Full-automatic ice powder processing equipment

A cooking equipment, fully automatic technology, applied in lighting and heating equipment, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the problem of small application range, high labor intensity, and equipment Complexity and other issues, to achieve the design and installation flexibility, reduce labor intensity, and ensure the effect of hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

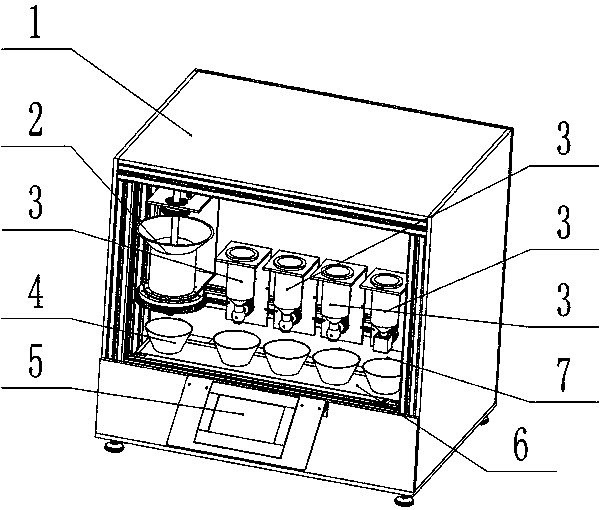

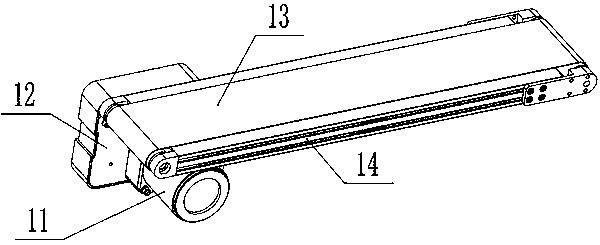

[0036]A fully automatic ice powder cooking equipment includes a cabinet 1, in which a crushed ice module 2 and a feeding module 3 are sequentially arranged, and a container 4 is arranged under the crushed ice module 2 and the feeding module 3, and the container 4 is placed on the conveying module 6, sensors 7 are provided at the outlets of the crushed ice module 2 and the feeding module 3, and an operation panel 5 is provided on the surface of the cabinet 1. The cabinet body 1 is used to integrate the conveying module 6, the crushed ice module 2, multiple feeding modules 3, the container 4, the operation panel 5 and the sensor 7 together. The ice crushing equipment and multiple feeding equipment are arranged along the conveying direction of the conveying equipment. The outlets of the ice crushing equipment and multiple feeding equipment are above the conveying equipment, facing the center of the conveying equipment, and the distance between the crushing ice equipment and the co...

Embodiment 2

[0038] A fully automatic ice powder cooking equipment includes a cabinet 1, in which a crushed ice module 2 and a feeding module 3 are sequentially arranged, and a container 4 is arranged under the crushed ice module 2 and the feeding module 3, and the container 4 is placed on the conveying module 6, sensors 7 are provided at the outlets of the crushed ice module 2 and the feeding module 3, and an operation panel 5 is provided on the surface of the cabinet 1. The cabinet body 1 is used to integrate the conveying module 6, the crushed ice module 2, multiple feeding modules 3, the container 4, the operation panel 5 and the sensor 7 together. The ice crushing equipment and multiple feeding equipment are arranged along the conveying direction of the conveying equipment. The outlets of the ice crushing equipment and multiple feeding equipment are above the conveying equipment, facing the center of the conveying equipment, and the distance between the crushing ice equipment and the c...

Embodiment 3

[0051] On the basis of Embodiments 1 and 2, the present invention will be further described below in conjunction with the accompanying drawings.

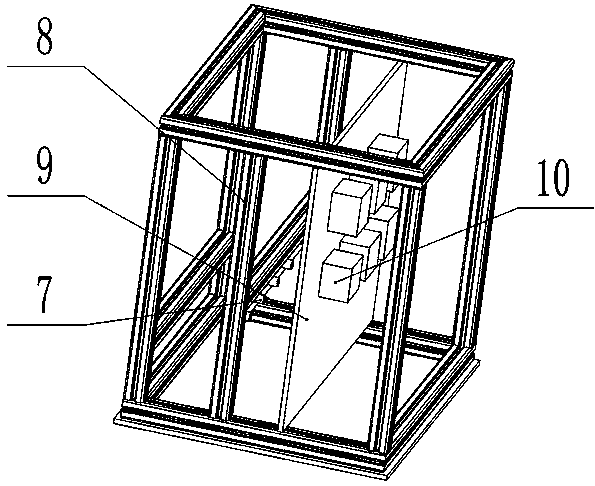

[0052] Such as figure 1 As shown, a fully automatic ice powder cooking equipment includes a cabinet body 1, a crushed ice module 2, multiple feeding modules 3, multiple containers 4, an operation panel 5, a conveying module 6, and multiple sensors 7. The crushed ice module 2 and a plurality of feeding modules 3 are arranged side by side inside the cabinet body 1 along the conveying direction of the conveying module 6, and its discharge port is above the conveying module 6, facing the center of the conveying module 6, and between the conveying module 6 The distance should be greater than the height of the container 4, and multiple containers 4 are placed on the conveyor belt of the conveying module 6, move along the conveyor belt of the conveying module 6, and pass directly below the outlets of the crushed ice module 2 and multiple f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com