Fuel cell humidifier test platform

A test platform, fuel cell technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve problems such as battery scrapping, and achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

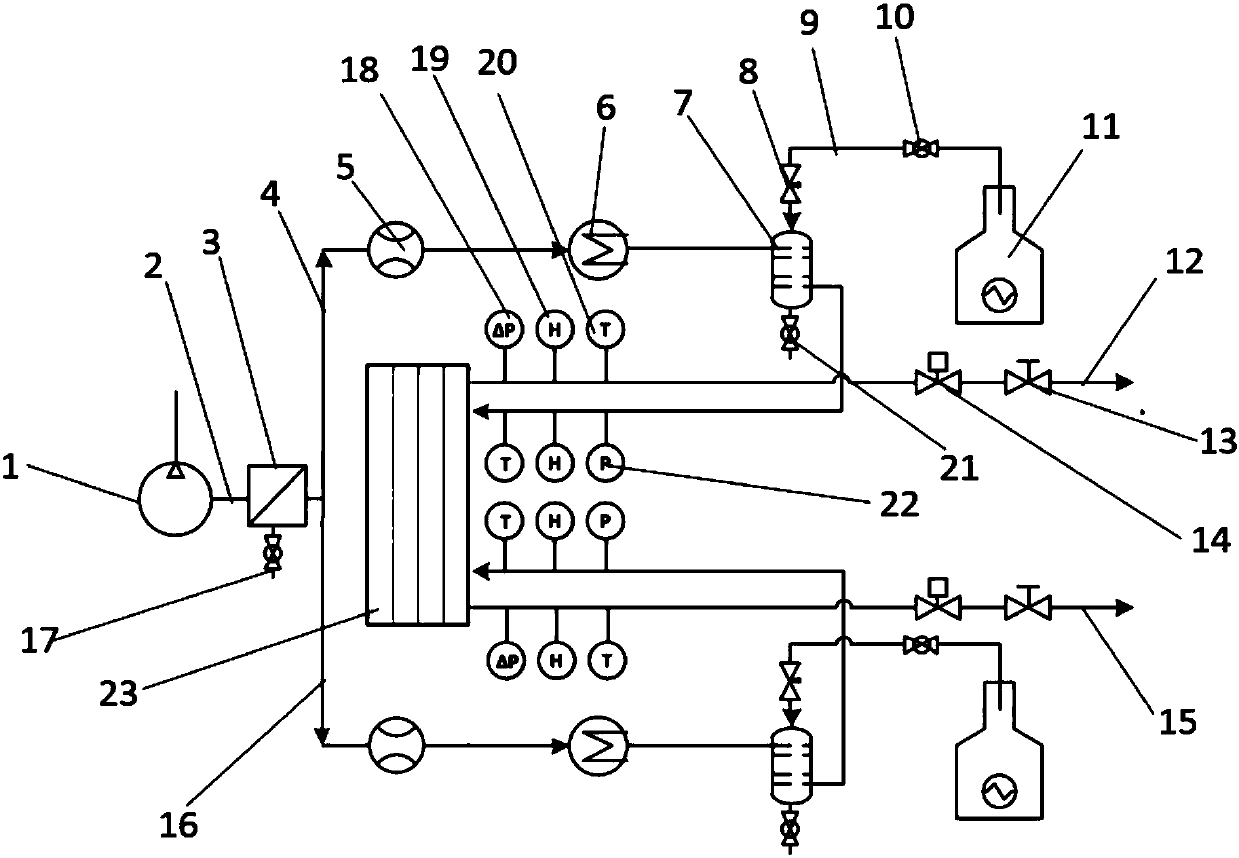

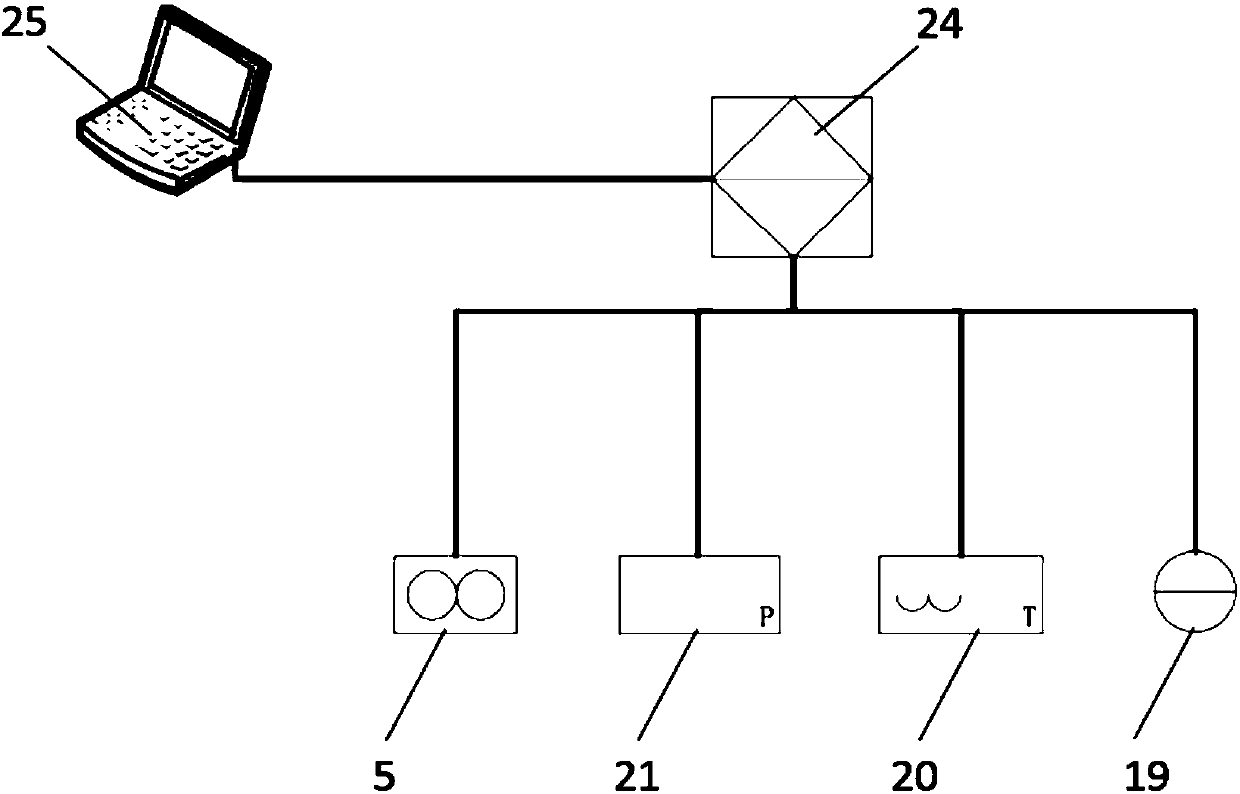

[0026] A fuel cell humidifier test platform includes a dry air generating unit, an air heating unit, an air humidifying unit, a data acquisition system and an automatic control system. among them,

[0027] Dry air generating unit: including air compressor 1, air filter 3. Among them, the air compressor 1 can compress air to above 0.6 MPa; the air filter 3 can filter out moisture, impurities, and oil in the compressed air. The drain valve 17 provided under the air filter 3 can be manually opened to discharge moisture, dust, oil, etc. in the air filter.

[0028] The air heating unit uses finned heaters 6 with two or more. Different numbers of heaters are turned on at different flow rates to meet the requirement that the temperature can reach the corresponding set value at each flow rate. The fin heater 6 is wrapped with a heat insulating material to isolate the influence of the external environment temperature on the performance of the heater and improve the heating effect.

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com