Horizontal multi-shaft bearing type solid-phase reaction kettle

A technology of solid-phase reaction and reactor, which is applied in the field of horizontal multi-bearing pressure solid-phase reactor, can solve the problems of low production efficiency and heating efficiency, increase production, reduce labor cost and time cost, and completely discharge materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

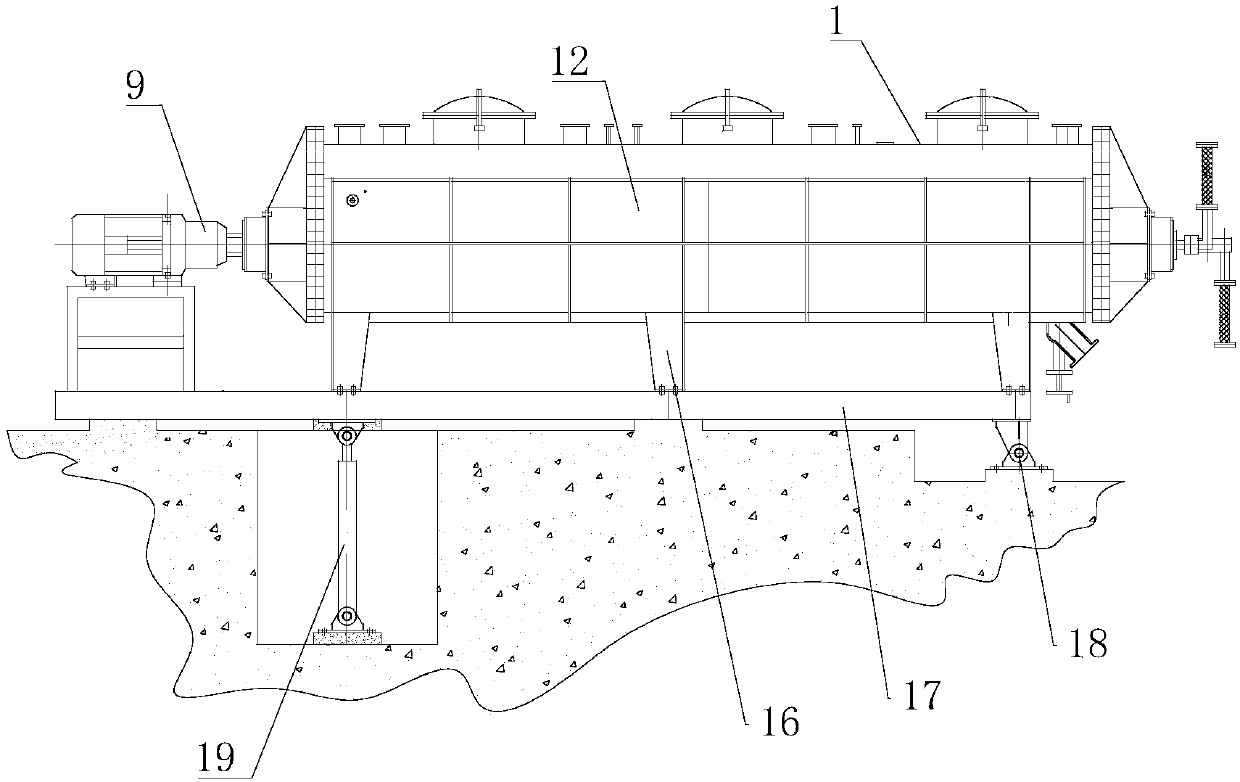

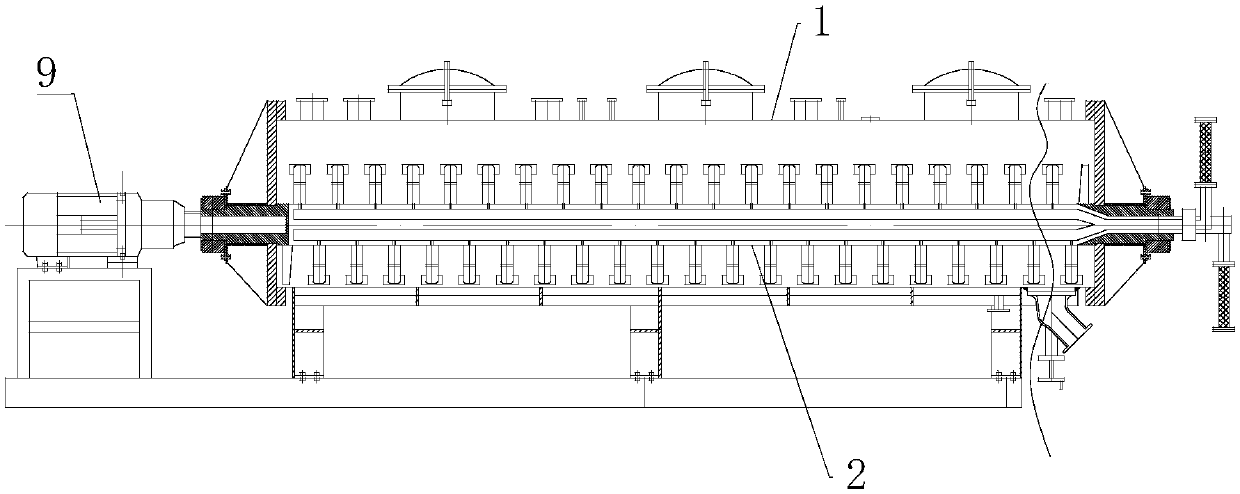

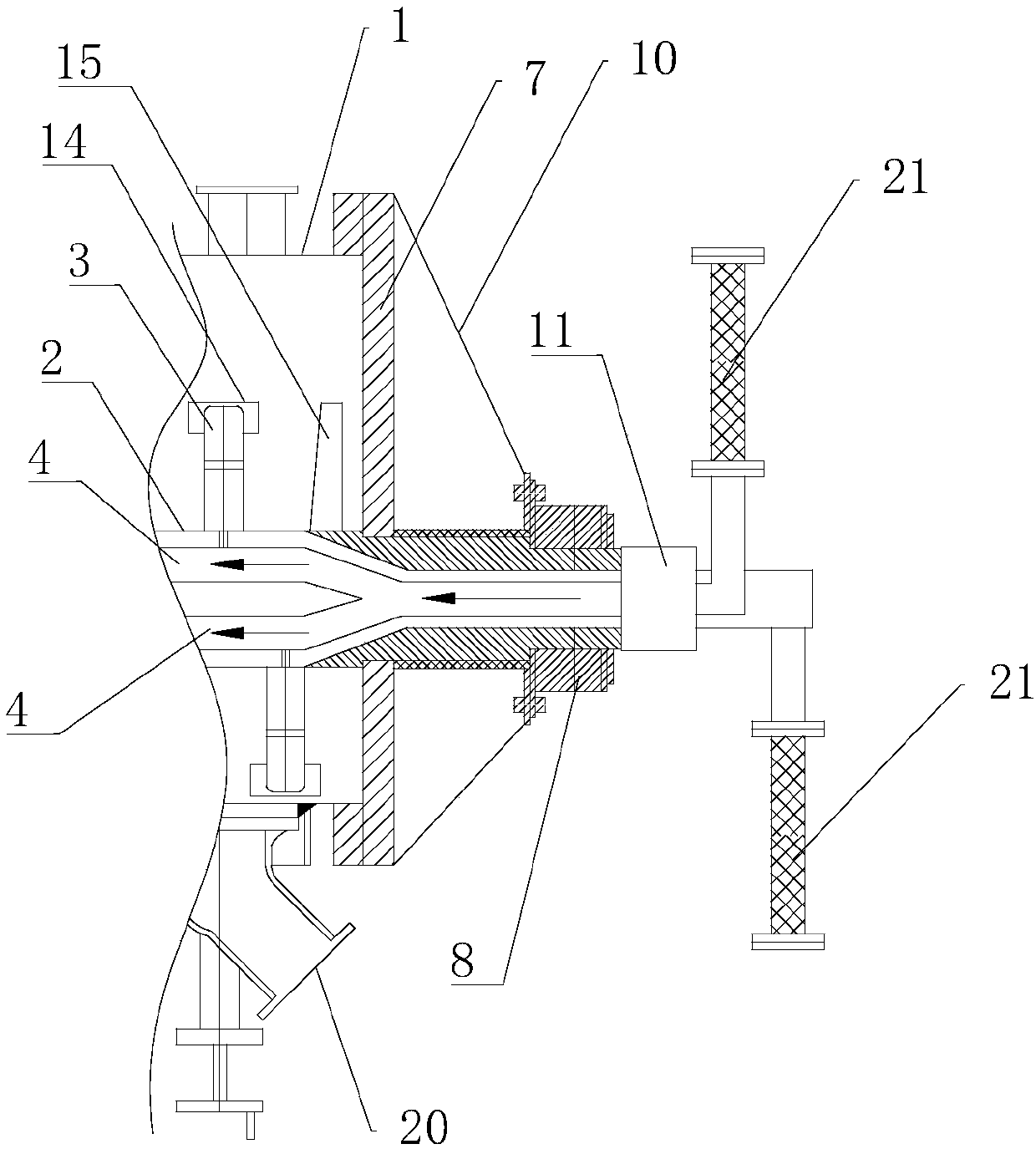

[0043] Such as figure 1 , figure 2 , image 3 and Figure 4 Commonly shown, it is an embodiment of the horizontal multi-bearing pressure solid-phase reactor of the present invention. This embodiment firstly includes a horizontally placed reactor cylinder 1, and at least two reactor cylinders are arranged side by side in the reactor cylinder 1. (Three in this embodiment) agitating shaft 2 of hollow structure, the two ends of described agitating shaft 2 all protrude from the two ends of reactor shell 1 and support on the bearing block 8, wherein, the left end of agitating shaft 2 Closed and connected with a motor 9 that drives its rotation. Two rows of circumferentially symmetrical stirring paddles 3 are fixed on each of the stirring shafts 2, and the stirring paddles 3 have a hollow fan-shaped structure.

[0044] The right end of the stirring shaft 2 is provided with a dual-path rotary joint 11 communicating with its inner cavity. At the same time, the inner cavity of the ...

Embodiment 2

[0057] Such as Figure 5 As shown, it is a schematic cross-sectional view of another structure of the reactor cylinder. The difference between it and Embodiment 1 is that the number of stirring shafts 2 in this embodiment is two, and the cross-section of the reactor cylinder is a rectangular structure. Moreover, the gap between the upper edge of the stirring paddle and the top surface of the reactor cylinder is less than 5cm. The rest of the structure in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

Embodiment 3

[0059] Such as Figure 6 As shown, it is a cross-sectional schematic diagram of another structure of the reactor cylinder, and its difference from Example 1 is that the cross-section of the reactor cylinder in this embodiment is oblong, and the upper edge of the stirring blade is in line with the The gap between the top surfaces of the reactor cylinders is less than 5cm. The rest of the structure in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

[0060] The horizontal multi-bearing pressure solid-phase reactor of the invention has simple structure, convenient use, higher production efficiency and heat transfer efficiency than traditional reactors, and good practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com