White polyurethane paint capable of highly highlighting wood grains

A polyurethane, white technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of oil accumulation in the wood eye, no oil in the wood diameter, sagging, etc., and achieve the effect of smooth wood grain and smooth wood diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of polyurethane wood paint

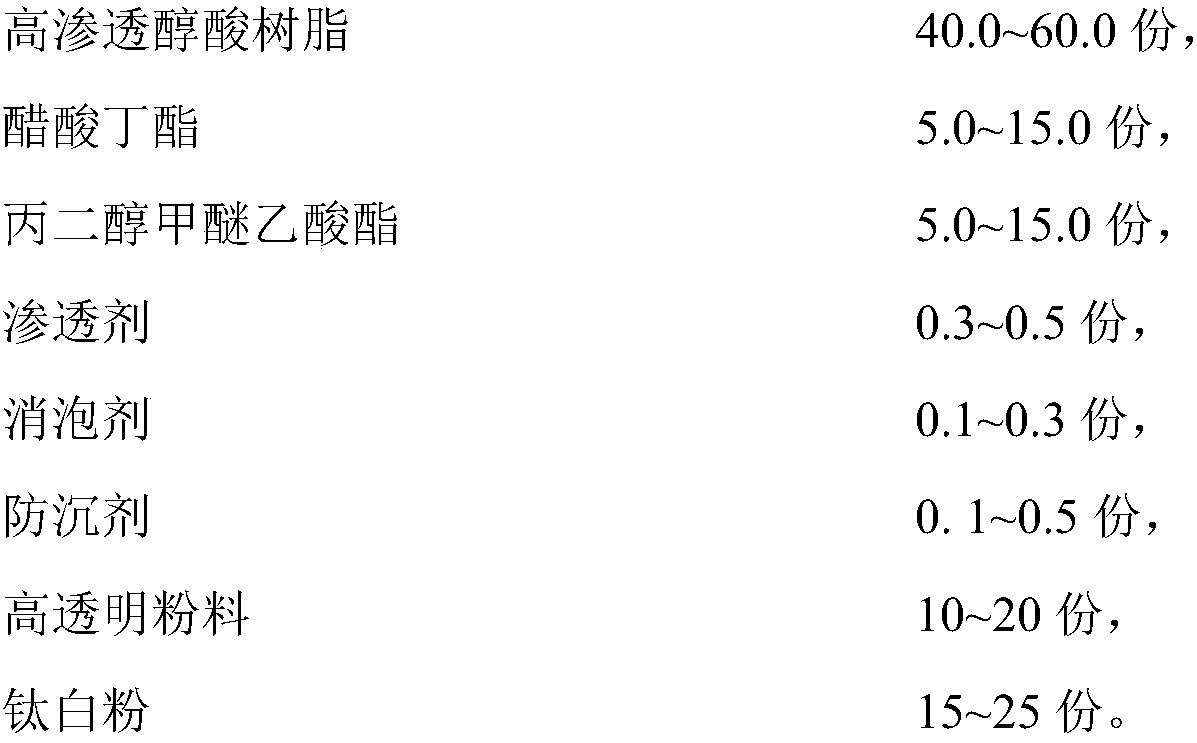

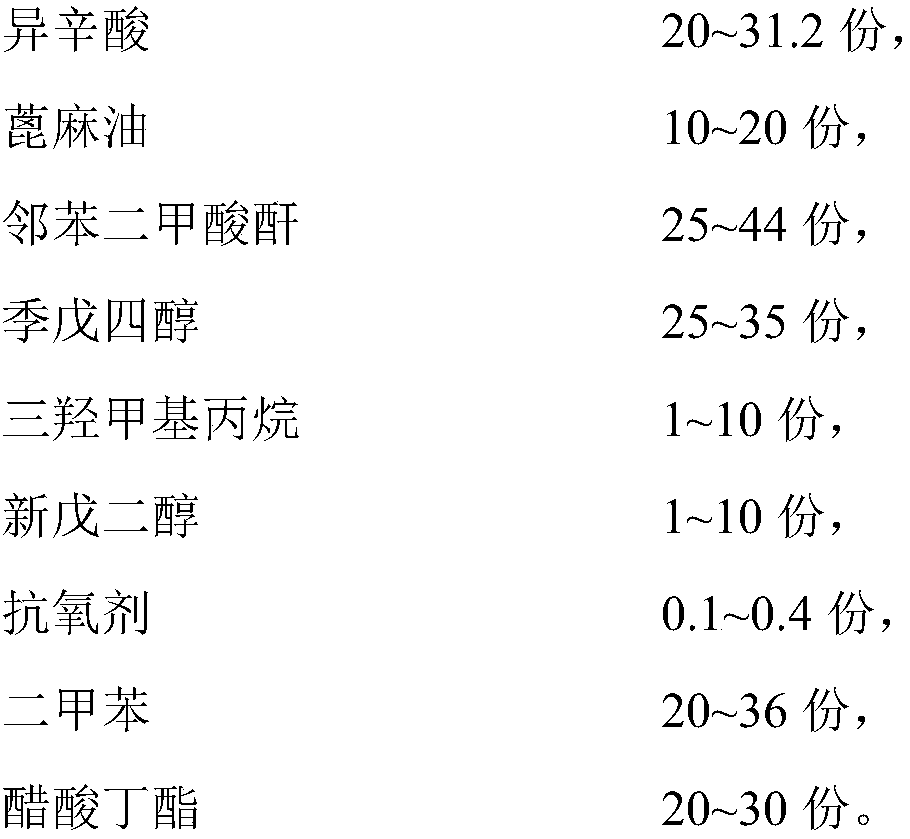

[0037] 1.1. Formula of high penetration alkyd resin

[0038] Each raw material component of described high penetration alkyd resin is as follows: 3120 kilograms of isooctanoic acid, 1440 kilograms of castor oil, 4400 kilograms of phthalic anhydride, 3150 kilograms of pentaerythritol, 525 kilograms of trimethylolpropane, 275 kilograms of neopentyl glycol , 40 kg of antioxidants, 3,600 kg of xylene, and 2,850 kg of butyl acetate. 1.2, the preparation method of high permeability alkyd resin

[0039] The preparation method of described high penetration alkyd resin comprises the steps:

[0040] 1), take each raw material component by formula quantity;

[0041] 2), isocaprylic acid, castor oil, phthalic anhydride, pentaerythritol, trimethylolpropane, neopentyl glycol, antioxidant, and the xylene that accounts for 5% of the total weight of xylene are dropped into the reactor successively, and the temperature rises Keep warm at 1...

Embodiment 2

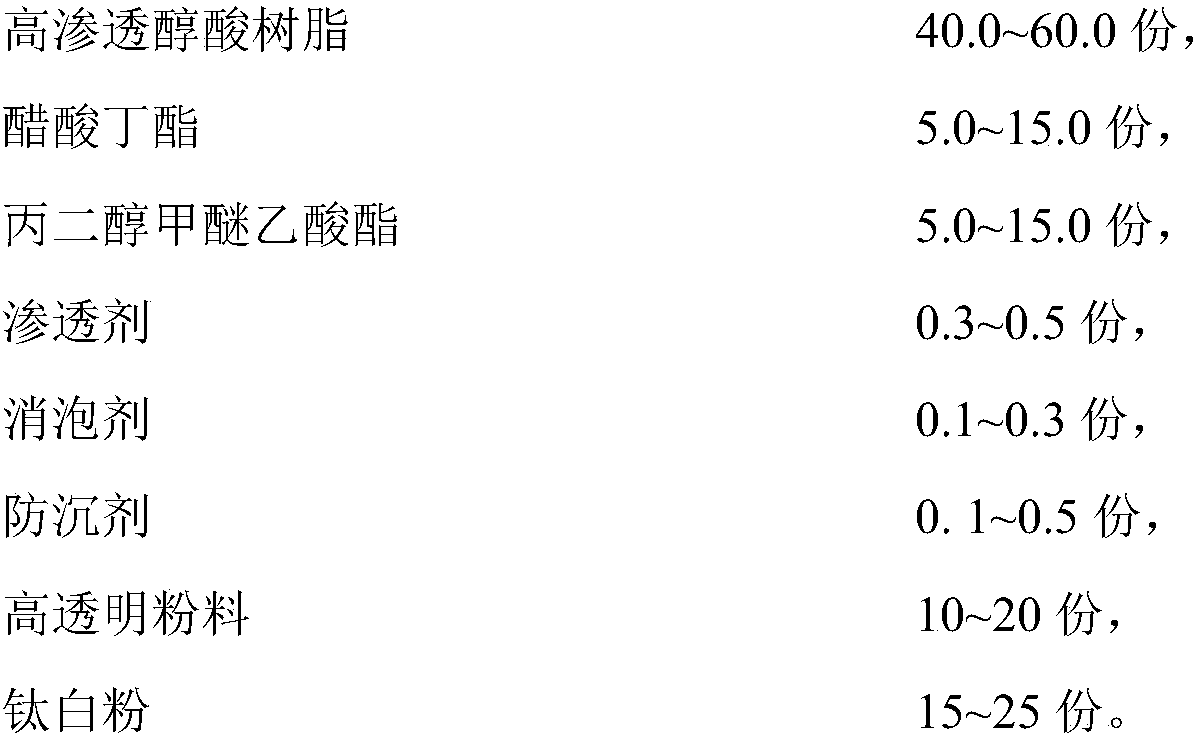

[0067] 1. Preparation of main agent of color paint

[0068] The main ingredient of the color paint is taken as follows: get 53.9 kilograms of the high-permeability alkyd resin obtained in Example 1, 5 kilograms of butyl acetate, 5 kilograms of propylene glycol methyl ether acetate, 0.3 kilograms of penetrant, and 0.3 kilograms of defoamer. kg, 0.5 kg of anti-settling agent, 10 kg of highly transparent powder, and 25 kg of titanium dioxide.

[0069] The penetrating agent is OMG (Ou Enji) Borchi gen 0451 non-ionic polyurethane dispersion penetrating agent, the defoamer is Huaxia HX2300 foam-breaking polymer and polysiloxane solution; the anti-settling agent is Disparon's 6900 -X-20 polyamide wax slurry; the highly transparent powder is 706 anti-sinking powder of Sibick; the titanium dioxide is DuPont R-900 rutile titanium dioxide.

[0070] The preparation method of the paint main agent adopts the preparation method of Example 1.

[0071] 2. Preparation of curing agent

[0072...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com