Method for manufacturing branch pipe and branch connection device for hose connection and fuel supply hose manufactured thereby

A hose connection and manufacturing method technology, which is applied in the field of hoses with bending or twisting phenomena, can solve the problems of gas or oxygen leakage from branch connection appliances, and the inability to perform operations with peace of mind, so as to prevent safety accidents and facilitate maintenance , the effect of strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

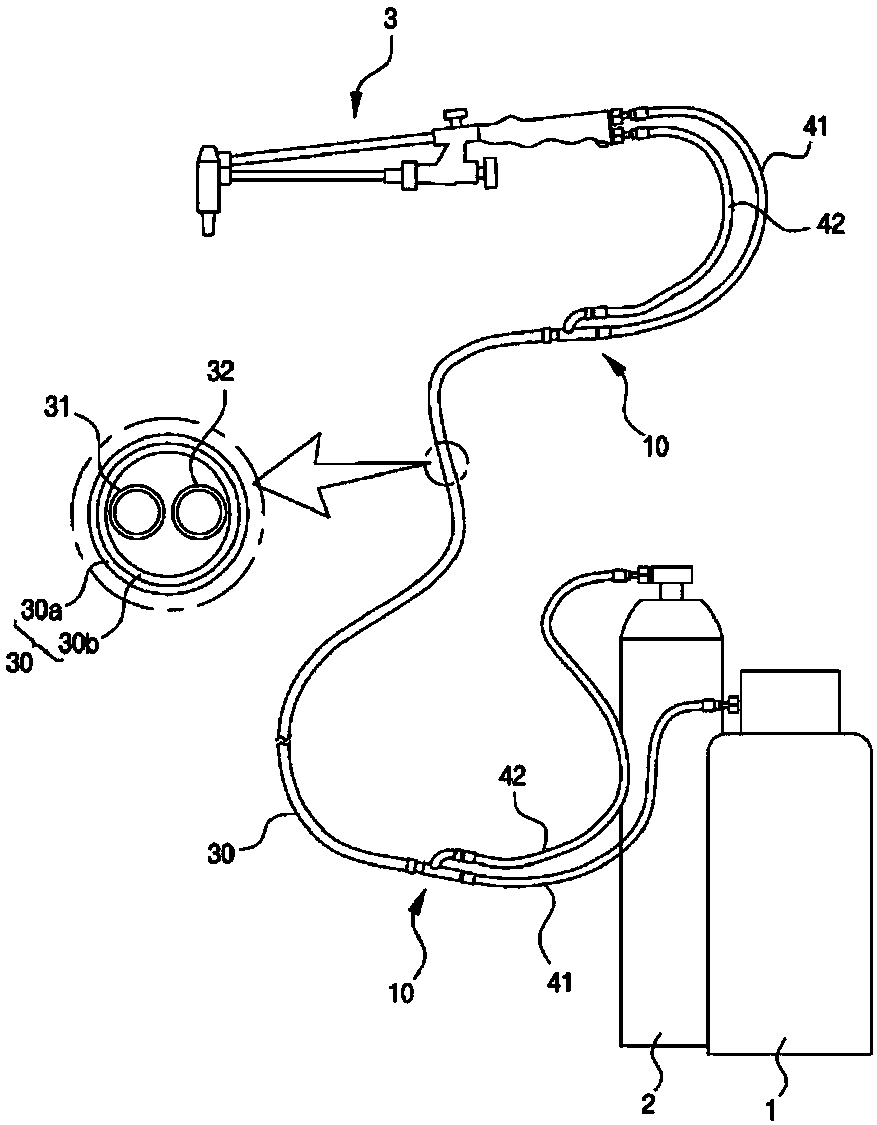

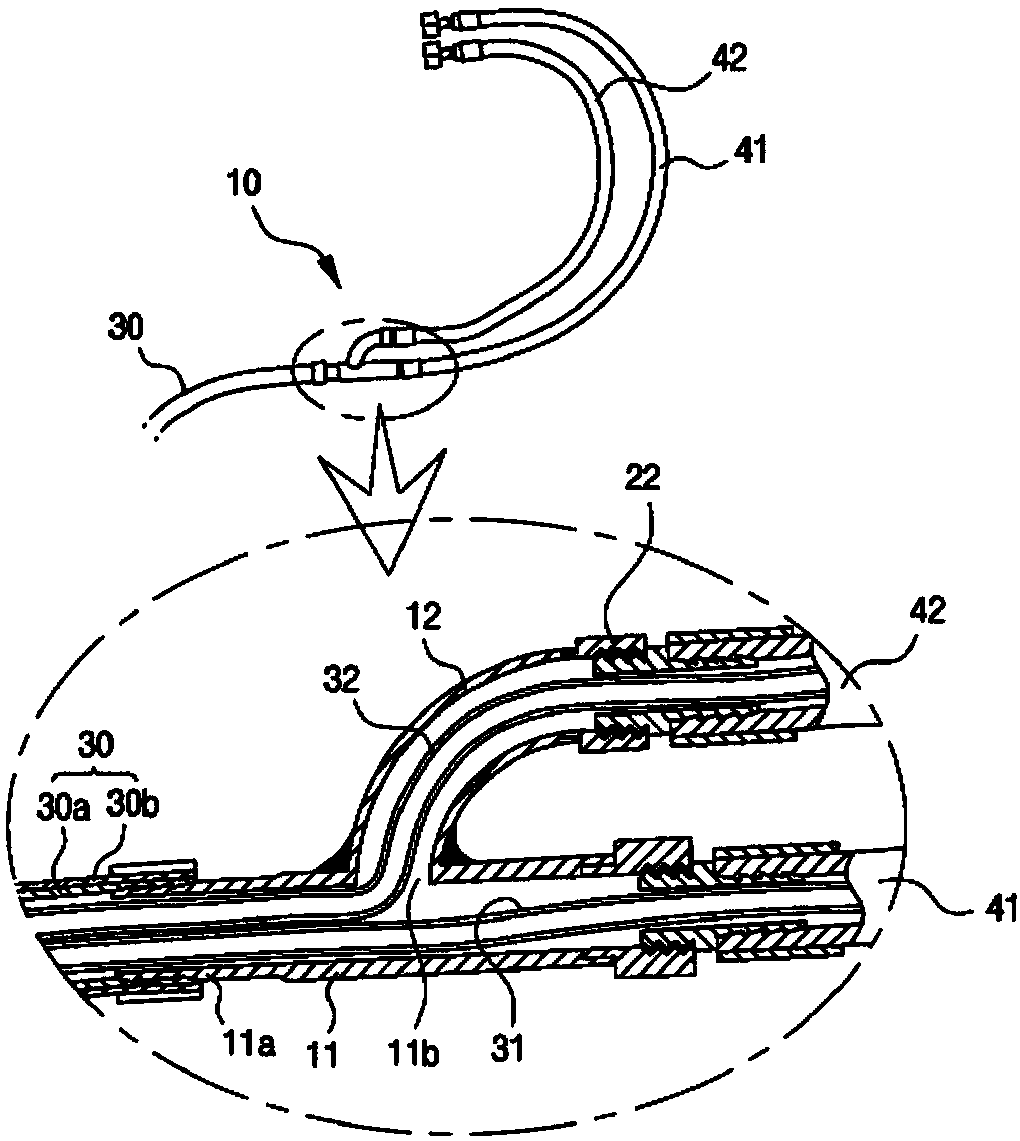

[0045] Hereinafter, an embodiment of the present invention for achieving the object described in the problem to be solved will be described in detail with reference to the drawings. It should be understood that an embodiment described below is used as an example to help understand the present invention, and that the present invention can be implemented in various modifications different from the embodiment described here. However, when describing the present invention, if it is judged that the specific description of related known functions or structural elements is unnecessary and confounds the gist of the present invention, the specific description and specific display are omitted. In addition, for the convenience of understanding the invention, the drawings are not shown on an actual scale, but are exaggerated to show the size of some structural elements.

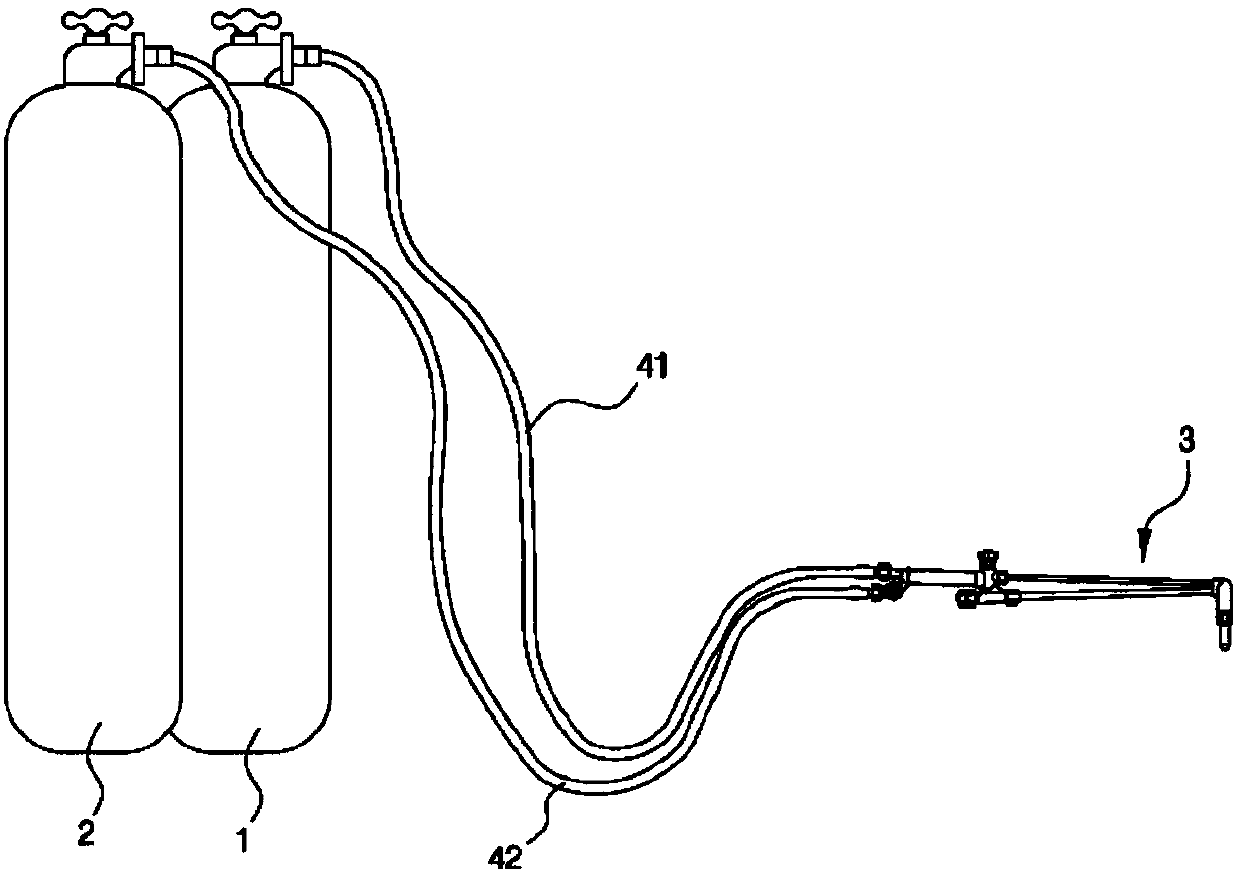

[0046] The present invention relates to a method for manufacturing a branch pipe for hose connection and a branch connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com