Packaging cover and manufacturing method thereof

A technology for encapsulating a cover plate and a manufacturing method, which is applied in the directions of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve problems such as poor thermal conductivity and affect the encapsulation effect, and achieves a stable encapsulation structure and improves the heat dissipation effect. , the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

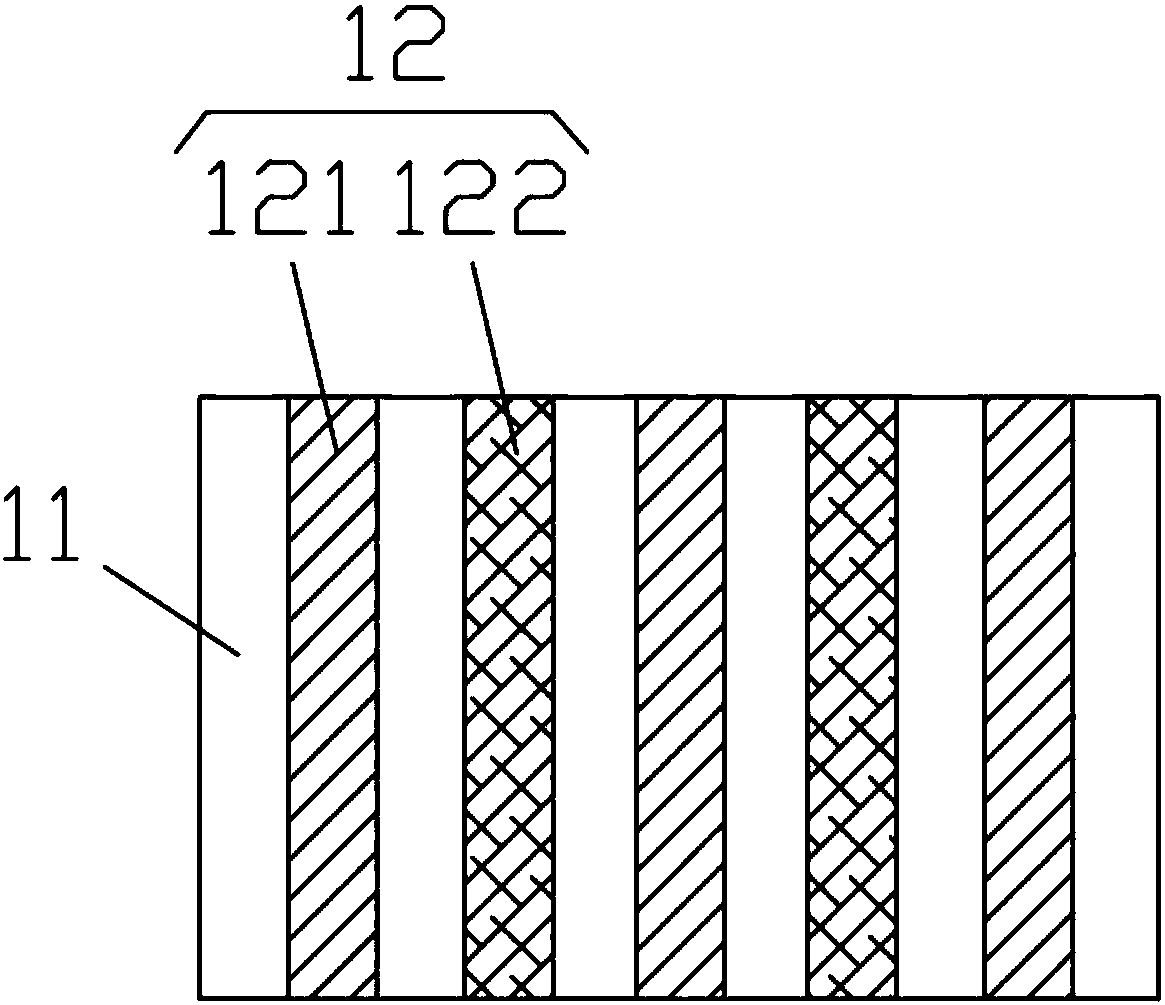

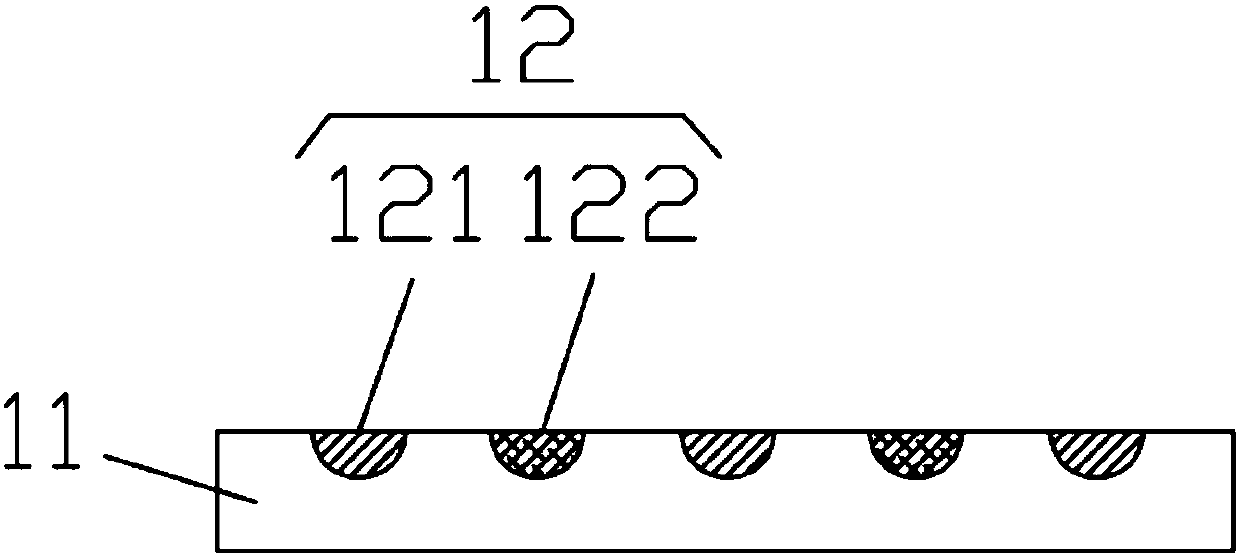

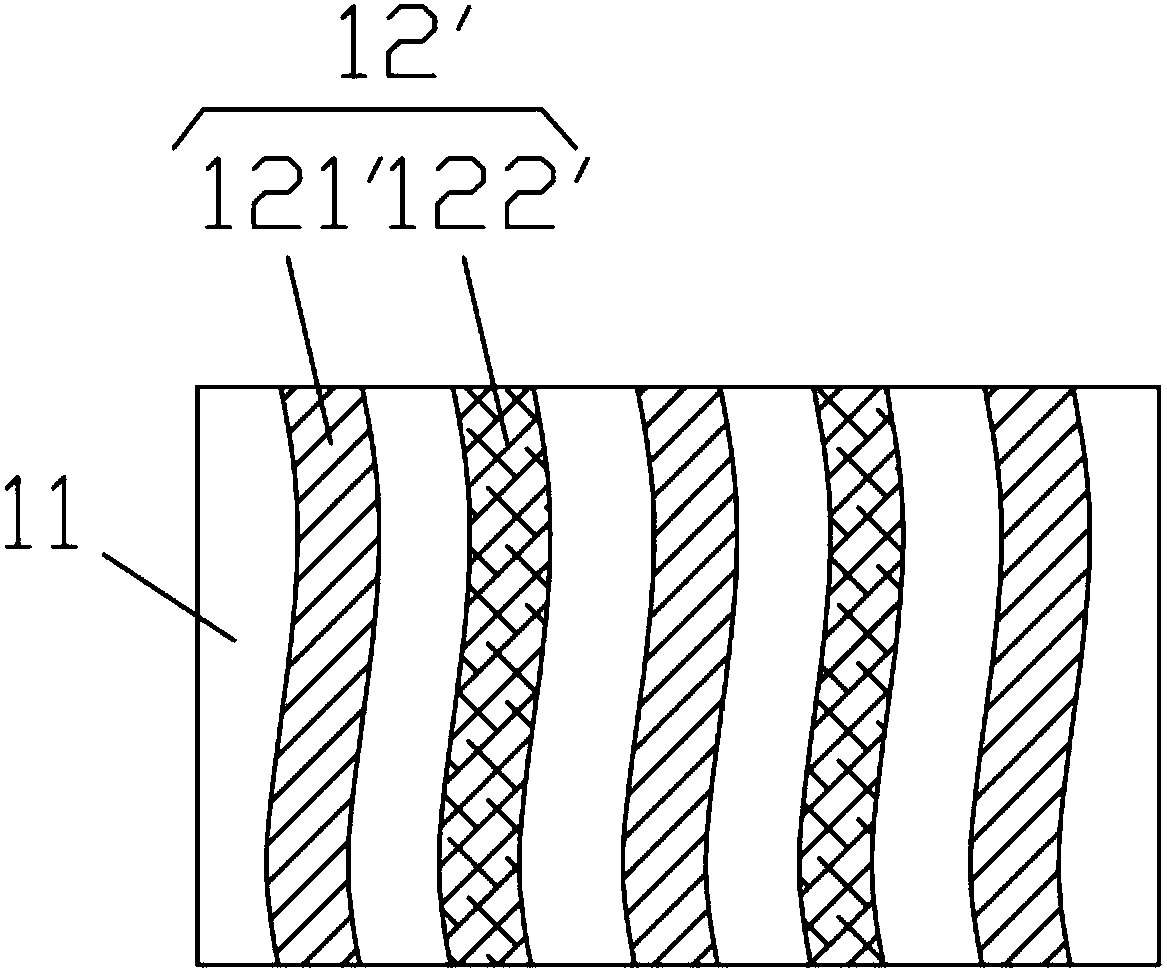

[0033] In order for those skilled in the art to better understand the technical solution of the present invention, the encapsulation cover provided by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

[0034] The packaging structure usually uses a packaging cover made of metal or non-metallic materials to effectively prevent the intrusion of water and oxygen. However, this package cover often has the following problems:

[0035] First, the metal package cover plate is less effective in resisting cold and heat shocks. Once the environment changes in temperature and temperature, the deformation of the metal will easily cause the metal cover plate to peel off from the encapsulant, affecting the encapsulation effect. And the metal cover is more susceptible to environmental damage.

[0036] Second, although the non-metallic package cover can avoid the phenomenon that the metal cover has poor thermal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com