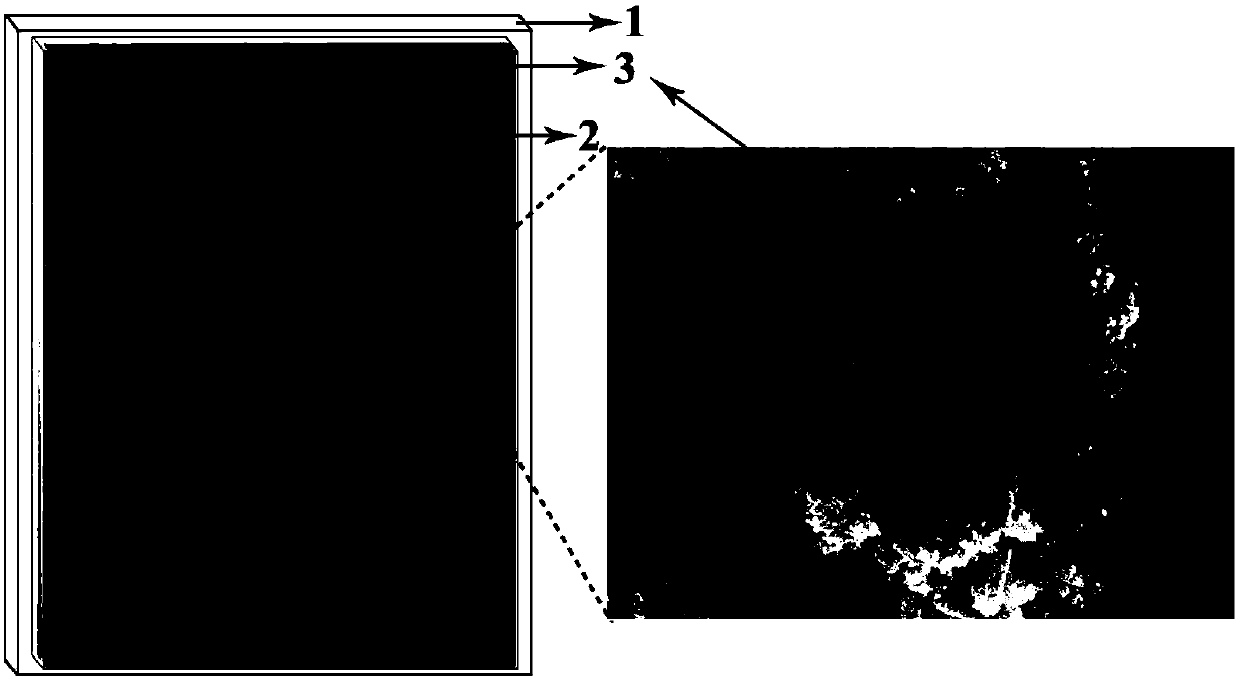

Flexible plane-type NH3 gas sensor based on PANI (at) flower-like WO3 nanoscale sensitive material and application thereof

A gas sensor and sensitive material technology, applied in nanotechnology for sensing, nanotechnology for materials and surface science, material resistance, etc., can solve problems such as increased operating temperature and energy consumption limitations, and achieve reliability Strong, simple method, simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

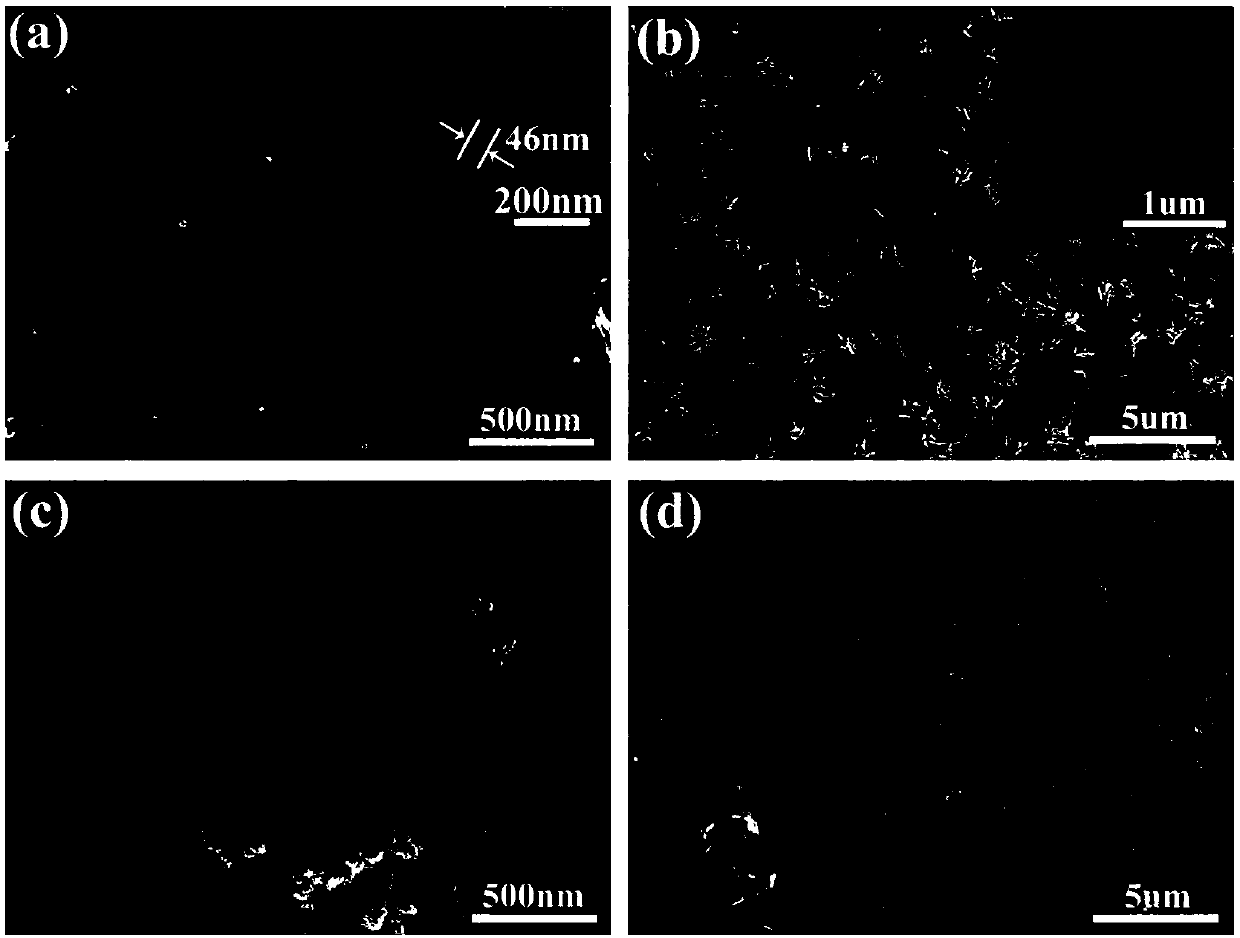

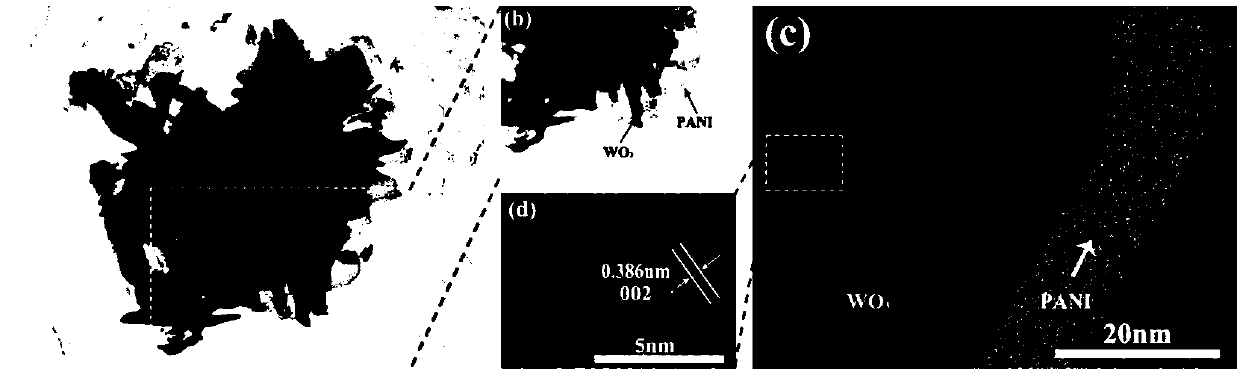

Embodiment 1

[0055] With PANI@2mol.% flower-like WO 3 Making NH as a nanosensitive material 3 The sensor, its manufacturing process is:

[0056] In PANI@2mol.% flower-like WO 3 Making NH as a nanosensitive material 3 Add 2.3 mg of the flower-like WO prepared in Comparative Example 1 during the in-situ polymerization of the sensor 3 Nano-sensitive materials, and the rest of the device manufacturing process is the same as that of Comparative Example 2, which is marked as sensor PAW2.

Embodiment 2

[0058] With PANI@5mol.% flower-like WO 3 Making NH as a nanosensitive material 3 The sensor, its manufacturing process is:

[0059] In PANI@5mol.% flower-like WO 3 Making NH as a nanosensitive material 3 Add 5.8 mg of the flower-shaped WO prepared in Comparative Example 1 during the in-situ polymerization of the sensor3 Nano-sensitive materials, and the rest of the device manufacturing process is the same as that of Comparative Example 2, which is marked as sensor PAW5.

Embodiment 3

[0061] With PANI@10mol.% flower-like WO 3 Making NH as a nanosensitive material 3 The sensor, its manufacturing process is:

[0062] In PANI@10mol.% flower-like WO 3 Making NH as a nanosensitive material 3 Add 11.6 mg of the flower-shaped WO prepared in Comparative Example 1 during the in-situ polymerization of the sensor 3 Nano-sensitive materials, and the rest of the device manufacturing process is the same as that of Comparative Example 2, which is marked as sensor PAW10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com