Device for coal powder injection of blast furnace

A blast furnace and pulverized coal technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as pulverized coal injection and pulsation, and achieve the effects of uniform pulverized coal transportation, improved combustion rate, and uniform time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

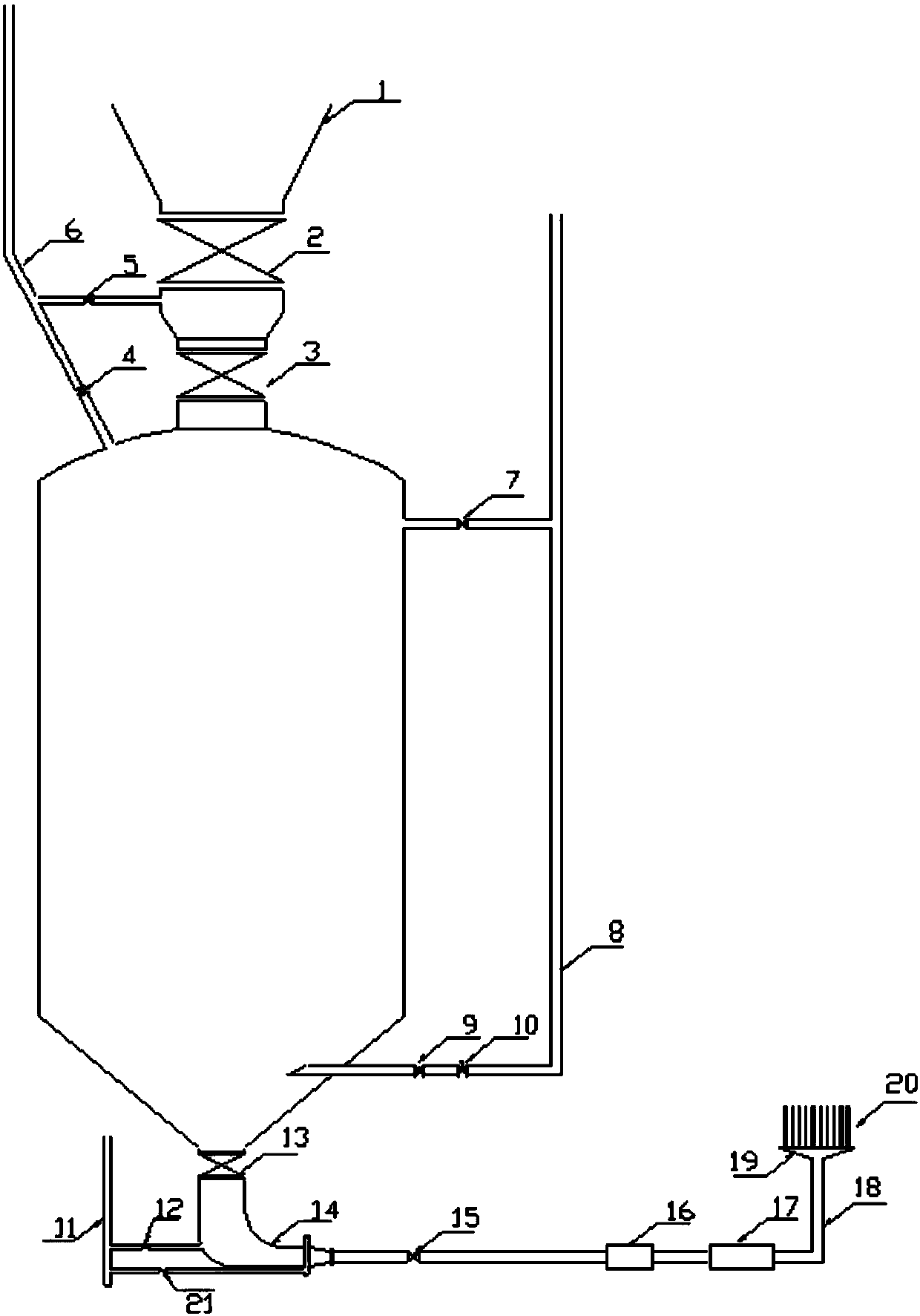

[0037] figure 1 It is a schematic structural diagram of a device for injecting pulverized coal into a blast furnace provided in an embodiment of the present application. Such as figure 1 As shown, the blast furnace is connected with a blow tank, and the device includes:

[0038] The first nitrogen pipeline 8 is arranged at a first position on the bottom of the spray tank.

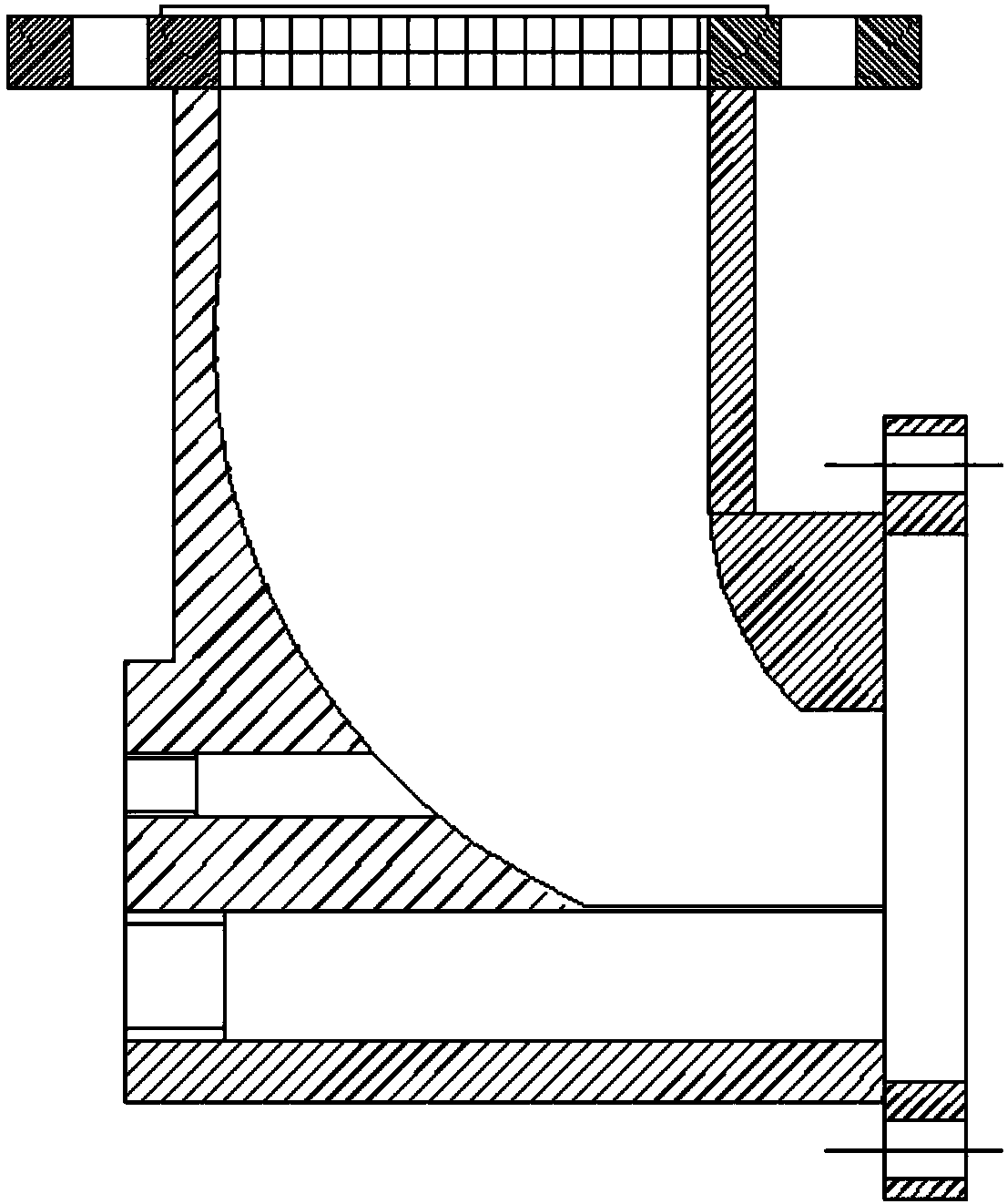

[0039]Further, the conduit of the first nitrogen pipeline 8 at the inner part of the spray tank has a chamfered surface, and the chamfered surface faces the top of the spray tank.

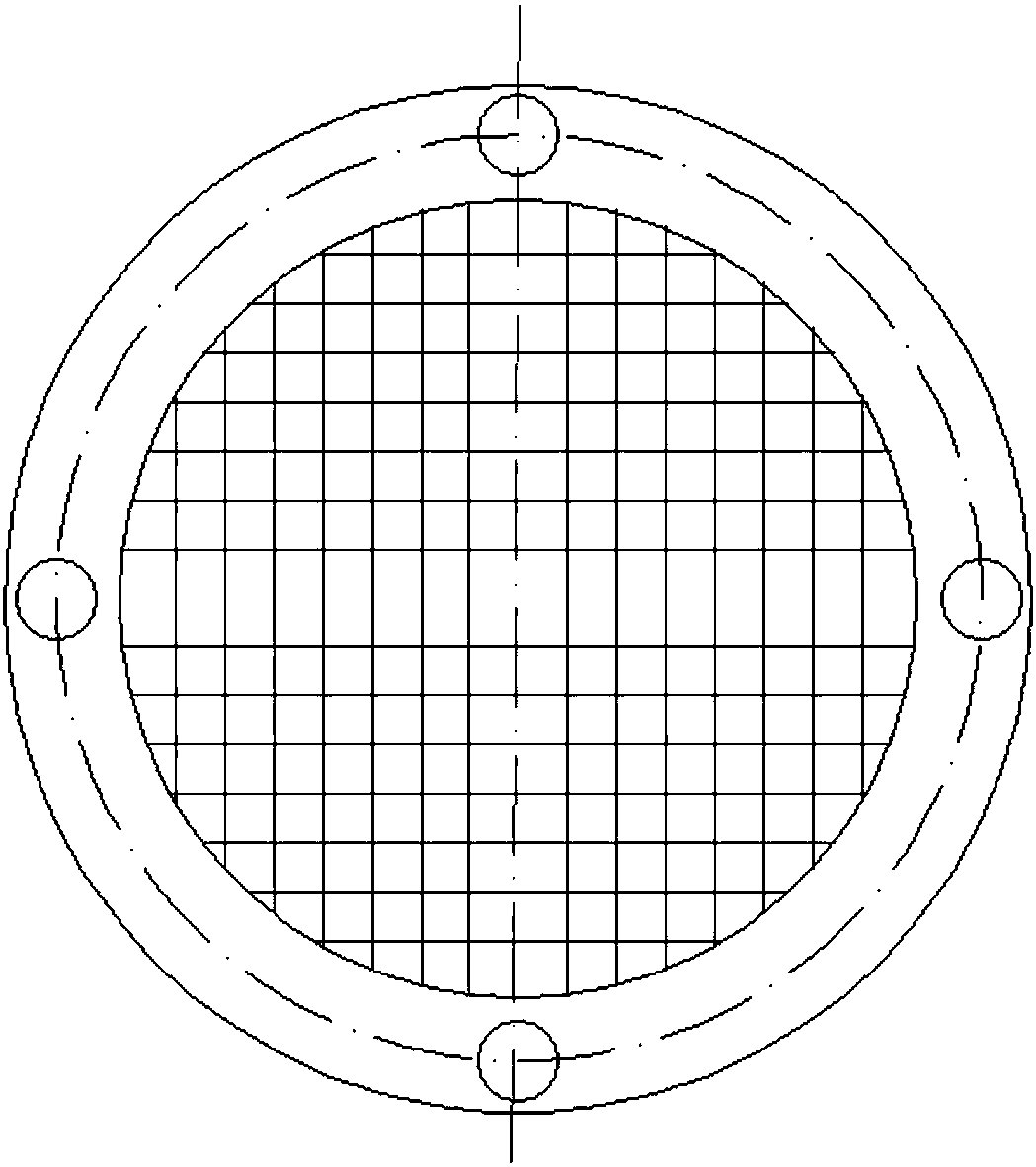

[0040] Specifically, the first nitrogen pipeline 8 is arranged at a first position on the bottom of the spray tank, and the pipeline of the first nitrogen pipeline 8 is in the shape of a right angle. The first regulating valve 10 and the pneumatic ball valve 9 are provided, and the pressure of the pipeline can be adjusted through the charging valve 7, and the first nitrogen pipeline 8 goes deep into the inner part of the blow...

Embodiment 2

[0061] The operating principle of a kind of blast furnace pulverized coal injection device of the present invention is described in detail below, specifically as follows:

[0062] The process flow of the device includes: normally open fluidized blowing tank → first mixer with filter → second mixer for supplementing gas in proportion → dual-purpose filter for gas back blowing and manual cleaning → high precision Distributor→branch pipe of equal length→spray gun adjusted in real time.

[0063] When the blast furnace starts coal injection, adjust the opening degree of the first regulating valve 10 in time, and keep the pneumatic ball valve 9 in a normally open state through adjustment, and the gas continuously enters the injection tank as the injection process progresses. Due to the difference in the amount of coal injected into the blast furnace, the opening of the pneumatic ball valve 9 in the injection tank will be different, and the automatic adjustment can be realized throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com