Component for rock breaking system

A component and rock-breaking technology, applied in the direction of borehole/well components, driving device for rotary combined drilling, drilling equipment and methods, etc., can solve problems such as interference of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

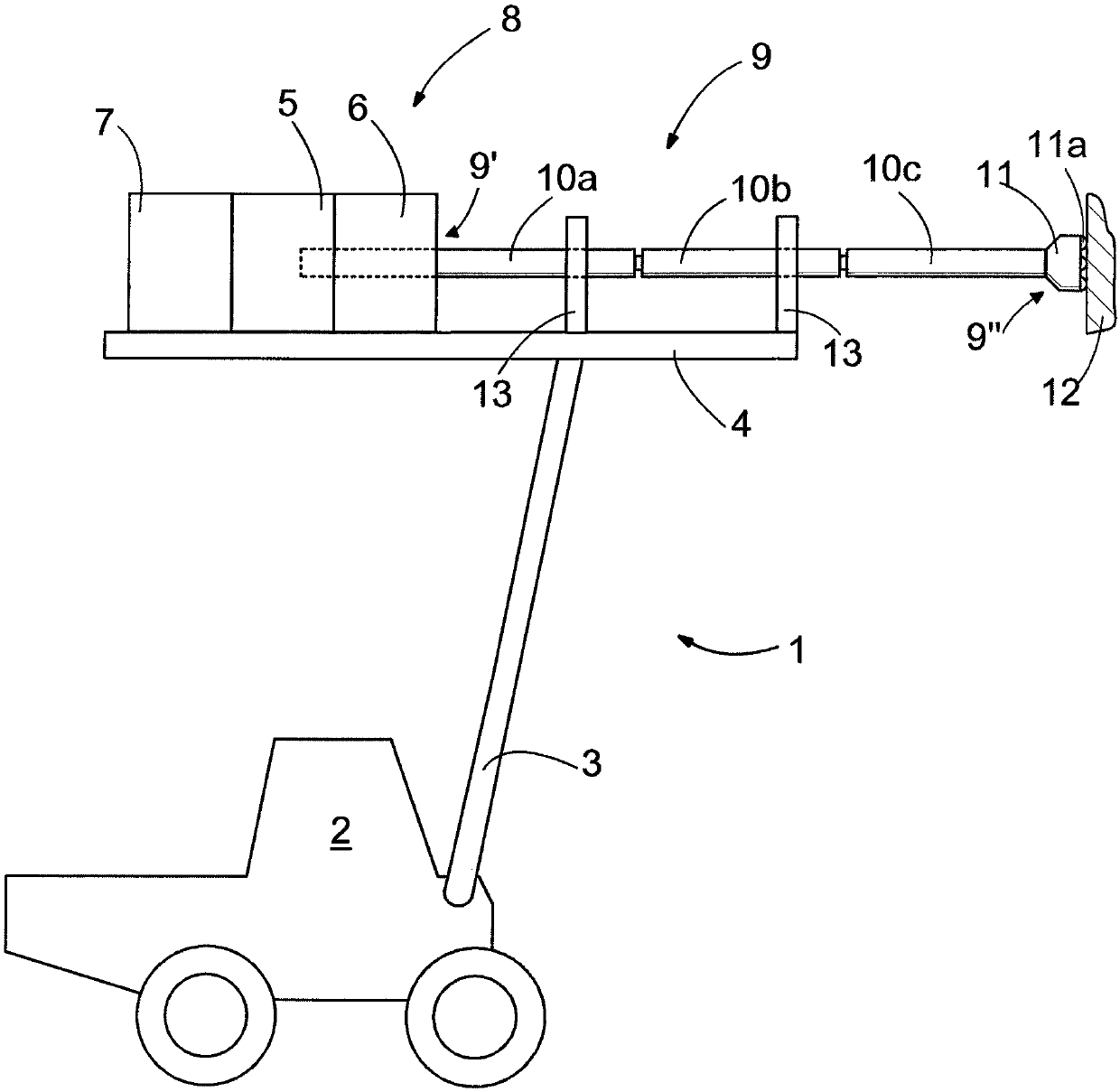

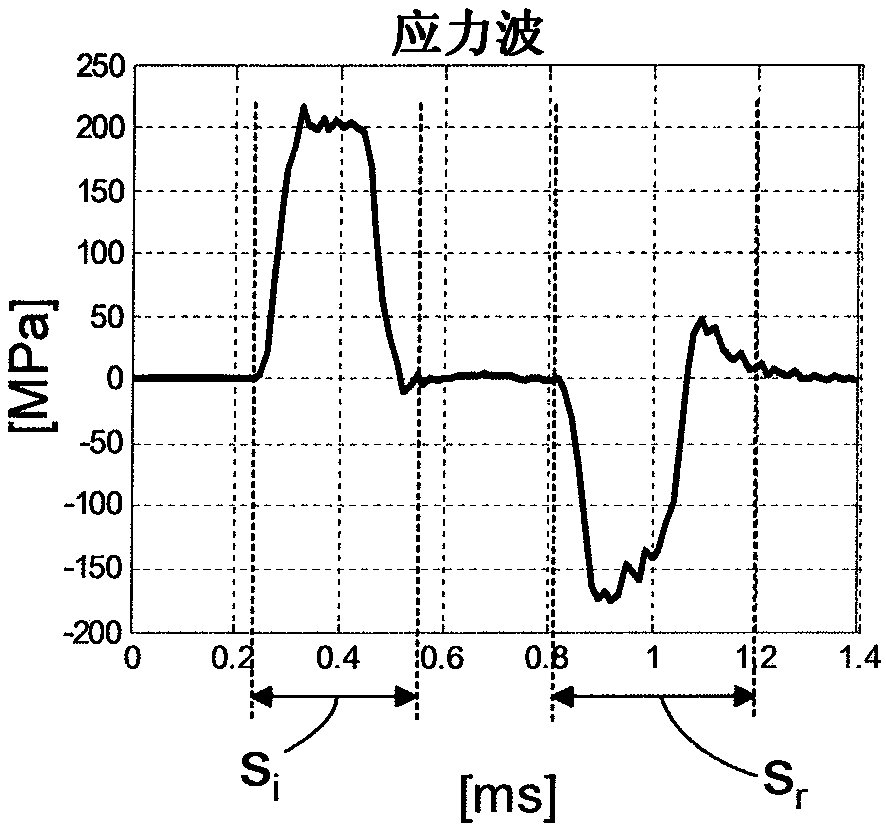

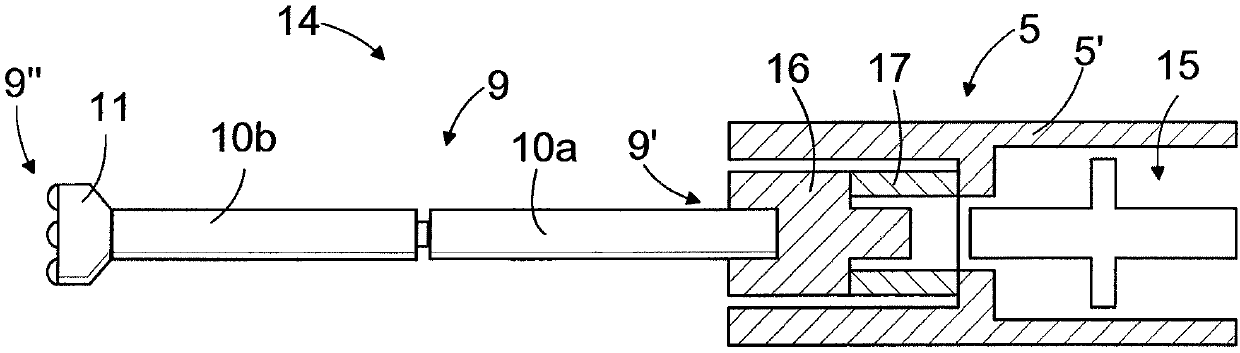

[0020] Rock breaking may be performed by drilling a hole in the rock by a rock drilling machine. Alternatively, the rock can be broken by a breaking hammer. In this context, the term "rock" should be interpreted broadly to also cover pebbles, rocky material, encrustations and other relatively hard materials. Rock drills and breakers include impact mechanisms that provide impact pulses to the tool directly or through an adapter. The shock pulse generates a stress wave that propagates in the tool. When the stress wave reaches the end of the tool facing the rock to be drilled, the tool penetrates the rock due to the influence of the stress wave. Some of the energy of the stress wave may be reflected back as a reflected wave that propagates in the tool in the opposite direction (ie, towards the impact mechanism). Depending on the situation, the reflected waves may contain only compressive stress waves or tensile stress waves. However, reflected waves generally include a tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com