Tunnel construction trolley

A technology of tunnel construction and trolley, which is applied in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of inability to guarantee safety, time-consuming and labor-intensive, and high labor costs, and achieve the effects of reducing mechanical failure rate, convenient pulping, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

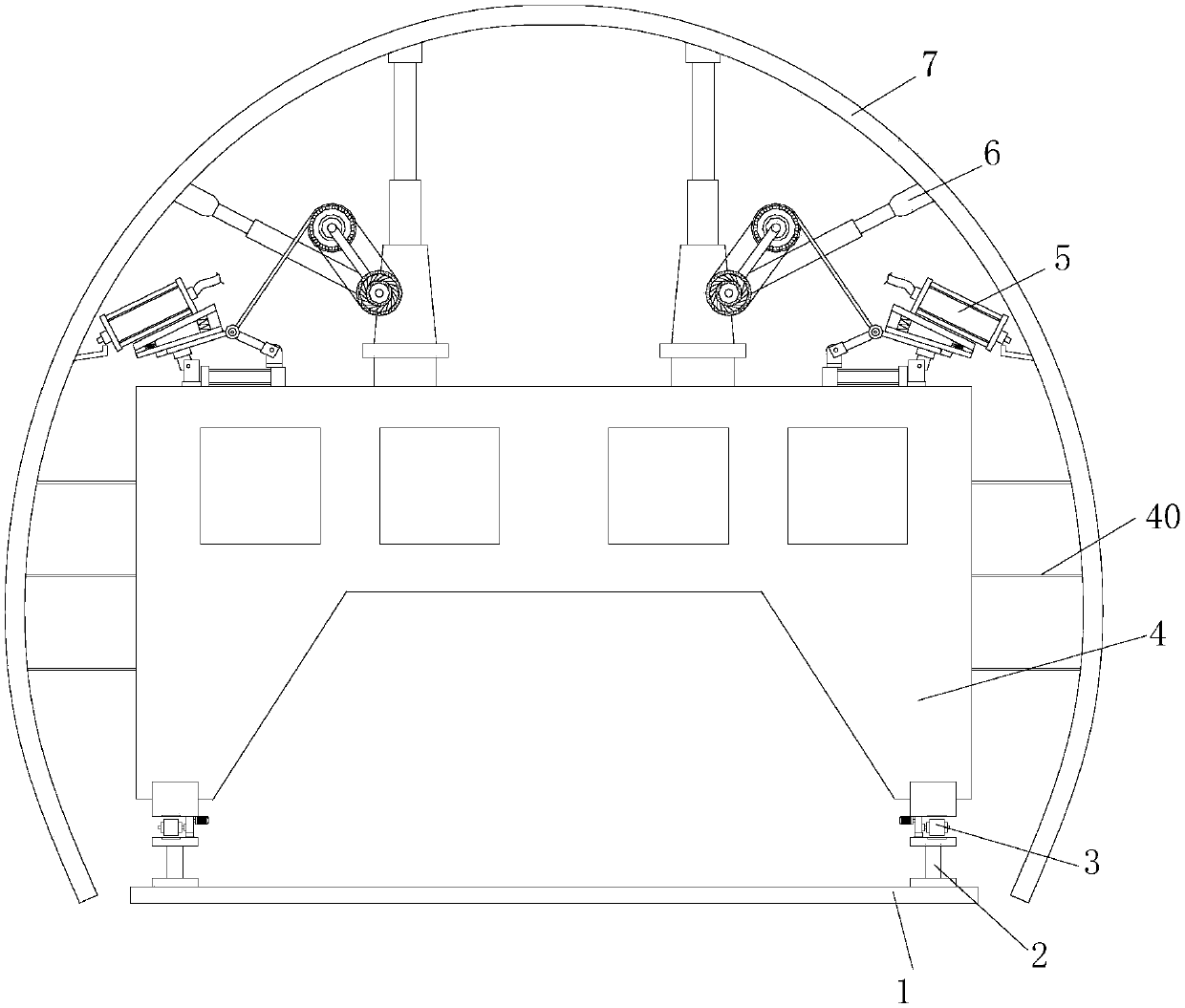

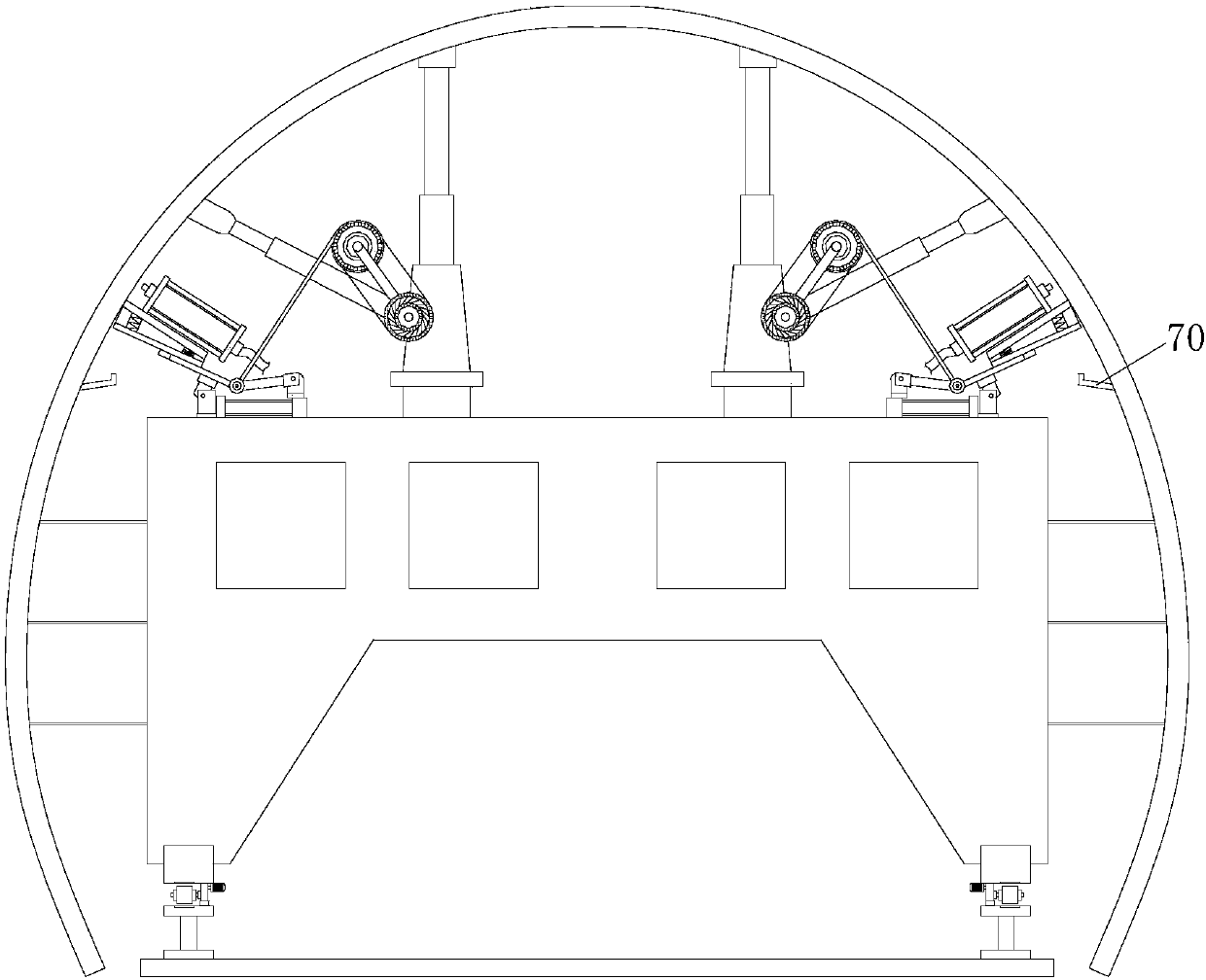

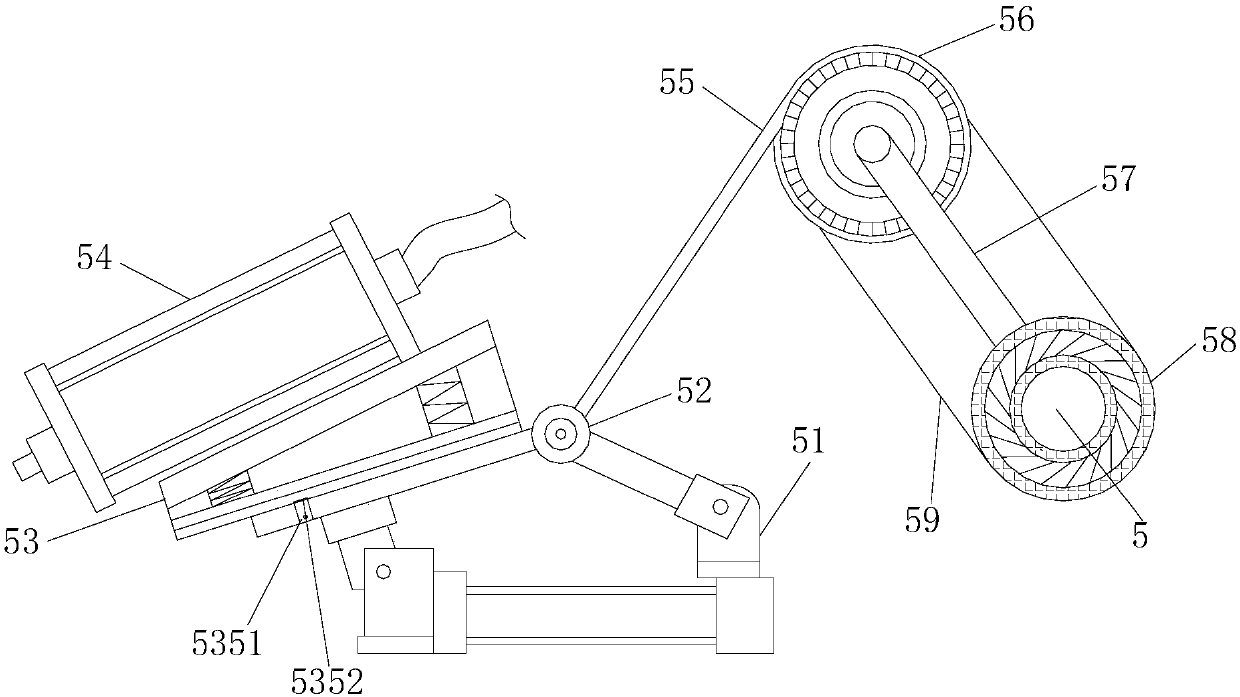

[0021] see Figure 1-Figure 4, the present invention provides a tunnel construction trolley: its structure includes a tunnel construction trolley, its structure includes a sleeper 1, a track 2, a traveling wheel 3, a door frame 4, a linkage mechanism 5, a jack 6, and an outer membrane plate 7 , the track 2 that is provided with a pair is an I-shaped structure, the upper surface of the two ends of the sleeper 1 is respectively welded with a track 2, and the traveling machine wheel 3 is provided with a pair that is respectively located between the track 2 and the door frame 4, and the three meshing, the track 2 and the door frame 4 are lifted and connected by the traveling machine wheel 3, and the door frame 4 is provided with more than three arched structures, and the two sides of the door frame 4 are connected with the inner surface of the outer membrane plate 7 through The welding rod 40 is fixedly connected, the connecting welding rod 40 is provided with two rows, and each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com