A precise and fast calibration device for stylus and its working method

A stylus and calibration technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that no good solution has been found, no calibration, etc., and achieve the effects of easy automation, avoiding uncertain errors, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

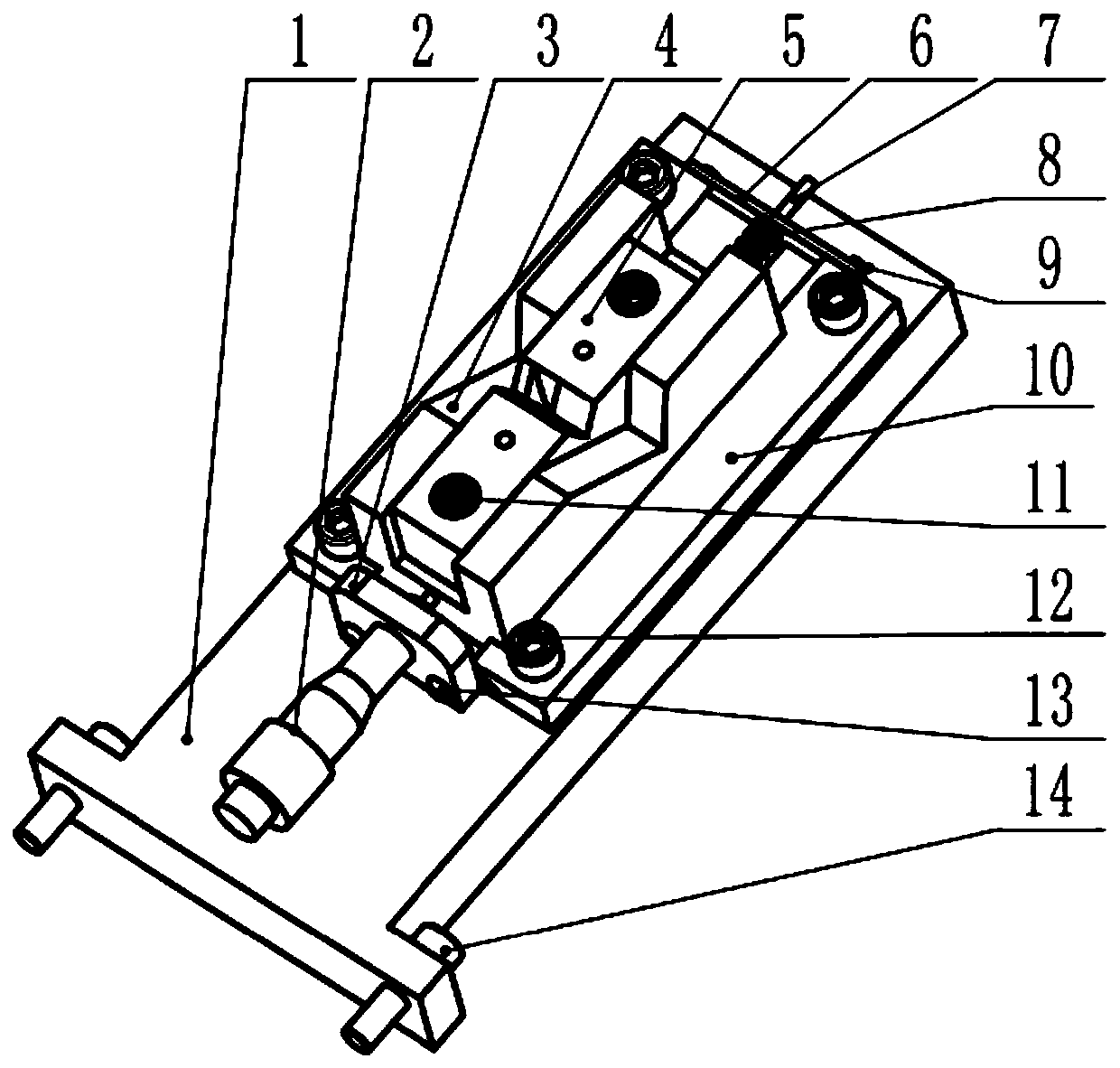

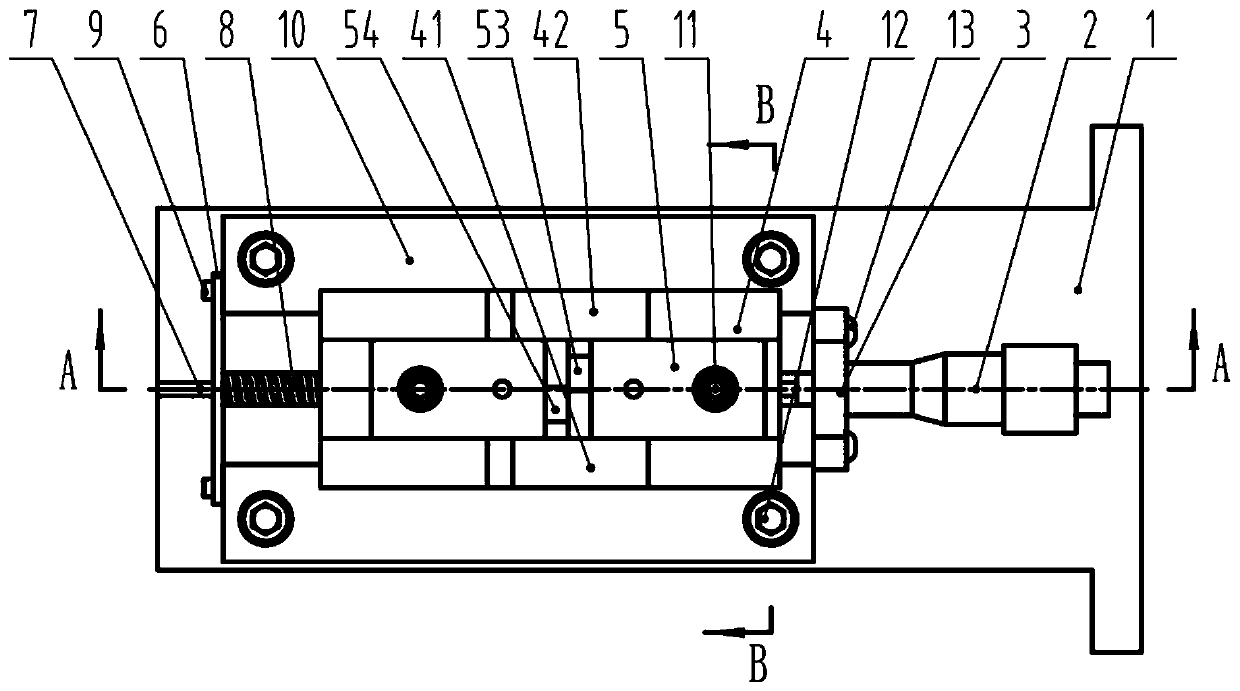

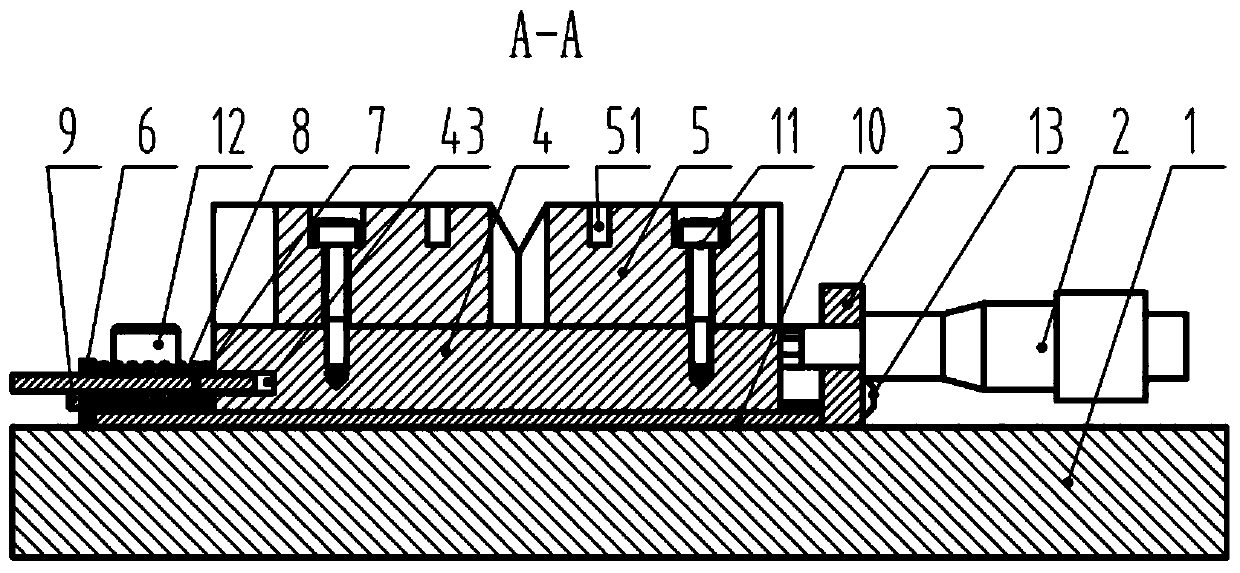

[0047] Such as Figure 1-13 As shown, a stylus precision rapid calibration device includes a support 1, a base 10, a high-level calibration module 5, a stylus levelness calibration and length self-inspection module 4, and a fine-tuning assembly;

[0048] The support 1 has a "T"-shaped structure. According to installation requirements, the support 1 is provided with corresponding through holes 51 and threaded holes 52, and the support 1 is connected and fixed on the mobile workbench of the machine tool through screws E14;

[0049] The base 10 is provided with a dovetail groove structure, and the base 10 is fixed on the support 1 by four screws C12.

[0050] The stylus levelness check and length self-inspection module 4 is provided with a chute A41 and a chute B42, the slope and height of the chute A41 and the chute B42 are consistent, and the stylus levelness check a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com