Vibration screening device for prefabricated slab concrete in building construction

A vibrating screening and building construction technology, which is applied in the fields of filtering, solid separation, chemical instruments and methods, etc., can solve the problems of large vibrating machine, unable to replace the mesh, and reduced vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

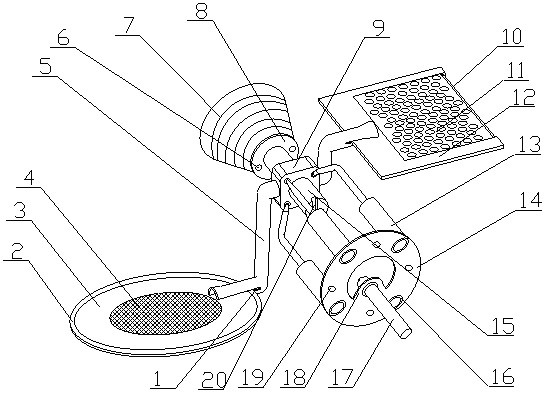

[0022] A kind of prefabricated slab concrete vibration screening device for building construction of the present invention is realized in this way, when in use, when material is screened, at first install and fix the mounting plate 14 in an appropriate position through a plurality of mounting holes 19 on the mounting plate 14, and The annular supporting plate 3 and the fixed frame 12 are correspondingly suspended above the agitator, and then the other end of the drive shaft 17 is connected to the external motor, and the other end is connected to the transmission shaft 15 through a bar-shaped protrusion, because the drive shaft 17 and the transmission shaft 15 Eccentric, so the bar-shaped groove on the drive shaft 15 and the bar-shaped protrusion on the drive shaft 17 partially cooperate, and the drive shaft 17 drives the drive shaft 15 to rotate. Due to the force on one side of the drive shaft 17, it will swing during the rotation. The motion track of the driving shaft 17 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com