Indoor gas pipeline leakage detection method

A technology for pipeline leakage and detection methods, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as low reliability, danger, and difficult sensing, and achieve novel structure, high reliability, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

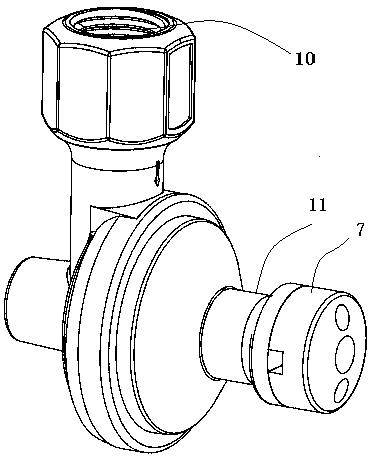

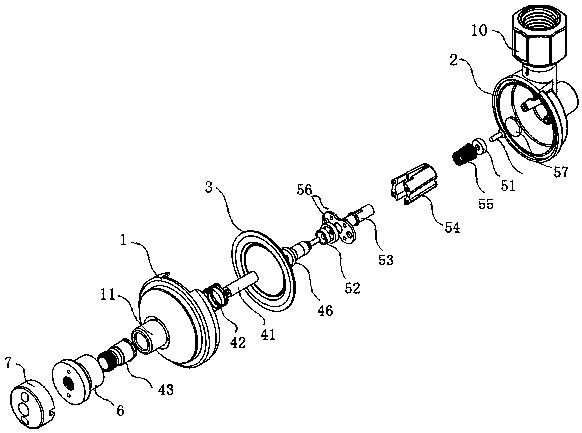

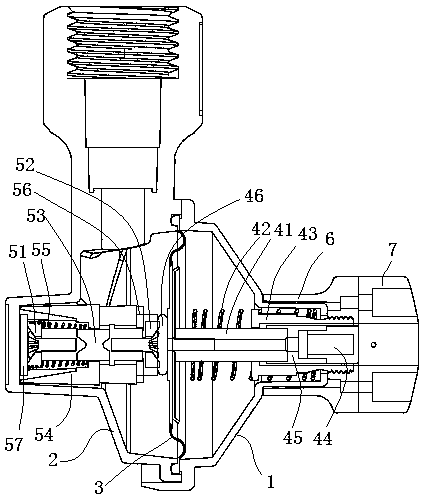

Image

Examples

Embodiment Construction

[0023] In order to make it easier for those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with specific examples.

[0024] The gas pipeline leakage detection method described in the present invention is to install a pressure sensing device in the gas pipeline; monitor the gas by detecting the gas pressure in the pipeline, and trigger a signal alarm when the gas pressure is abnormal. When the pipeline is normal and there is no leakage, the gas pressure in the pipeline should be basically stable. When there is a leakage, the pressure in the pipeline will be relatively low. At this time, the pressure change can be monitored by using the pressure sensing device, and an alarm is given.

[0025] The pressure sensing device is generally installed in the user's indoor pipeline, and its normal use range is set. When testing, the corresponding household main valve is closed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com