Method for preparing tin niobate nanospheres by using alcohol solvent heat

A tin niobate and alcohol solvent technology, applied in chemical instruments and methods, niobium compounds, physical/chemical process catalysts, etc., to achieve good repeatability, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

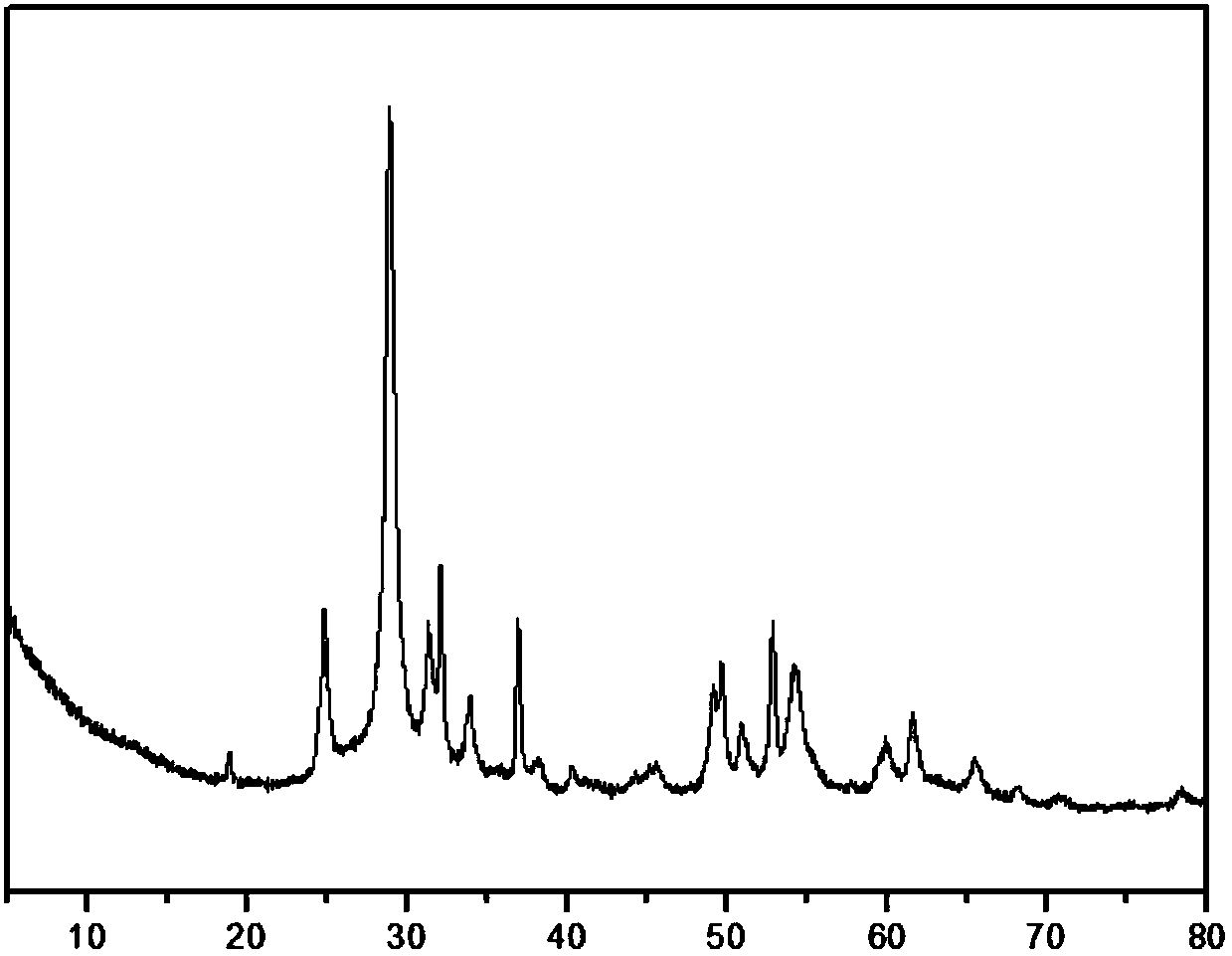

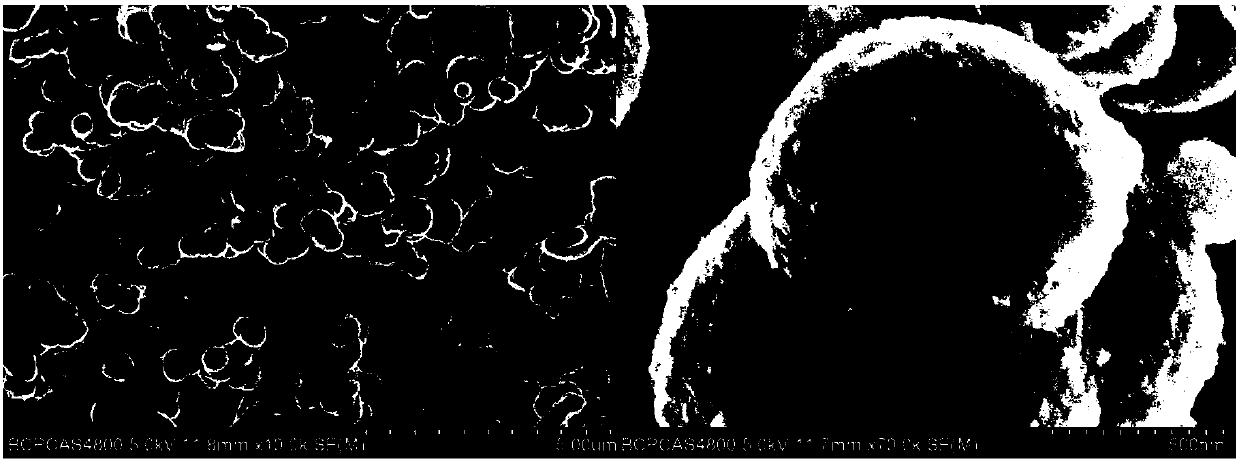

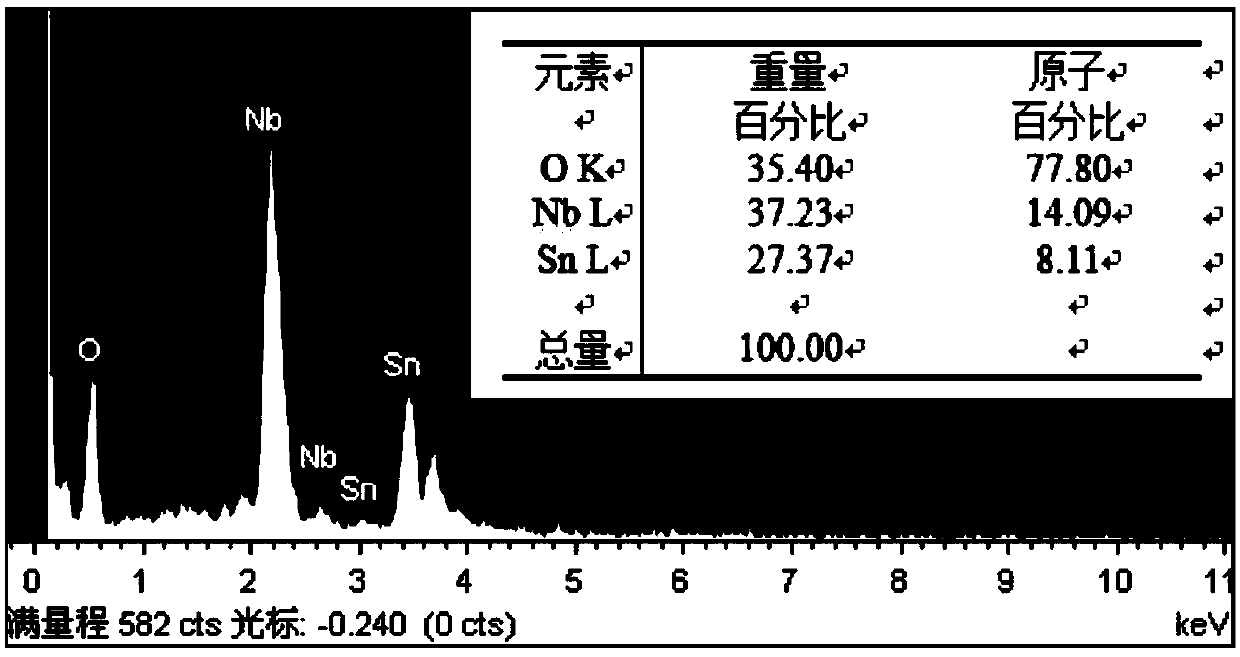

Embodiment 1

[0019] (1) First dissolve stannous chloride (SnCl) with deionized water 2 2H 2 O), and with niobium pentoxide (Nb 2 o 5 ) powders are mixed to form a paste, and then organic alcohols (ethanol) and surfactant polyvinylpyrrolidone (PVP) are added;

[0020] (2) Using the solution obtained in step (1) as the reaction precursor, it was heat-treated in a closed reactor with a volume of 20mL at a temperature of 160°C for 48 hours, and SnNb was successfully prepared. 2 o 6 nanospheres;

[0021] where SnCl 2 2H 2 O, Nb 2 o 5 , PVP were used in amounts of 0.4g, 0.4g, 0.1g; deionized water and alcohol were used in amounts of 2mL, 8mL.

Embodiment 2

[0023] (1) First dissolve stannous chloride (SnCl) with deionized water 2 2H 2 O), and with niobium pentoxide (Nb 2 o 5 ) powders are mixed to form a paste, and then organic alcohols (ethanol) and surfactant polyvinylpyrrolidone (PVP) are added;

[0024] (2) Using the solution obtained in step (1) as the reaction precursor, it was heat-treated in a closed reactor with a volume of 20mL at a temperature of 180°C for 48 hours, and SnNb was successfully prepared. 2 o 6 nanospheres;

[0025] where SnCl 2 2H 2 O, Nb 2 o 5 , PVP were used in amounts of 0.5g, 0.3g, 0.1g; deionized water and alcohol were used in amounts of 2mL, 8mL.

Embodiment 3

[0027] (1) First dissolve stannous chloride (SnCl) with deionized water 2 2H 2 O), and with niobium pentoxide (Nb 2 o 5 ) powders are mixed to form a paste, and then organic alcohols (ethanol) and surfactant polyvinylpyrrolidone (PVP) are added;

[0028] (2) Using the solution obtained in step (1) as the reaction precursor, it was heat-treated in a closed reactor with a volume of 20mL at a temperature of 180°C for 48 hours, and SnNb was successfully prepared. 2 o 6 nanospheres;

[0029] where SnCl 2 2H 2 O, Nb 2 o 5 , PVP were used in amounts of 0.4g, 0.2g, 0.08g; deionized water and alcohol were used in amounts of 2mL, 8mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com