Processing technology of ETPU damping midsole with compact outer surface

A kind of processing technology and dense technology, which is applied in the processing technology field of ETPU shock absorption midsole with dense appearance, which can solve the problems of affecting the appearance of shoes, easy accumulation of stolen goods, and difficulty in cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0025] The present invention relates to a kind of processing technology of dense ETPU shock-absorbing midsole, comprising the following steps:

[0026] ①Inject the TPU expanded particles into the mold of the expanded particle molding machine, heat treatment with steam, and obtain the conventional TPU expanded particle molded body after cooling with cooling water, draining, air cooling and demoulding;

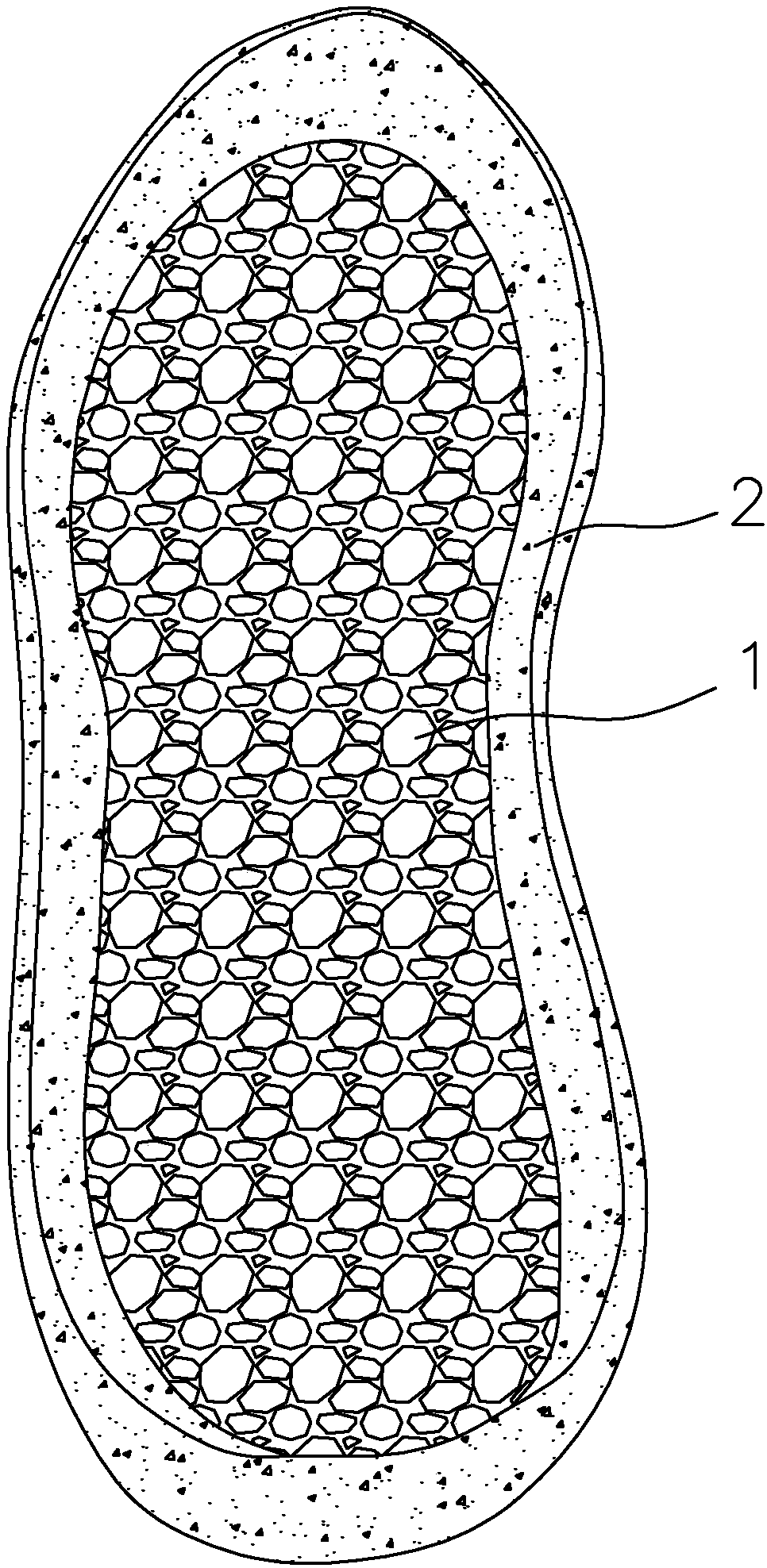

[0027] ②Put the TPU expanded particle molded body obtained in step ① into the secondary molding mold, and perform rapid heating and rapid cooling on the annular side edge to melt the surface and interface of the formed TPU expanded particle to form a dense layer , to get a compact ETPU shock-absorbing midsole. Such as figure 1 As shown, the dense layer corresponds to the annular side edge 2, and the shock-absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com