Ethene compressor cleaning media

A compressor, ethylene technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of poor adaptability of cracking raw materials, side effects of subsequent devices, and insignificant anti-scaling effect, and achieves low cost, strong adaptability, Good anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

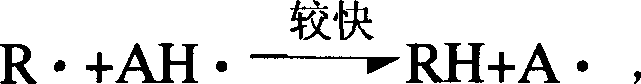

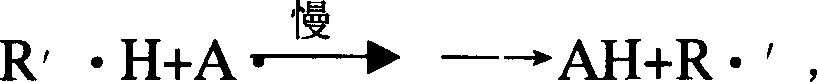

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 120g of 2,6-di-tert-butyl-p-cresol and 410g of kerosene into a container respectively, raise the temperature to 80°C, stir at a constant temperature to completely dissolve the p-cresol, then cool to room temperature, and while stirring, Add 350g of dibutyl phosphite and 120g of tetradecyl dimethyl tertiary amine respectively, and after they are fully mixed, filter to obtain the antiscalant agent code HK-1.

[0042] The anti-scaling agent code-named HK-1 is evaluated in the laboratory for its anti-scaling effect. The method is as follows:

[0043] (1) Evaluation method

[0044] The evaluation device for anti-scaling effect of anti-scaling agent is designed according to the principle of heat transfer. It uses a heat pipe to allow the medium to flow continuously in the heat pipe. At the beginning, because the medium has not scaled on the heat pipe, the total heat transfer resistance is only the heat transfer resistance of the heat pipe wall; as the running time increa...

Embodiment 2

[0055] Components are 50g 2,6-di-tert-butylphenol, 400g triphenyl phosphate, 60g dodecyl dimethyl tertiary amine, 490g toluene, and others are the same as in Example 1.

Embodiment 3

[0057] Components are 20g 2-tert-butyl-4,6-dimethylphenol, 200g triethyl phosphate, 300g trioctyl tertiary amine, 460g toluene, and others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com