Round steel for major diameter engineering machine hydraulic oil cylinder piston rod and manufacturing method of round steel

A technology for construction machinery and hydraulic cylinders is applied in the field of large-diameter round steel for the piston rod of construction machinery hydraulic cylinders and its continuous casting, which can solve the problems of low production efficiency and high production cost of round steel, achieve small center segregation, and improve mechanics. The effect of satisfying performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

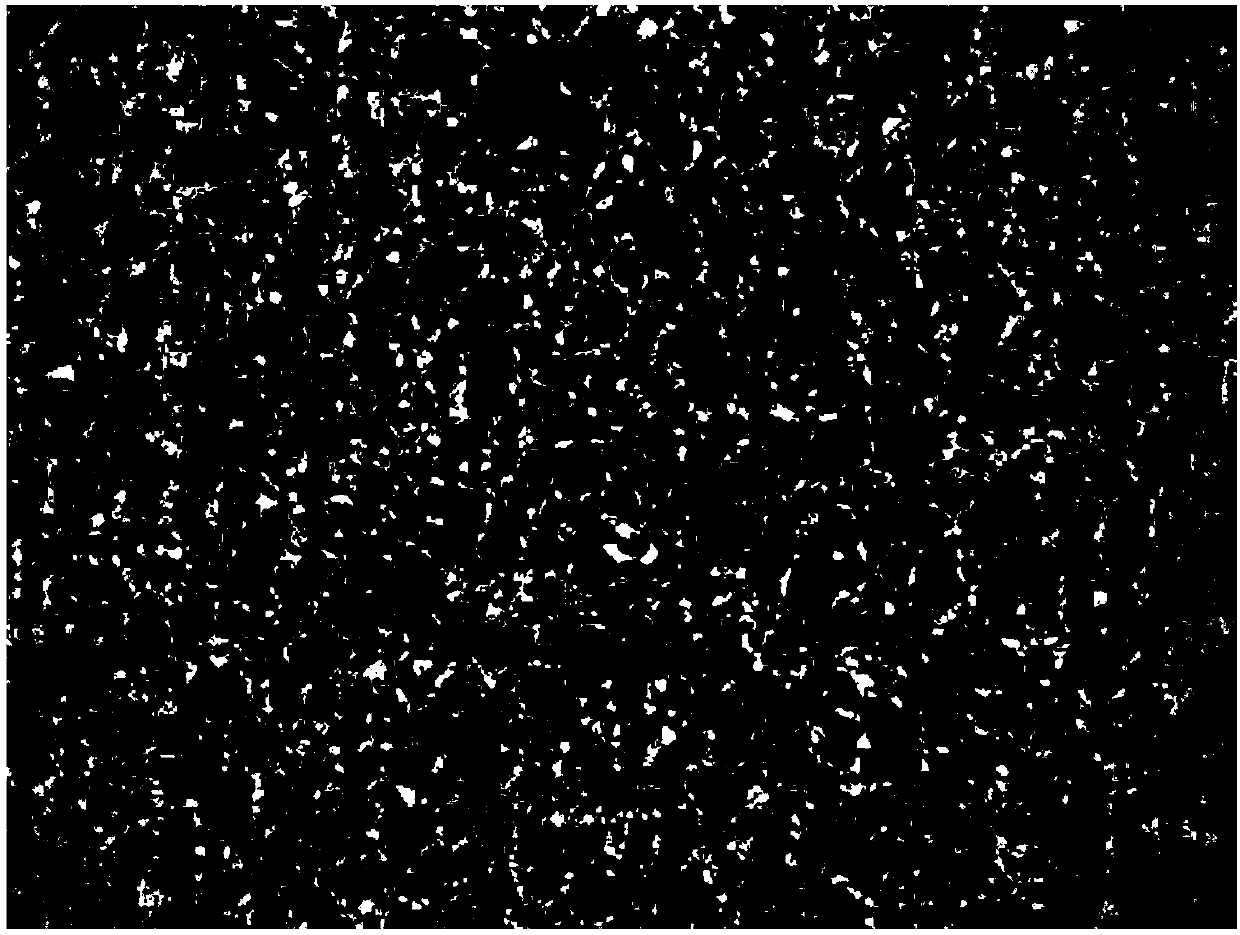

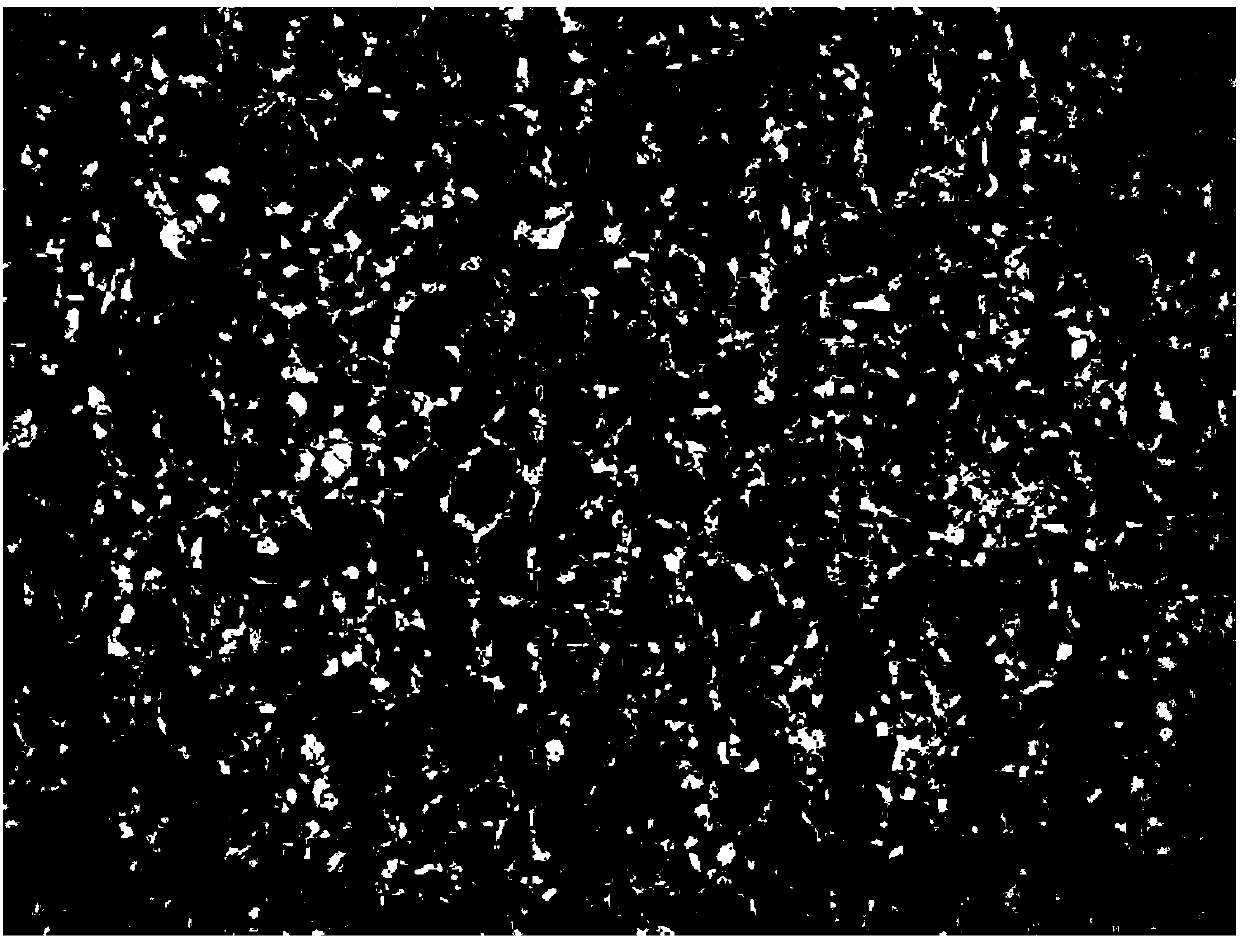

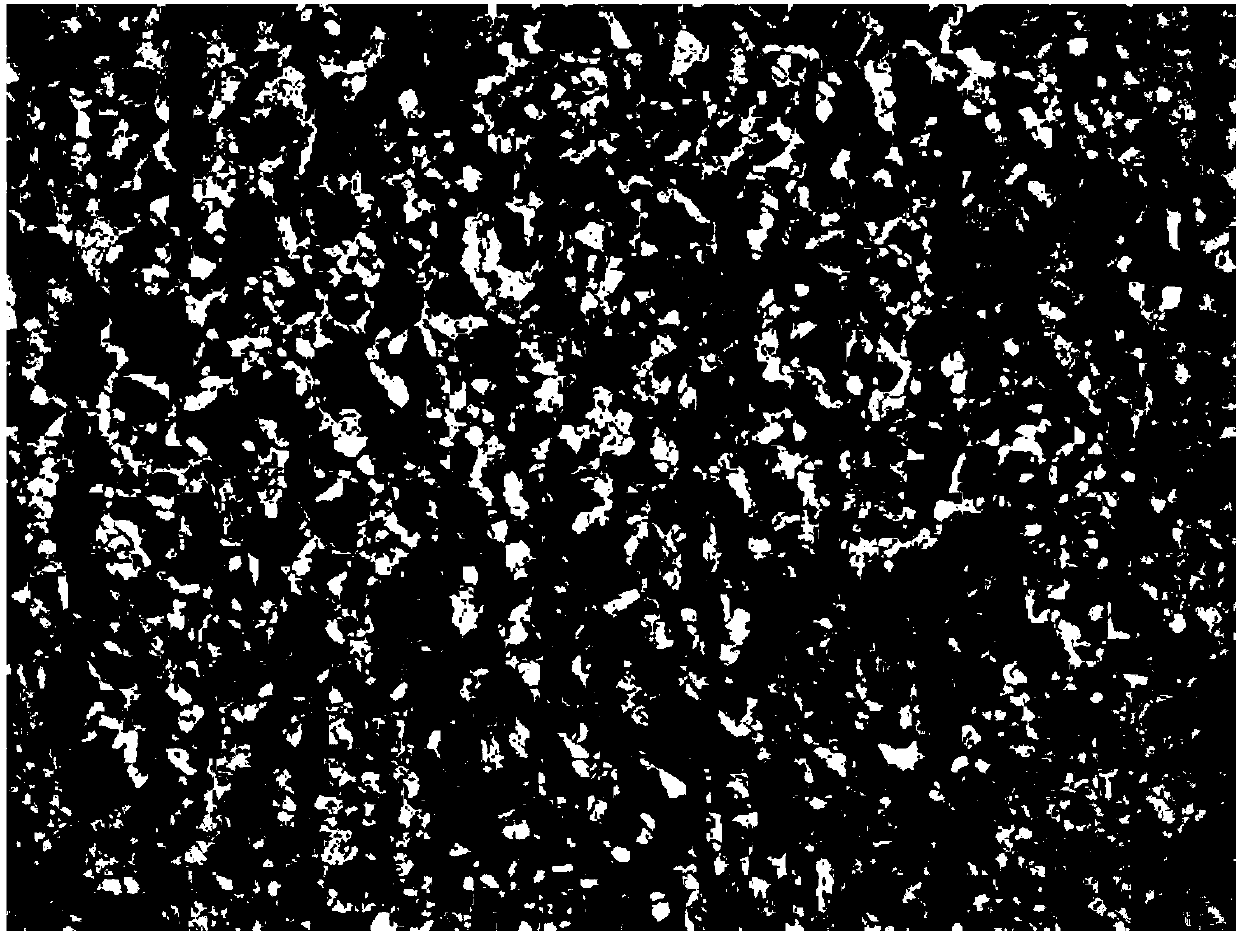

Image

Examples

Embodiment 1

[0069] The technological process of present embodiment round steel smelting method sees Figure 9 .

[0070] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 390mm×510mm. The chemical composition of the obtained continuous casting slab is in the following range in terms of mass percentage: C: 0.35~0.55% , Si: 0.10~0.50%, Mn: 0.80~1.20%, P: ≤0.030%, S: 0.01~0.04%, Cr: ≤0.30%, Ni: ≤0.30%, Cu: ≤0.05%, Mo: ≤0.20 %, Al: 0.01-0.05%, V: 0.05-0.20%, N: 0.005-0.2%, Pb: ≤0.02%, Sn: ≤0.03%, and the balance is Fe and unavoidable impurity elements.

[0071] During the continuous casting process, the pouring superheat degree shall not exceed 35°C, the continuous casting casting speed shall not exceed 0.15 to 0.65m / min, the total reduction under light reduction shall be 1 to 10mm, the specific water content shall not exceed 0.5L / Kg, and the electromagnetic stirring current of the...

Embodiment 2

[0076] The technological process of present embodiment round steel smelting method sees Figure 10 .

[0077] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 390mm×510mm. The chemical composition of the obtained continuous casting slab is in the following range in terms of mass percentage: C: 0.35~0.55% , Si: 0.10~0.50%, Mn: 0.80~1.20%, P: ≤0.030%, S: 0.01~0.04%, Cr: ≤0.30%, Ni: ≤0.30%, Cu: ≤0.05%, Mo: ≤0.20 %, Al: 0.01-0.05%, V: 0.05-0.20%, N: 0.005-0.2%, Pb: ≤0.02%, Sn: ≤0.03%, and the balance is Fe and unavoidable impurity elements.

[0078] During the continuous casting process, the pouring superheat degree shall not exceed 35°C, the continuous casting casting speed shall not exceed 0.15 to 0.65m / min, the total reduction under light reduction shall be 1 to 10mm, the specific water content shall not exceed 0.5L / Kg, and the electromagnetic stirring current of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com