Cerium-doped iron oxyhydroxide modified titanium foam material, preparation method thereof, and application in water treatment

A technology of foamed titanium and iron oxide, which is applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problem that iron oxyhydroxide is not effectively fixed, achieve good reusability, improve activity, Effect of improving adsorption and oxidation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

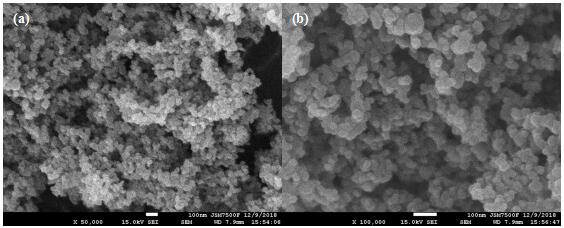

Image

Examples

Embodiment 1

[0031] A preparation method for modifying titanium foam material doped with cerium-doped iron oxyhydroxide, comprising the following steps:

[0032] A three-electrode system is formed by using titanium foam as the working electrode, platinum as the counter electrode, and a saturated calomel electrode as the reference electrode. The aqueous solution containing ferric chloride, cerium chloride, sodium sulfate, polyvinylpyrrolidone and hydrogen peroxide Electrolyte, using cyclic voltammetry from -0.85±0.05 V to 0.5±0.05V vs. SCE potential range, sweeping 20 times at a sweep rate of 150 mV / s, then taking out the working electrode and washing it with deionized water for 3 The second time, dry it with nitrogen to get the foamed titanium material doped with cerium-doped iron oxyhydroxide, denoted as (Ce-Fe)O x h y / Ti; Among them, the molar concentrations of ferric chloride, cerium chloride, sodium sulfate and hydrogen peroxide in the electrolyte are 7.5 mmol / L, 1.5 mmol / L, 0.15 mol...

Embodiment 2

[0034] A method for preparing foamed titanium material doped with cerium-doped iron oxyhydroxide, prepared according to the method of Example 1, the difference is only in changing the electrolyte, that is: the concentration of ferric chloride, cerium chloride, sodium sulfate and hydrogen peroxide in the electrolyte The molar concentrations were 8 mmol / L, 1 mmol / L, 0.15 mol / L, and 0.9 mol / L, respectively, and the mass fraction of polyvinylpyrrolidone was 2%.

Embodiment 3

[0036] A method for preparing foamed titanium material doped with cerium-doped iron oxyhydroxide, prepared according to the method of Example 1, the difference is only in changing the electrolyte, that is: the concentration of ferric chloride, cerium chloride, sodium sulfate and hydrogen peroxide in the electrolyte The molar concentrations were 10 mmol / L, 1 mmol / L, 0.15 mol / L, and 1.1 mol / L, respectively, and the mass fraction of polyvinylpyrrolidone was 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com