Cooling circulation system for locomotive

A circulation system and locomotive technology, applied in the direction of cooling/ventilation of locomotives, substations/switchgear, etc., can solve the problems of inconvenient equipment layout in the machine room, increase the heat dissipation load of the machine room, and low cooling efficiency, so as to achieve the convenience of the machine room Equipment layout, cabinet size reduction, and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

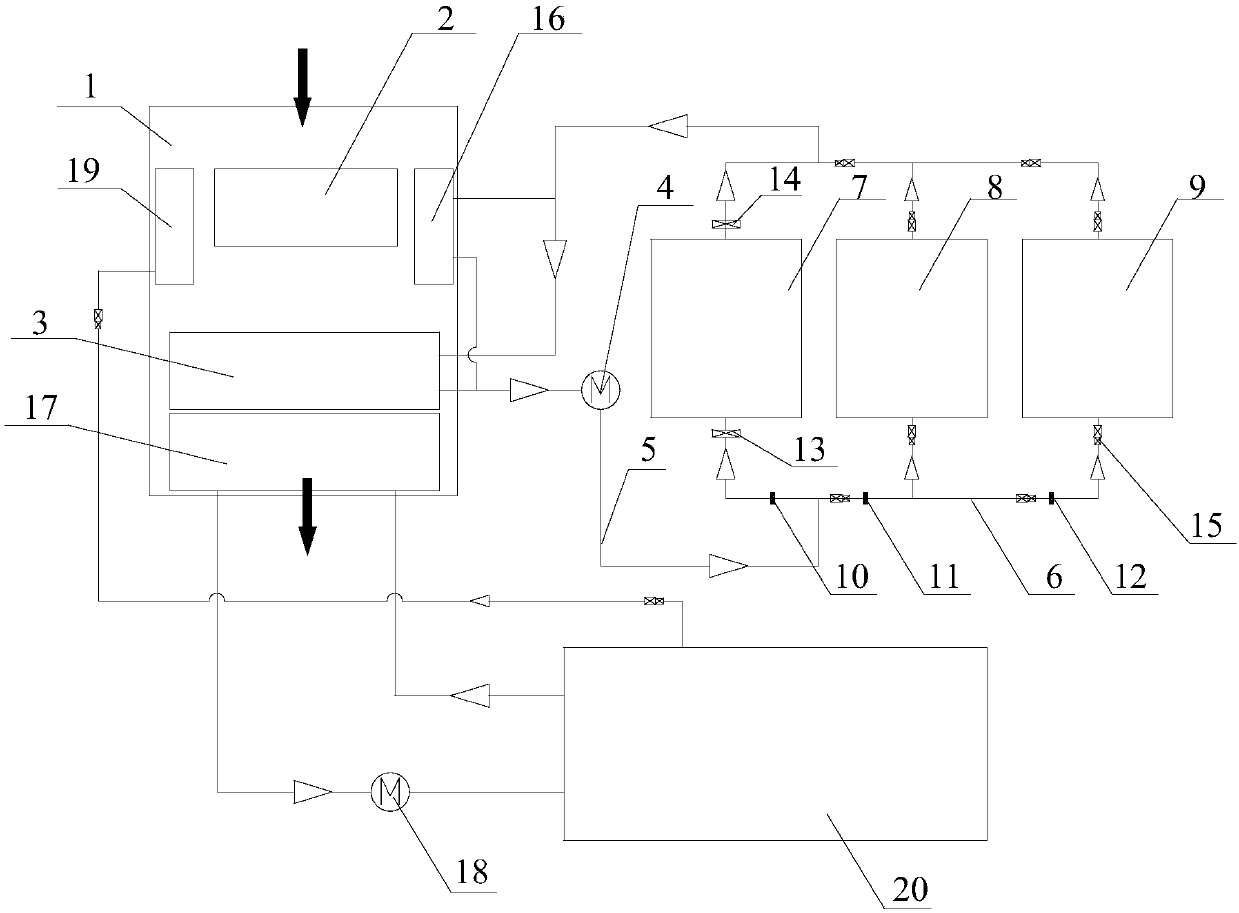

[0050] Such as figure 1 As shown, the present invention discloses a cooling cycle system for a locomotive. The cooling cycle system for a locomotive includes a cooling tower 1 , a main cooling fan 2 , a water radiator 3 , a water pump 4 , an output water pipe 5 and a first pipe 6 .

[0051] Wherein, the main cooling fan 2 and the water radiator 3 are all arranged in the cooling tower 1 outside the car body, the main cooling fan 2 can blow the cold wind at the inlet of the cooling tower 1 to the water radiator 3, and the inlet of the water pump 4 and the water radiator The outlet of the device 3 is connected, and the cooling liquid can be pumped out from the water radiator 3.

[0052] The inlet of the output water pipe 5 is connected with the outlet of the water pump 4 , and the outlet of the output pipe is connected with the inlet of the first pipeline 6 . The first pipeline 6 connects the main converter cabinet 7 , the train power supply cabinet 8 and the cooling equipment 9...

Embodiment 2

[0055] In the second embodiment provided by the present invention, the locomotive cooling circulation system in this embodiment is similar in structure to the locomotive cooling circulation system in Embodiment 1, and the similarities will not be repeated, and only the differences will be introduced. place.

[0056] In this embodiment, it is specifically disclosed that the cooling circulation system for a locomotive further includes a first filter 10 , a second filter 11 and a third filter 12 . Wherein, the first filter 10, the second filter 11 and the third filter 12 are respectively arranged at the entrance of the main converter cabinet 7, the entrance of the train power supply cabinet 8 and the entrance of the cooling equipment 9, and are respectively used to filter the The inlet of the converter cabinet 7, the inlet of the train power supply cabinet 8 and the coolant of the cooling equipment 9. The purpose of setting the first filter 10, the second filter 11 and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com