Hole Forming Device, Hole Forming Method and Application for Ground Stress Test of Soil Formation

A technology of formation in-situ stress and hole-forming device, which is applied in the fields of on-site foundation soil survey, construction, and infrastructure engineering, etc., can solve the problems of inability to perform rapid in-situ stress test, the influence of test results is also great, and the influence of stress test results, etc. To achieve the effect of simple and reliable test method, accurate numerical calculation results of soil stratum, and high construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

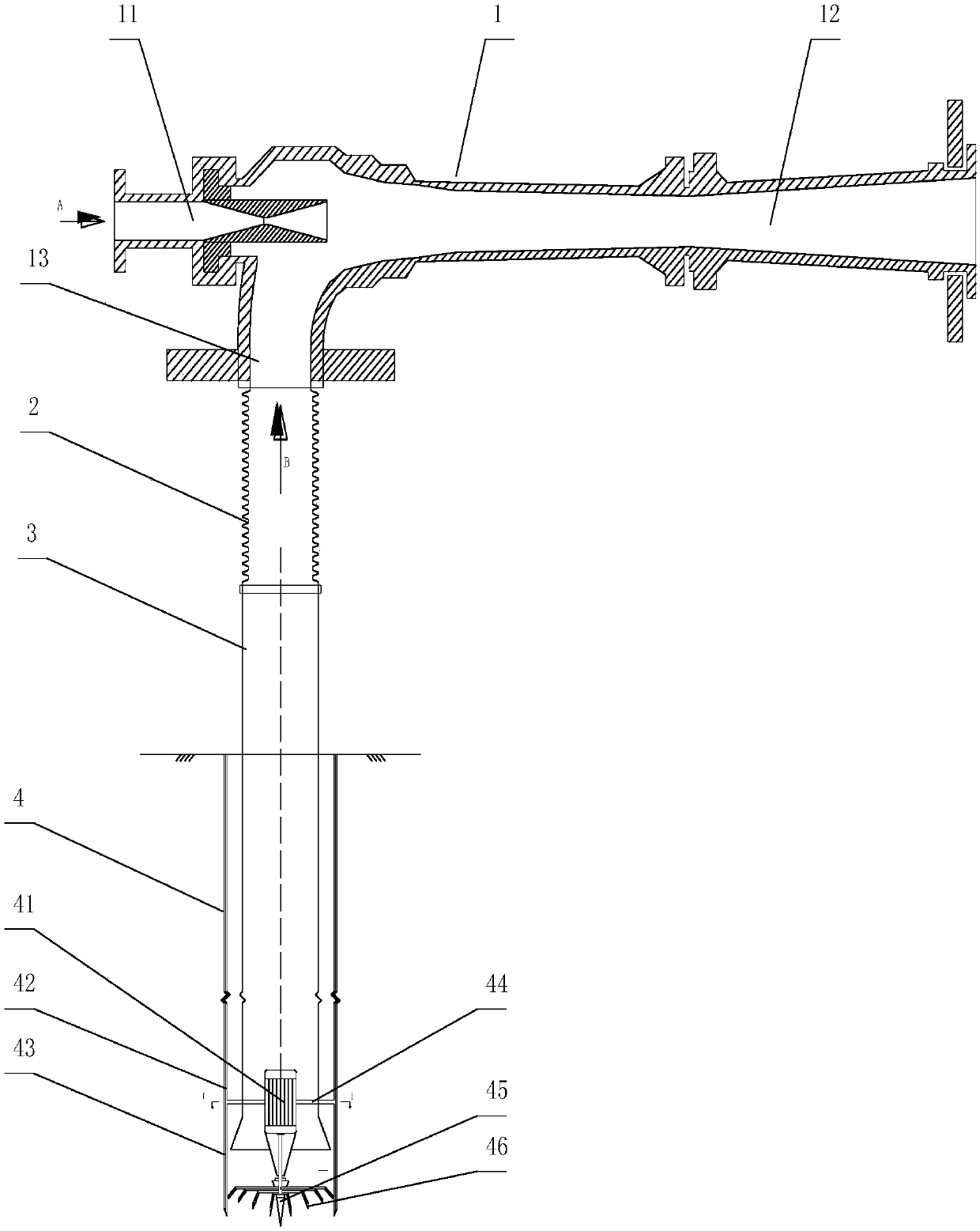

Embodiment 1

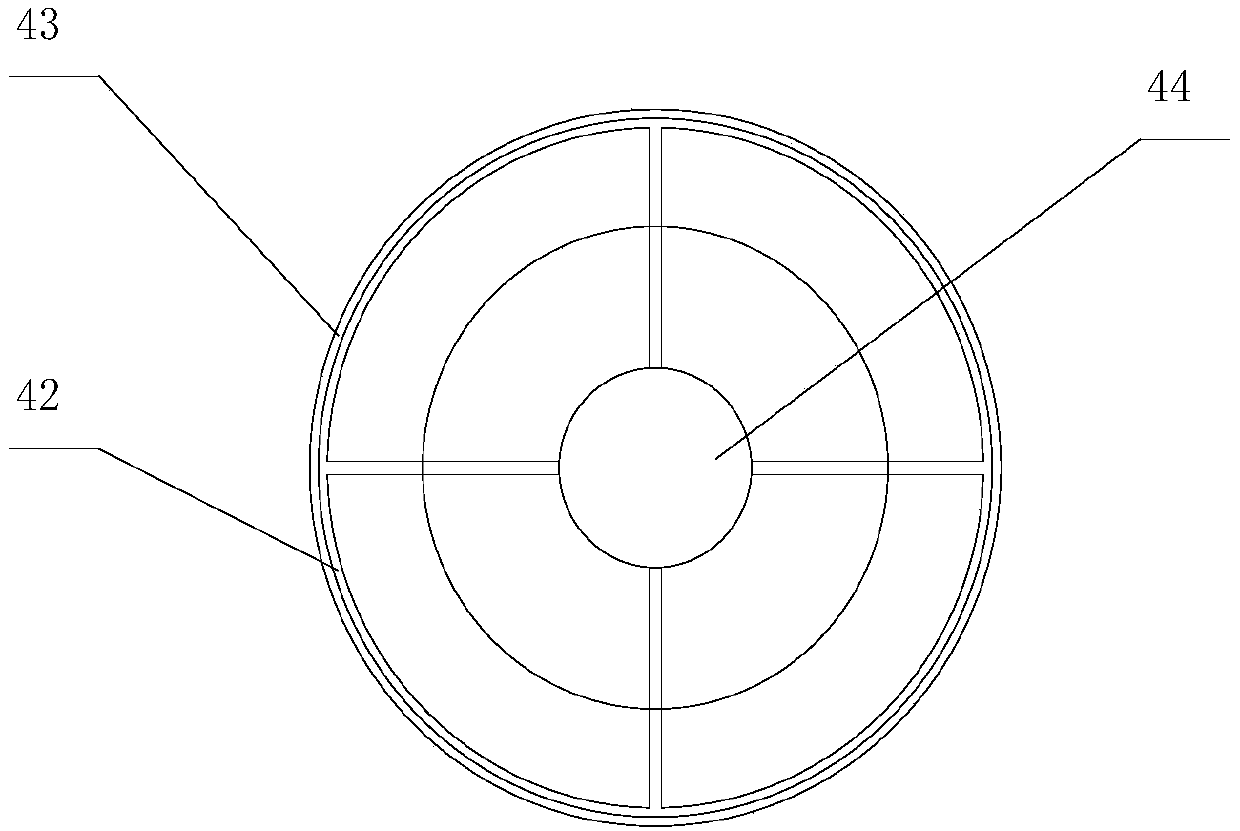

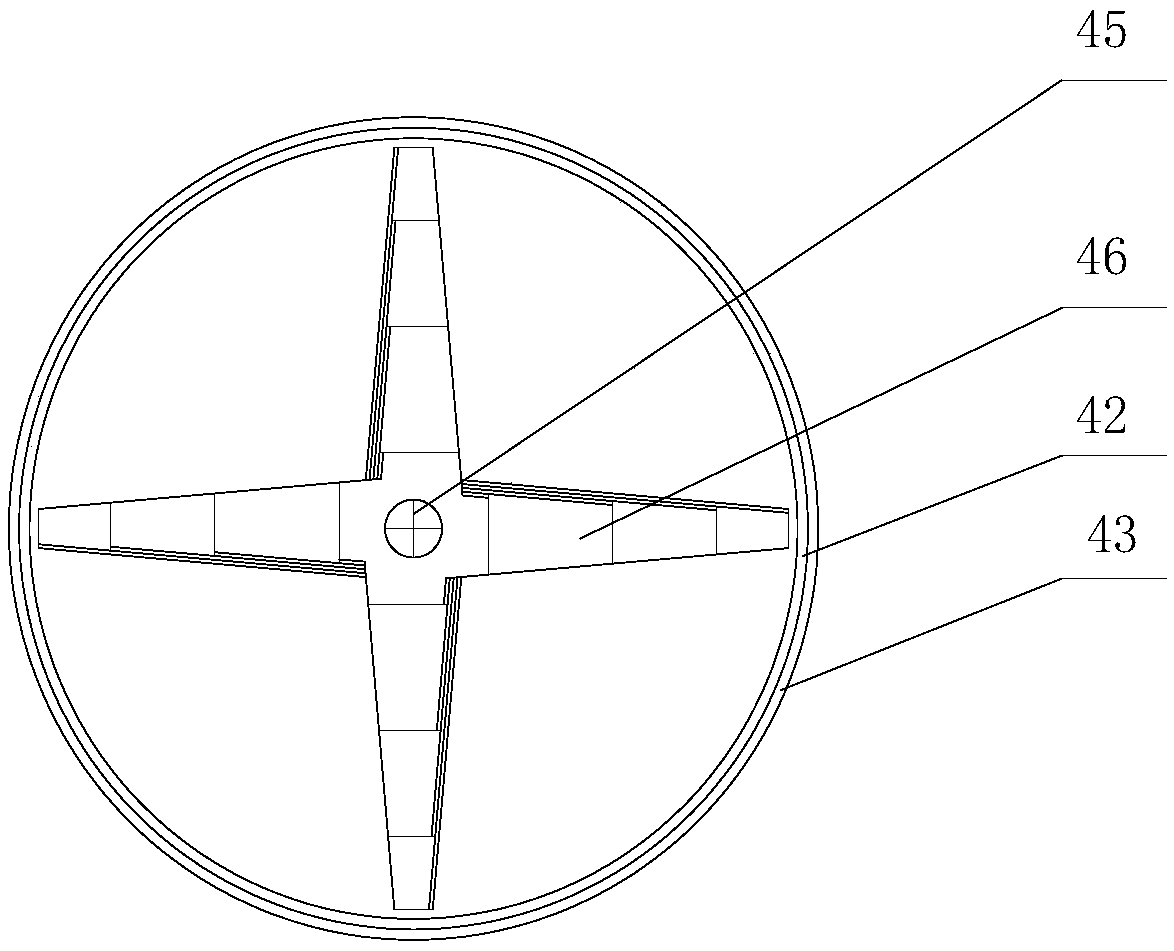

[0045] The hole diameter of present embodiment is 40cm, and the internal diameter of outer layer protective shell 43 is 40cm, and the inner diameter of inner layer protective shell 42 is 39cm, and the blade foot angle of inner and outer layer protective shell 43 is 30 °. The central pyramid cutter 45 adopts a quadrangular pyramid structure, and the U-shaped cutter group is set around the central pyramid cutter 45. It includes 4 U-shaped cutter groups with different spans. The U-shaped cutters arranged in pattern form, the single U-shaped cutter 46 of the first group of U-shaped cutters has a horizontal span of 9cm, the bending angle of the blade is 100°, and the single U-shaped cutter of the second group of U-shaped cutters Type cutter 46 horizontal span is 18cm, the bending angle of blade is 110 °, the single U-shaped cutter 46 horizontal span of the third group of U-shaped cutter group is 27cm, the bending angle of blade is 120 °, the fourth group The single U-shaped cutter ...

Embodiment 2

[0047] The hole diameter of present embodiment is 10cm, and the inner diameter of outer layer protective shell 43 is 10cm, and the inner diameter of inner layer protective shell 42 is 8cm, and the blade foot angle of inner and outer layer protective shell 43 is 24 °. The central pyramid cutter 45 adopts a quadrangular pyramid structure, and the U-shaped cutter group is set around the central pyramid cutter 45. It includes 2 sets of U-shaped cutter groups with different spans. The uniform U-shaped cutters are composed of uniformly distributed U-shaped cutters. The single U-shaped cutter 46 of the first group of U-shaped cutters has a horizontal span of 5cm and the bending angle of the blade is 100°. The single U-shaped cutter of the second U-shaped cutter group Type cutter 46 horizontal spans are 7cm, the bending angle of blade is 120 °, promptly the cutting diameter of first U-shaped cutter group is 5cm, and the cutting diameter of second U-shaped cutter group is 7cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com