Heating control system and method for blade of wind power generating set

A wind turbine, heating control technology, applied in wind turbines, wind power generation, engines, etc., can solve the problems of blade damage, high heating output power, and low air heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Features and exemplary embodiments of various aspects of embodiments of the present invention will be described in detail below. In the following detailed description, numerous specific details are set forth in order to provide a thorough understanding of embodiments of the invention.

[0048] The embodiment of the present invention provides a heating control system and method for the blades of a wind power generating set. By adopting the technical solution in the embodiment of the present invention, the heating control system of the blades of a wind generating set can have high reliability and safety, and at the same time It can also achieve a good deicing effect under the premise of improving the blade heating efficiency.

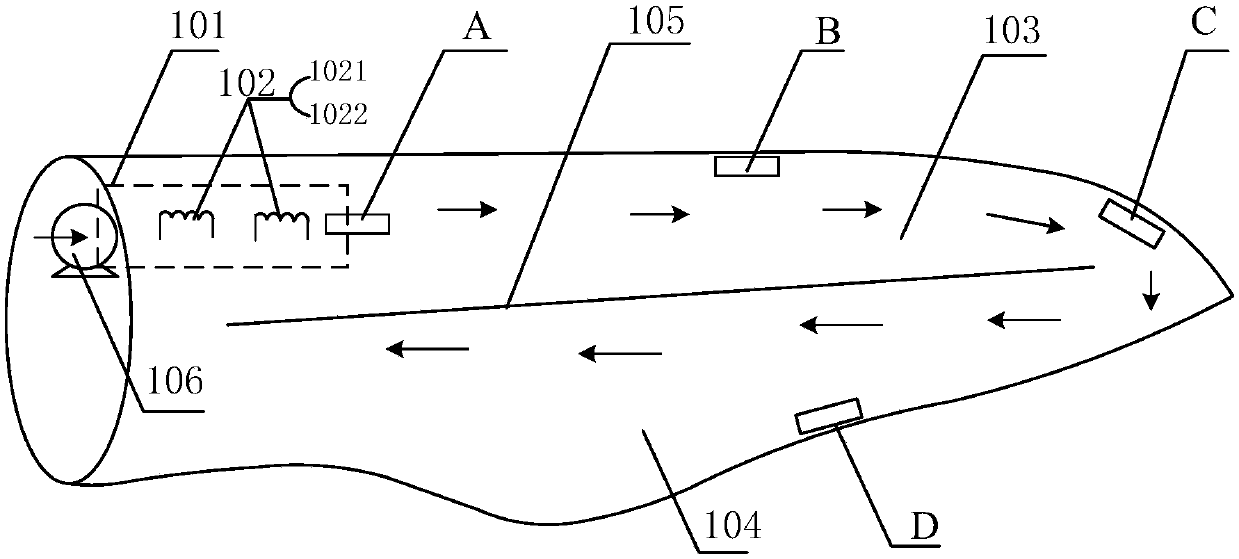

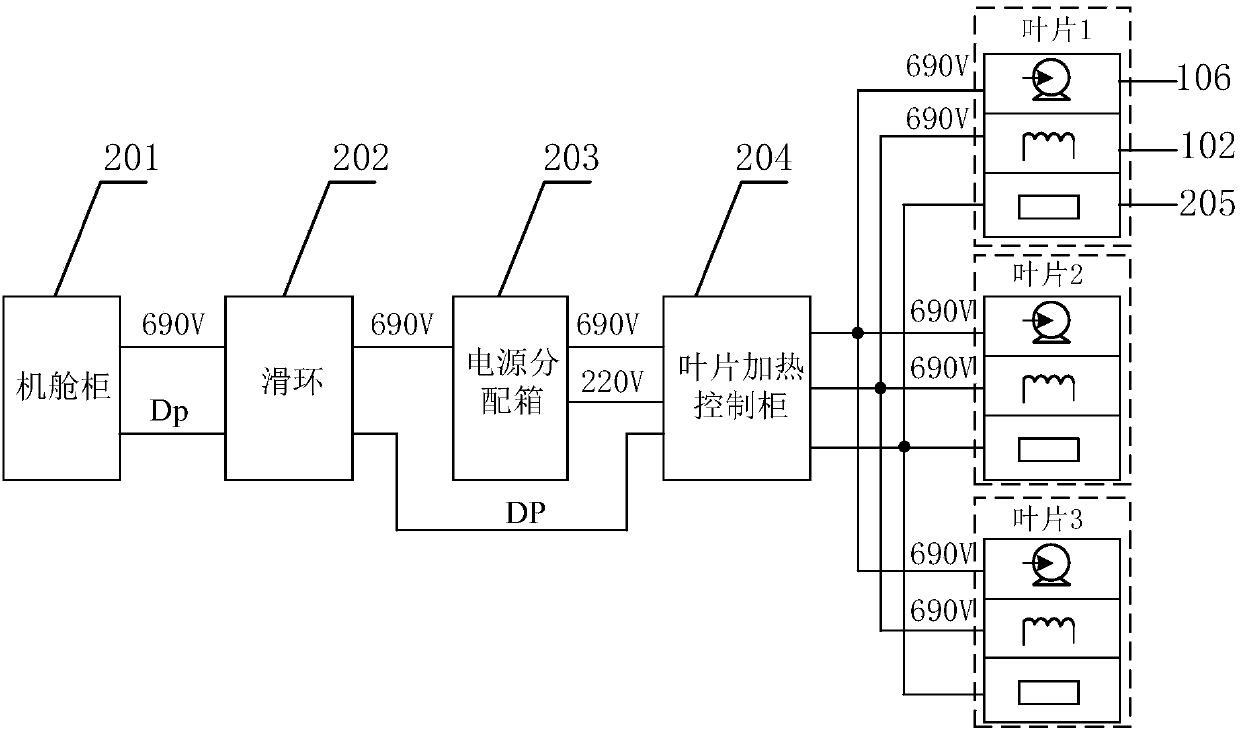

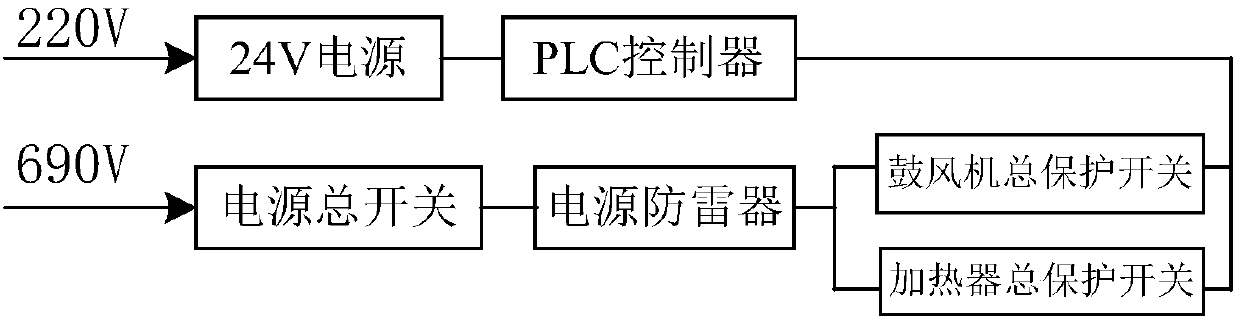

[0049] figure 1 It is a schematic structural diagram of a heating control system for blades of a wind power generating set provided by an embodiment of the present invention. like figure 1 As shown, the heating control system includes a heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com