Method of reducing content of methyleugenol in rose essential oil

A technology of methyl eugenol and rose essential oil, which is applied in the direction of essential oil/perfume, fat production, etc., can solve the problem of high content of methyl eugenol in rose essential oil, achieve low cost of equipment, easy process control, and wide selection of dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

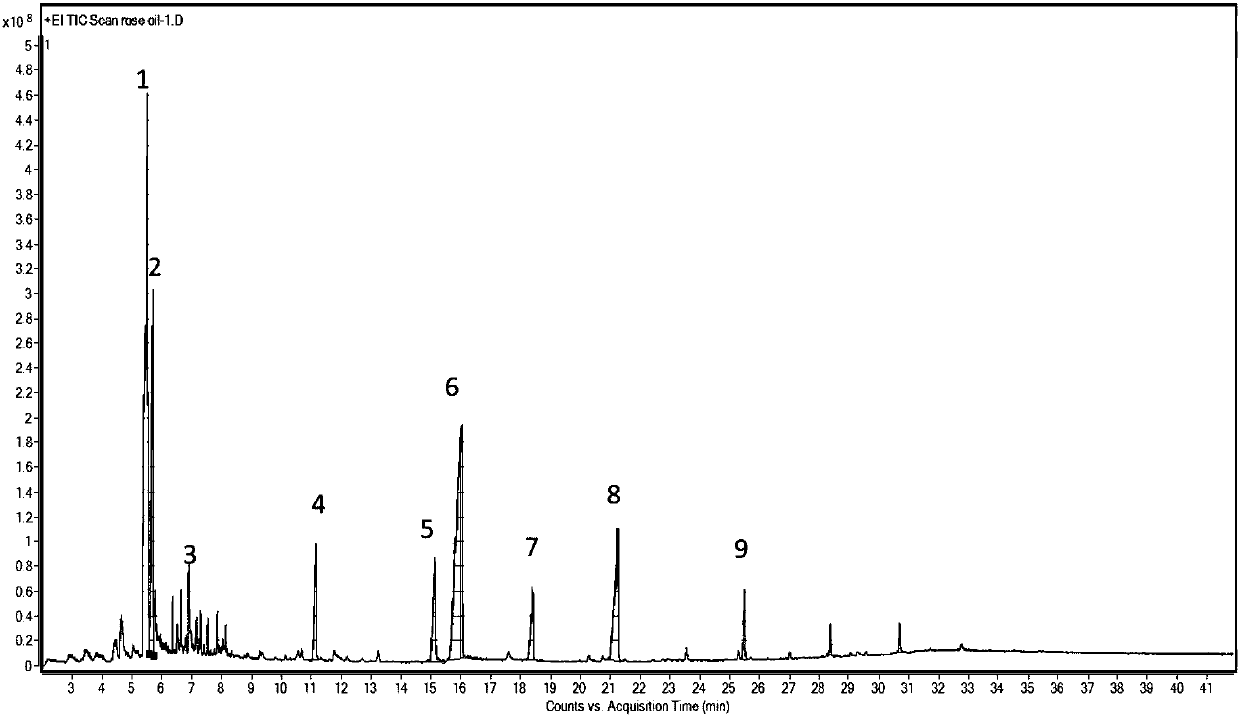

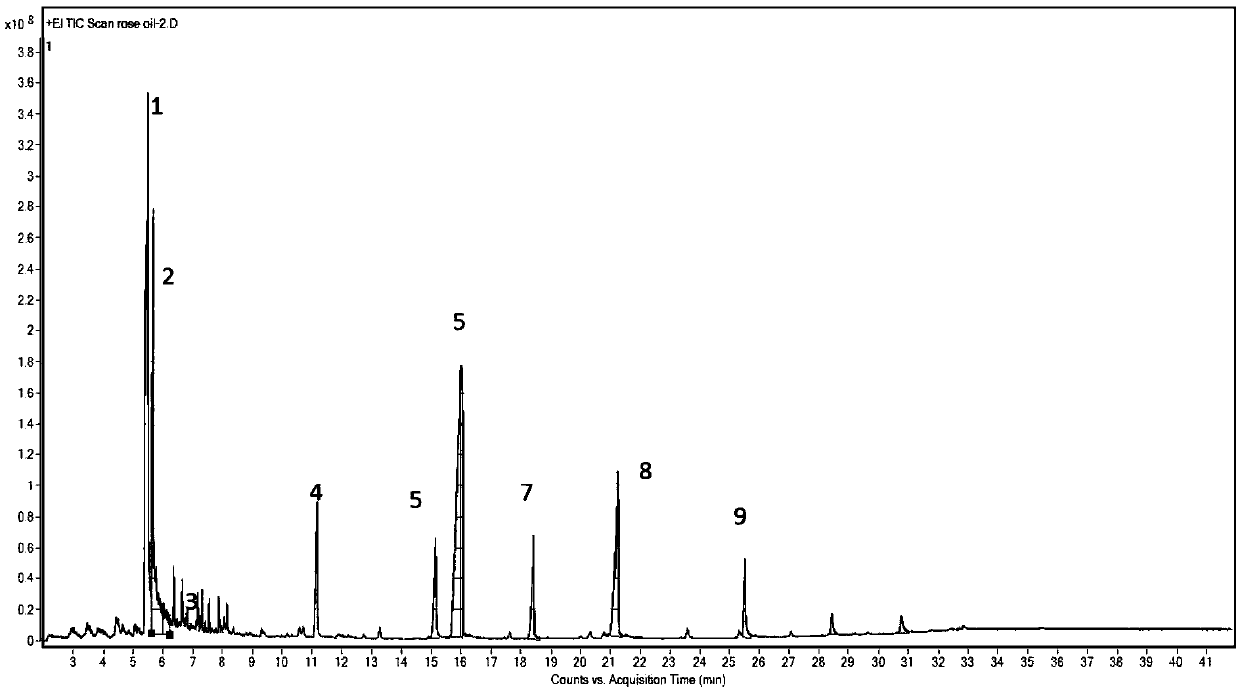

Image

Examples

Embodiment 1

[0039] Step 1: Accurately weigh 100.0g of rose essential oil raw material (methyl eugenol content 2.35%), add it to the molecular still, set the temperature at 50°C, preheat at 30°C, condense at 3°C, wiper speed at 300rpm, and distill The speed is 1g / min, and the evaporation pressure is 0.03MPa, until the rose essential oil is completely collected by the heavy component collection tank and the light component collection tank.

[0040] Step 2: Add the heavy component obtained in Step 1 as a raw material into the molecular still, set the distillation temperature to 85°C, the preheating temperature to 30°C, the condensation temperature to 3°C, the rotational speed to 300rpm, the distillation speed to 1g / min, and the evaporation pressure to 0.01MPa. Until the raw material is completely collected by the heavy component collection tank and the light component collection tank.

[0041] Step 3: Merge the light components in step 1 and the heavy components in step 2. After testing, the...

Embodiment 2

[0044]Step 1: Accurately weigh 100.0g of rose essential oil raw material (methyl eugenol content 2.35%), add it to the molecular still, set the temperature at 60°C, preheat at 30°C, condense at 3°C, wiper speed at 100rpm, and distill The speed is 3g / min, and the evaporation pressure is 0.02MPa, until the rose essential oil is completely collected by the heavy component collection tank and the light component collection tank.

[0045] Step 2: Add the heavy component obtained in Step 1 as a raw material into the molecular still, set the distillation temperature to 80°C, the preheating temperature to 30°C, the condensation temperature to 3°C, the rotational speed to 100rpm, the distillation speed to 1g / min, and the evaporation pressure to 0.01MPa. Until the raw material is completely collected by the heavy component collection tank and the light component collection tank.

[0046] Step 3: Merge the light components in step 1 and the heavy components in step 2. After testing, the ...

Embodiment 3

[0048] Step 1: Accurately weigh 100.0g of rose essential oil raw material (methyl eugenol content 2.35%), add it to the molecular still, set the distillation temperature to 70°C, the preheating temperature to 30°C, the condensation temperature to 3°C, and the film scraping speed to 400rpm, The distillation speed is 5g / min, and the evaporation pressure is 0.01MPa, until the rose essential oil is completely collected by the heavy component collection tank and the light component collection tank.

[0049] Step 2: Add the heavy component obtained in Step 1 as a raw material into the molecular still, set the distillation temperature to 90°C, the preheating temperature to 30°C, the condensation temperature to 3°C, the rotational speed to 400rpm, the distillation speed to 3g / min, and the evaporation pressure to 0.02MPa. Until the raw material is completely collected by the heavy component collection tank and the light component collection tank.

[0050] Step 3: combining the light co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com