Novel fan exhaust gas recirculation type turbocharging range hood

A range hood and fan technology, which is applied in the field of kitchen appliances, can solve the problems of different pressures, short pipeline lengths, exhaust backflow cannot be solved well, and achieve the effects of reducing weight, volume, and oil fume deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

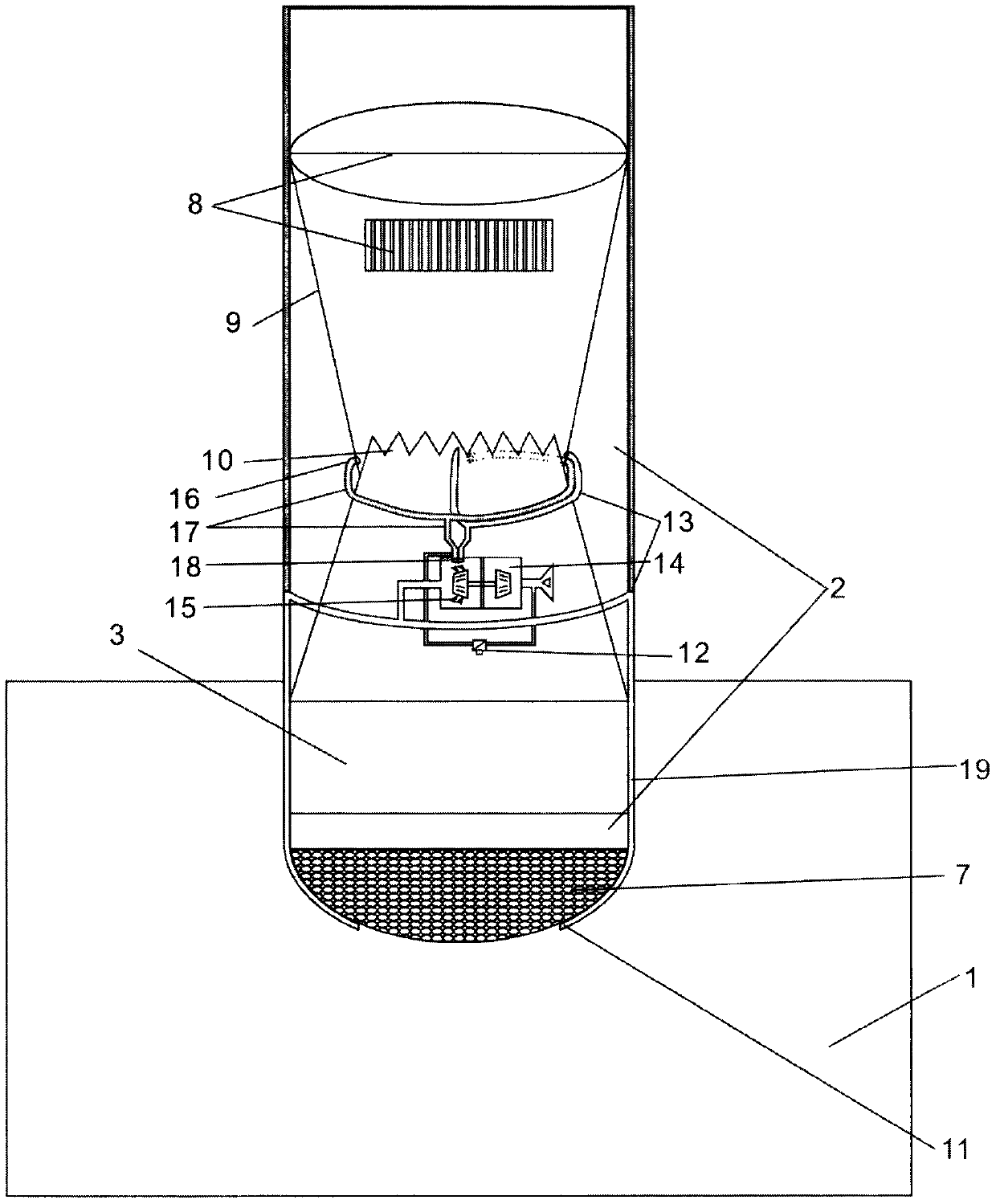

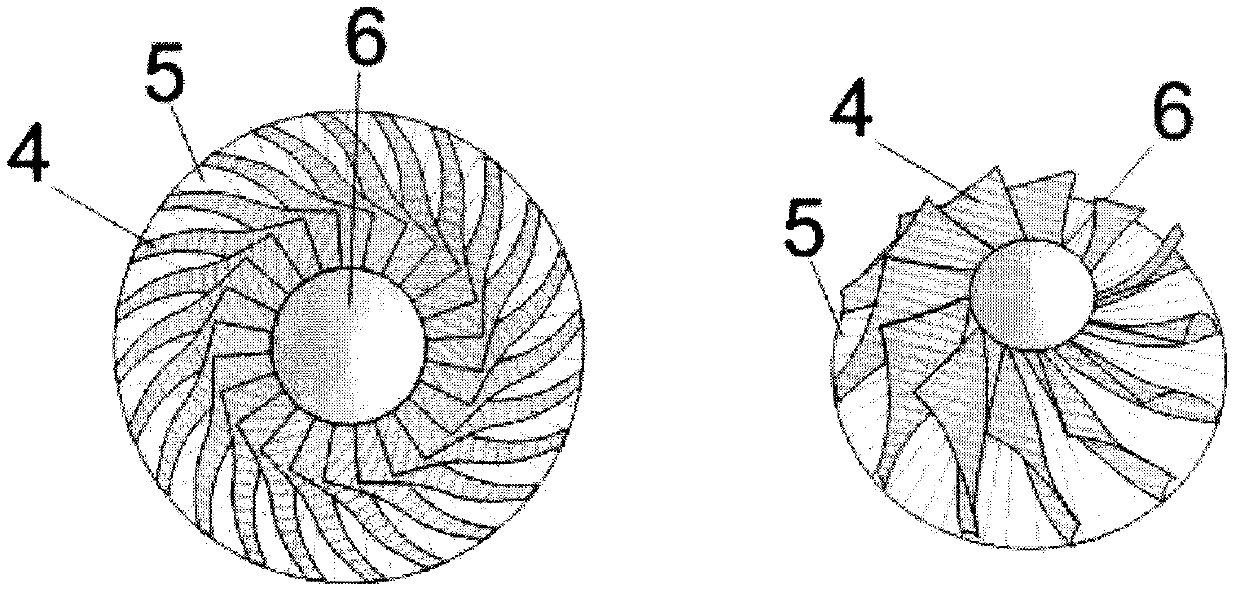

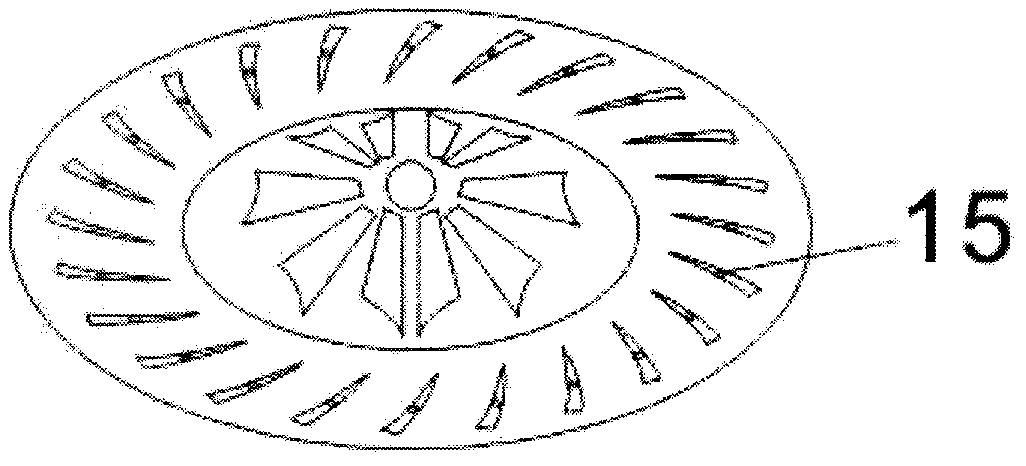

[0030] refer to figure 1 As shown, a range hood of the present invention includes a range hood body 1, an axial flow fan with adjustable blades, a mixed flow (diagonal flow) booster fan instead of a centrifugal fan 2, the fans can also be connected in parallel or in series, and the speed can be adjusted 3 , straight-through air duct and hemispherical, double arc-shaped plasma electrostatic blades 7, openable valves and indoor air outlets that can be linked 8, Venturi principle air intake, air outlet flue 9, exhaust port shrinkage tail The edge is serrated 10, the exhaust gas recirculation pipeline 11, the EGR control valve 12, the Venturi tube EGR system 13, the exhaust gas circulation system with mechanical and turbocharging devices 14, and the holes on the exhaust pipe are used for oil fume The pipeline 16, 4-2-1 exhaust pipe 17, single turbine and twin-scroll pipe 18 of the exhaust cycle of the machine, and the integrated pipeline 19 of the casing cavity of the hood all bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com