Screen miss-coating glass passivation mold and technique

A glass passivation and wire mesh technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of affecting the lithography process, large glass stress, expensive equipment, etc., to improve the voltage breakdown characteristics, The effect of reducing glass stress and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

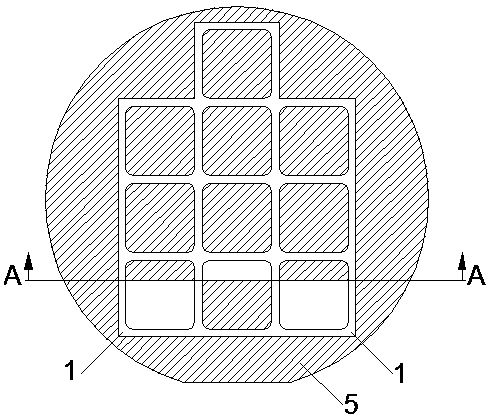

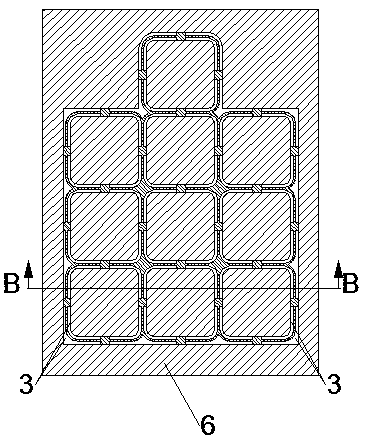

[0027] Such as Figure 1-9 Shown, a kind of passivation mold of silk screen leak-coated glass comprises: silicon single chip 5, stainless steel wire mesh screen plate 6, stainless steel scraper 7, silicon single chip 5 is provided with mesa corrosion tank 1, stainless steel wire mesh screen plate 6 bands There are bosses 2 and leakage areas 3, and one side of the stainless steel screen plate 6 is provided with bosses 2. The arrangement, position, shape and size of the leakage areas 3 are exactly the same as those of the mesa etching groove 1 area on one side of the silicon single wafer 5. Consistent, the adjacent positions on both sides of the boss 2 are provided with a leakage area 3, and one side of the stainless steel scraper 7 is provided with a 2-5CM high blade 4.

[0028] The protruding height of the boss 2 is 3-5 microns shorter than the depth of the etching groove 1 on the mesa 5 of the silicon single wafer 5 .

[0029] The silicon single wafer 5 is circular, with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com