A kind of solid wood multi-layer board bending back manufacturing method

A production method and multi-layer board technology, which are applied in the direction of wood bending, wood veneer bonding, and manufacturing tools, etc., can solve the problems of unclear background, affect the appearance, and increase the number of processes, so as to facilitate production and modification, and save money. Production process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

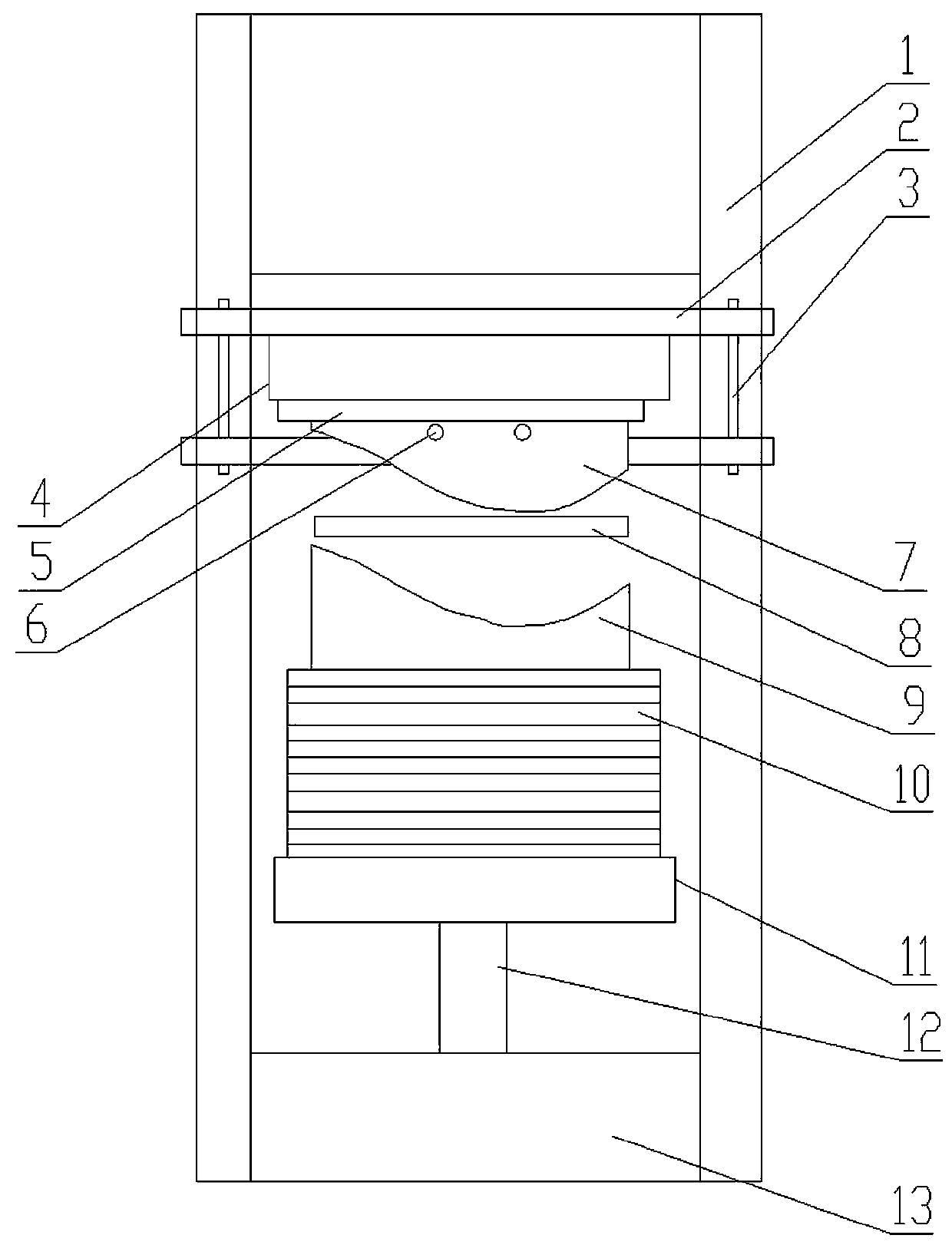

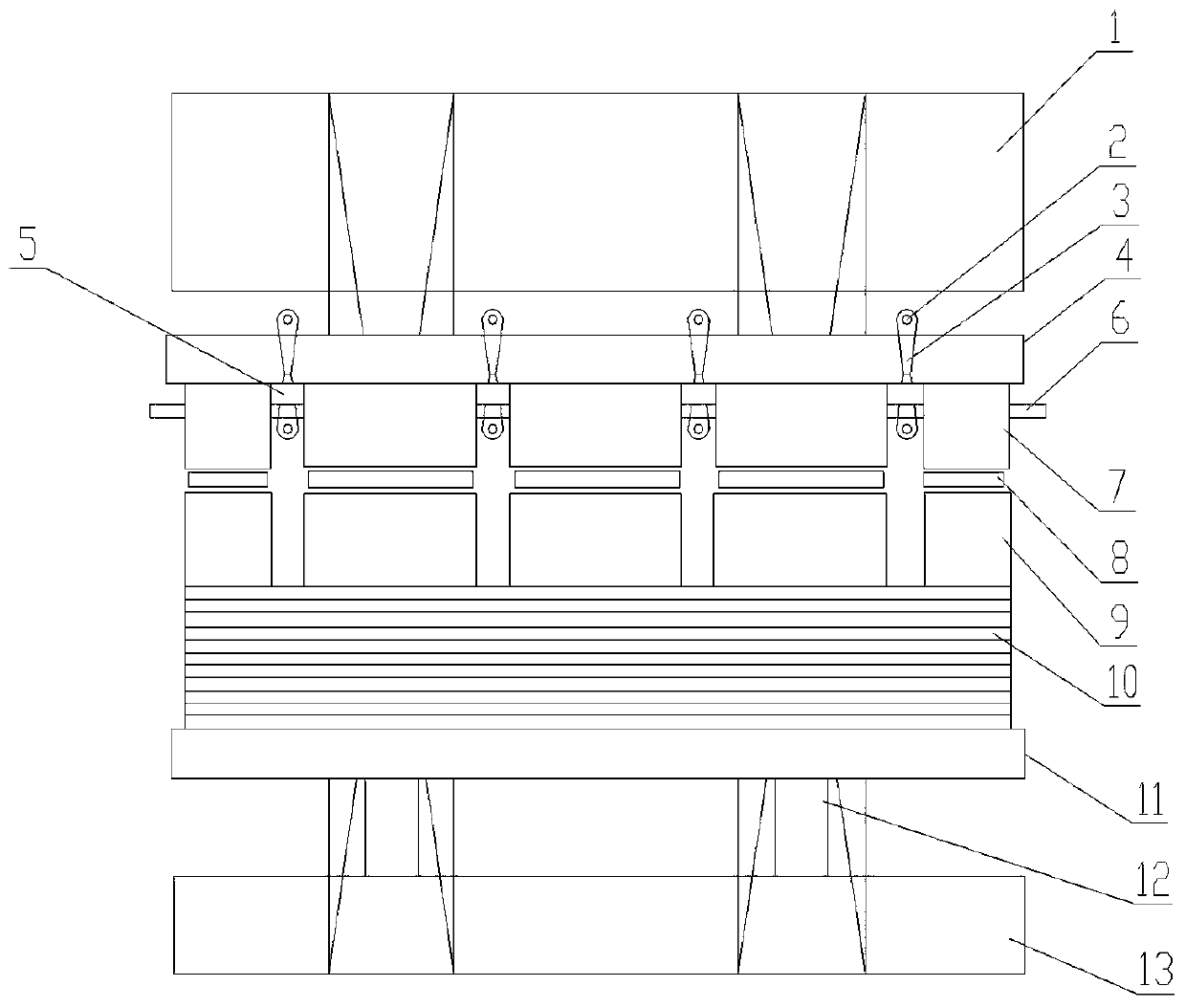

[0029] Embodiment: make the multilayer board S curved back on the solid wood curved back bed with a specification of 500*180*25mm, make the upper part 7 of the bending mold and the lower part 9 of the bending mold according to the pairing of the multilayer board S curved back, and the long side is larger than the multilayer board S The long side of the curved back is 100mm, that is, 600mm; the short side is 20mm larger than the short side of the curved back of the multi-layer board S, that is, 200mm; the upper part 7 of the bending mold and the lower part 9 of the bending mold are 600*200mm. Bending mold top 7 makes two through holes with a diameter of 35mm for fixing of the mould. The bending die upper part 7 and the bending die lower part 9 are installed on the cold press and wait for use. Then make the S-curved back of the multi-layer board. The specific steps are as follows: Step 1. The S-bent back of the multi-layer board with a specification of 500*180*25mm. After calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com