Flow guiding type ore drawing pond field and ore drawing method thereof

A technology for mining pools and mine openings, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as uneven slurry coverage and excessive slope, to protect sand and soil loss, reduce engineering workload, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

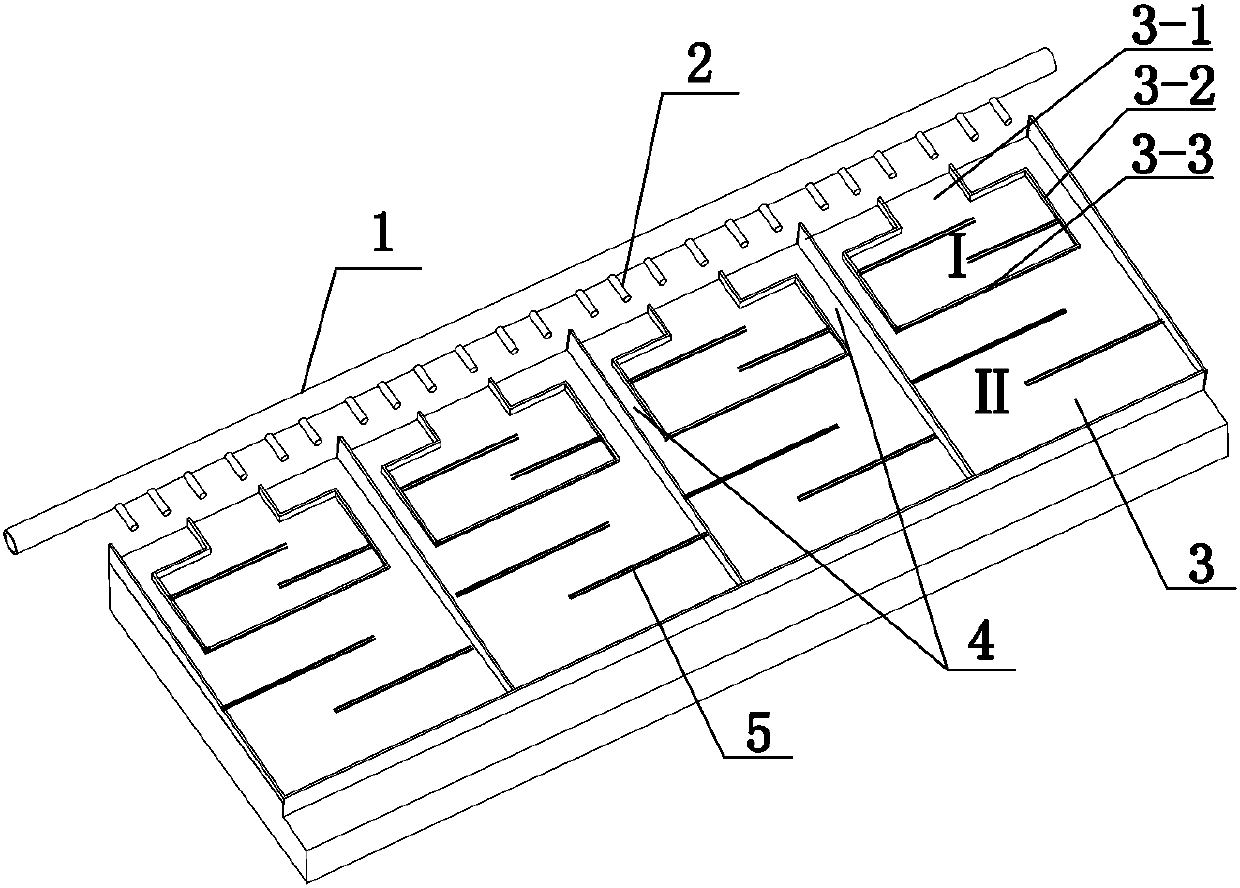

[0027] Such as figure 1 As shown, a diversion type ore-drawing pool field of the present invention is characterized in that: several groups of ore-drawing pool fields 3 are made on the dry beach surface of the tailings pond along the direction of the dam, and the ore-drawing main pipeline 1 laid at the tailings pond ring dam is A plurality of ore-drawing branch pipes 2 are arranged on the top, and each group of ore-drawing pools 3 is composed of more than two ore-drawing pools;

[0028] Described ore-drawing pool is made up of pool wall 3-2, partition dam 3-3 and ore-drawing port 3-1, and each ore-drawing port 3-1 corresponds to more than one ore-drawing branch pipe 2, and in each ore-drawing pool Diversion dam ridges 5 are also staggered inside.

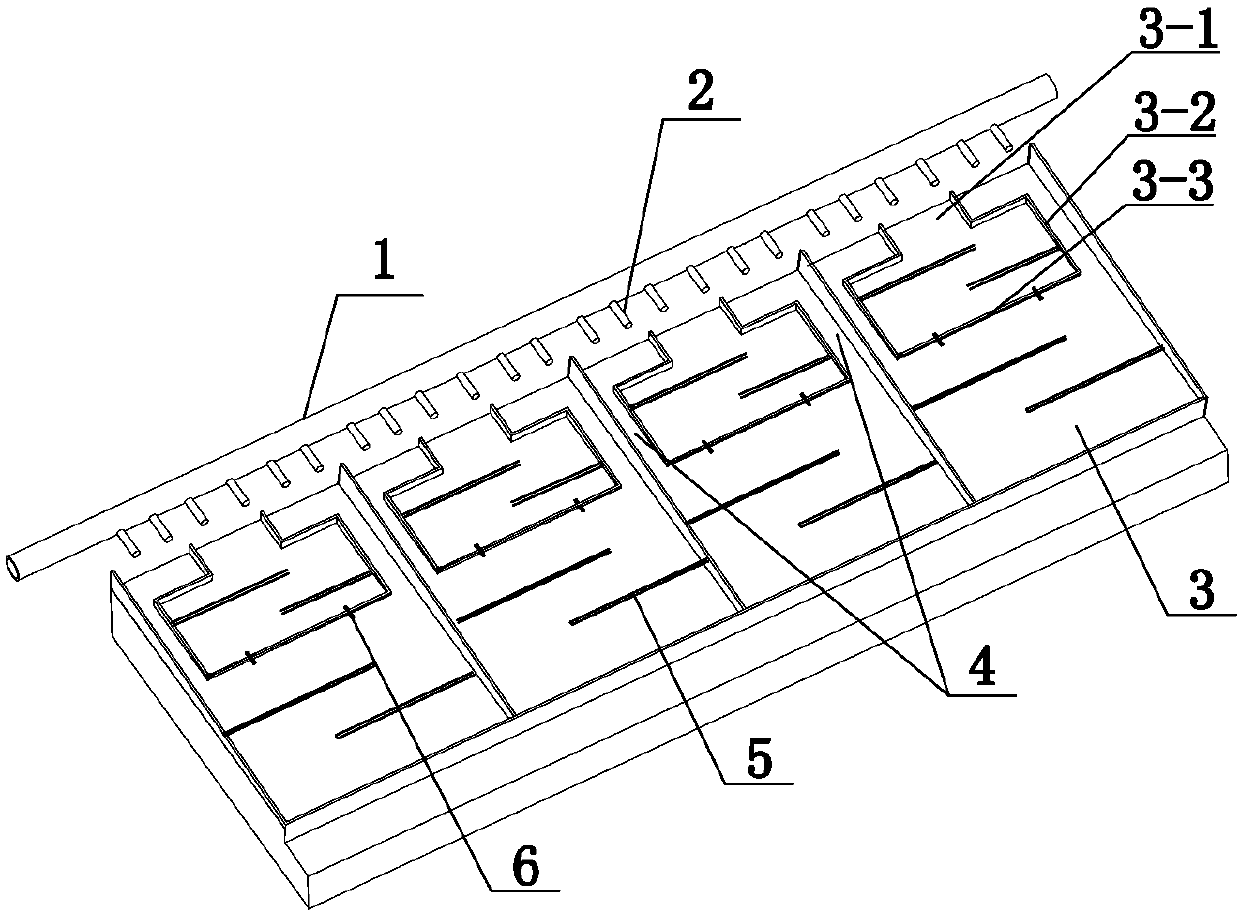

[0029] Such as figure 2 As shown, two or three overflow pipes 6 are evenly distributed on the partition dam 3-3 of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com