Cloth dyeing technology

A fabric and process technology, applied in the field of fabric dyeing technology, can solve the problems of aggravating the wrinkle degree of the fabric, increasing the milling time and difficulty of milling, and complicated procedures, so as to promote the dyeing speed, reduce the milling process, and prevent the dye from precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed explanation through specific implementation mode below:

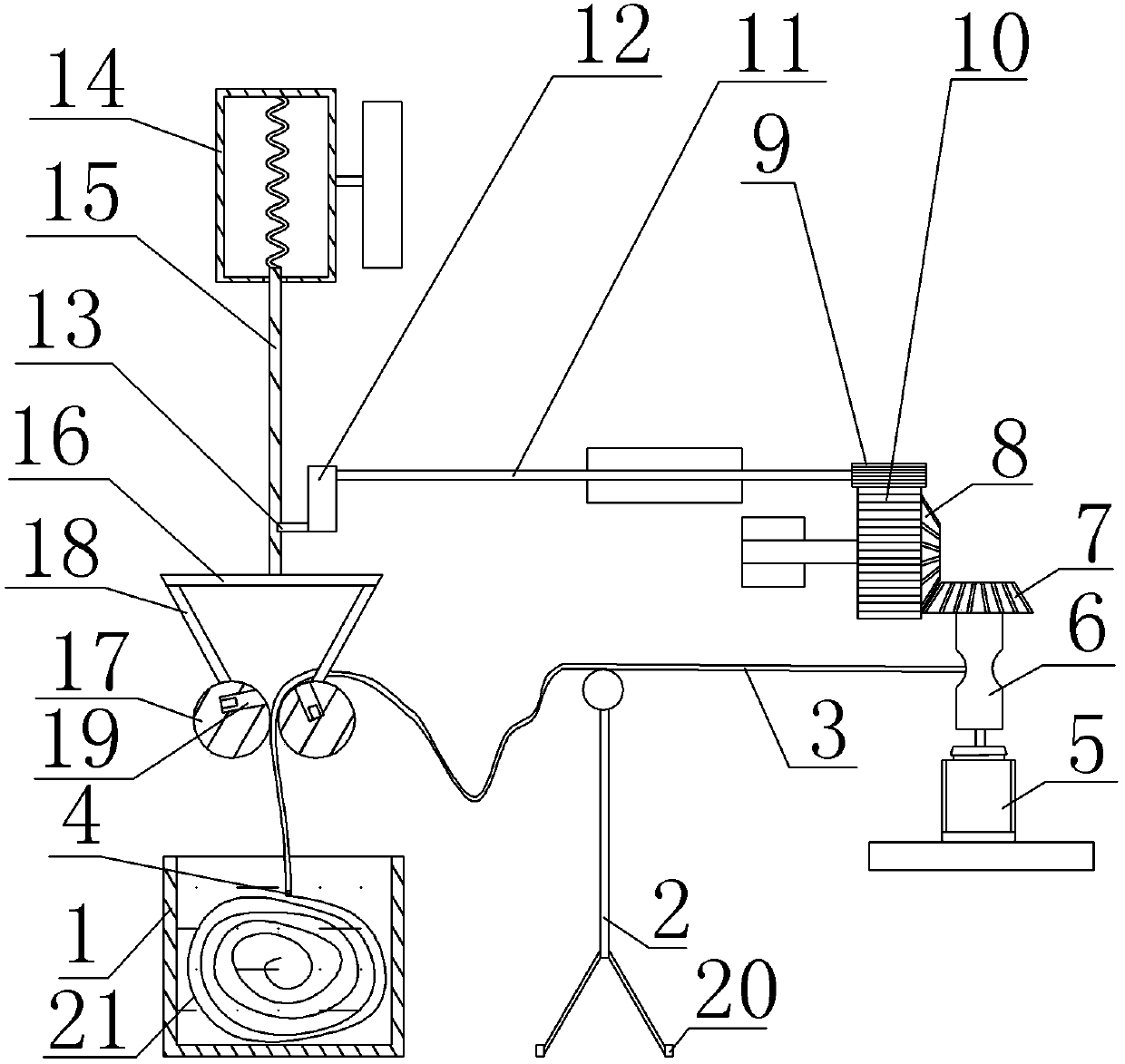

[0017] The reference signs in the drawings of the description include: dye vat 1, drying rack 2, lifting rope 3, lifting rod 4, motor 5, winding roller 6, No. 1 bevel gear 7, No. 2 bevel gear 8, and No. 1 gear 9, No. 2 gear 10, turning bar 11, turning block 12, connecting rod 13, swing box 14, swing bar 15, support plate 16, clamping roller 17, support bar 18, groove 19, roller 20, cloth 21.

[0018] The fabric dyeing process specifically includes the following steps:

[0019] Step 1: Prepare a dye, including 12 parts of mica powder, 24 parts of butyl methacrylate, 28 parts of calcium trichloride, 25 parts of acetone, 24 parts of potassium hydroxide, polyoxalic acid fatty acid 25 parts of ester, 15 parts of azodicarbonamide, 15 parts of polyacrylamide, 45 parts of sodium dodecylbenzenesulfonate, and the balance is water, mix well and set aside;

[0020] Step 2: Prepare as figure 1 The cloth dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com