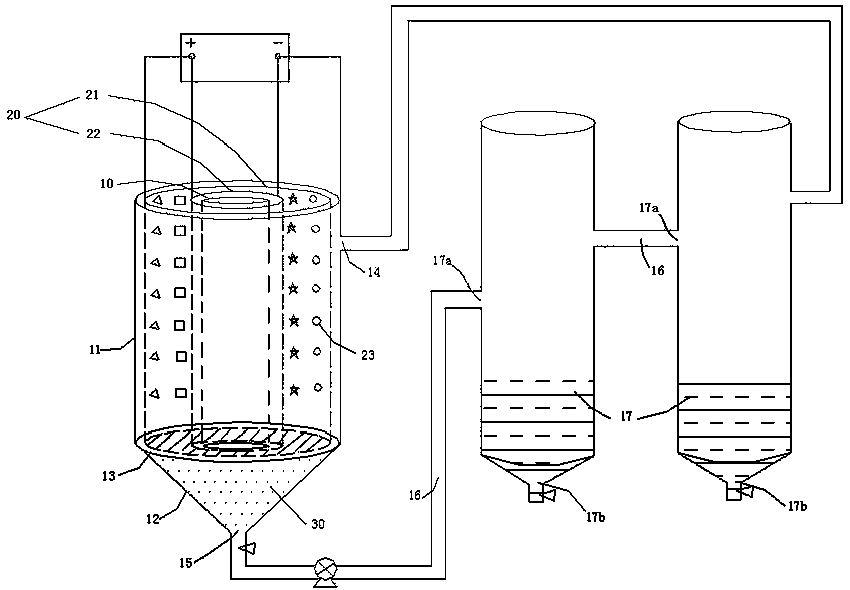

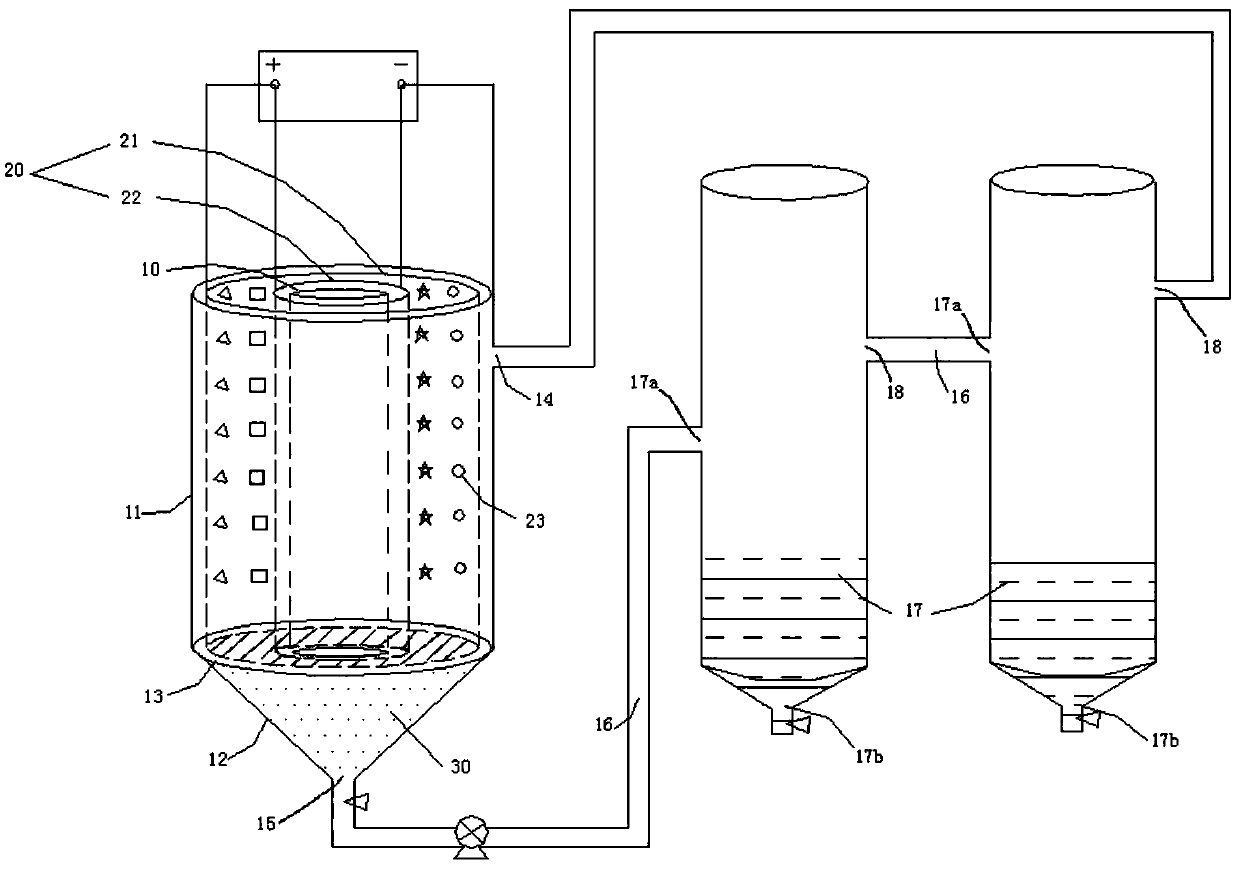

Image

Examples

Embodiment 1

[0089] The sodium chromate solution obtained by the electrolysis method is passed through an ion membrane electrolysis device to obtain a sodium dichromate solution. Take 28.54 kg of sodium dichromate solution, adjust its concentration to a sodium dichromate content of 27% (calculated as sodium dichromate dihydrate, the same below), and the atomic ratio of sodium to chromium is 1:1. Then send to the first-stage anode chamber of the four-stage serial ion-exchange membrane electrolyzer, and the cathode chamber is fed with a concentration of 30% sodium hydroxide solution. Control the circulation flow rate of the anode chamber and the cathode chamber at 680 mL / min, the feed flow rate of the anode chamber at 2.03 mL / min, and the current density at 2 kA / m 2 , the reaction temperature was 75.5 ℃, the voltage was 4.58 V, and the reaction was carried out for 170 h. Obtaining 25.33kg sodium dichromate content is 29.9%, and the sodium chromate atomic ratio is the sodium dichromate+chrom...

Embodiment 2

[0091] The sodium chromate solution obtained by the electrolysis method is passed through an ion membrane electrolysis device to obtain a sodium dichromate solution. Take 1.07 kg of sodium dichromate solution, adjust its concentration to 73% sodium dichromate content (calculated as sodium dichromate dihydrate), and the atomic ratio of sodium to chromium is 1:1. Then send to the anode chamber of the ion-exchange membrane electrolyzer, and the cathode chamber leads into the sodium hydroxide solution that concentration is 30%. Control the circulation flow rate of the anode chamber and the cathode chamber at 1020 mL / min, and the current density at 2.88 kA / m 2 , the reaction temperature was 74.9 ℃, the voltage was 2.89 V, and the reaction was carried out for 7 h. Obtaining 0.90 kg dihydrate sodium dichromate content is 83%, and the sodium chromate atomic ratio is 0.35 sodium dichromate+chromic acid mixed solution. The solution was evaporated and crystallized at 105 °C, aged for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com