Cooling-fin cylindrical battery pack heat dissipation device and method employing composite phase changing material

A technology of composite phase change materials and heat dissipation fins, which is applied to battery pack parts, secondary batteries, circuits, etc., can solve the problems of increasing the temperature difference of the battery pack, detrimental to the overall performance of the battery pack, and increasing the battery pack, etc., to achieve improved Temperature uniformity, improved heat dissipation and stability, and reduced design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

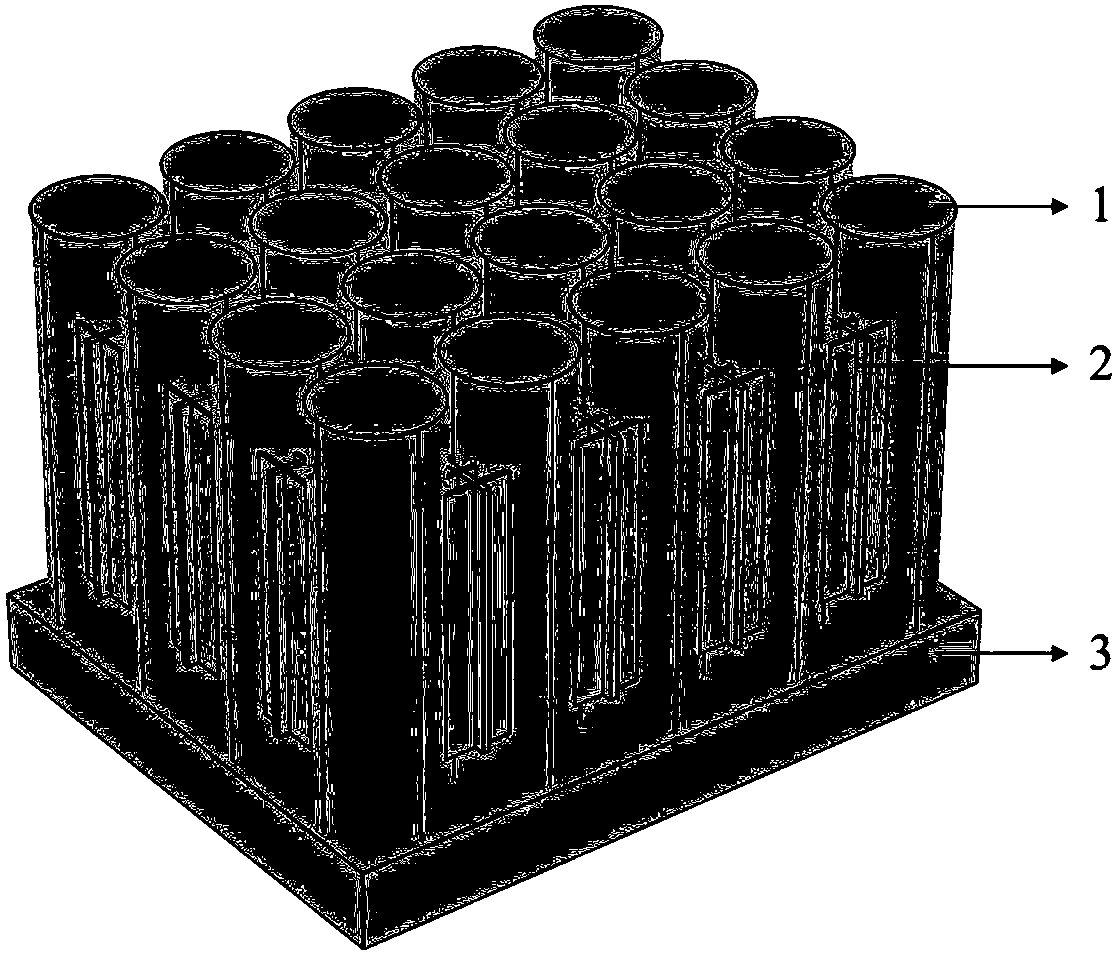

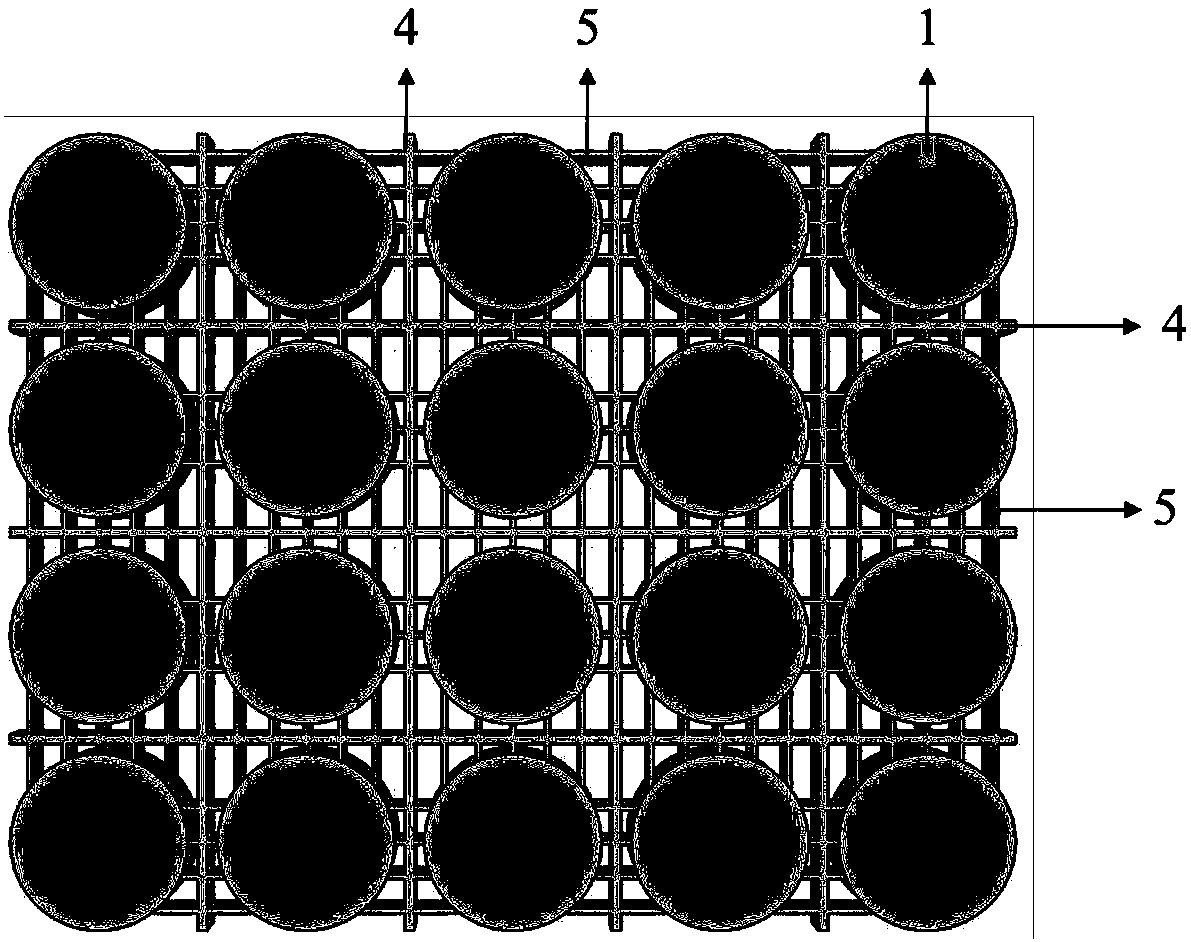

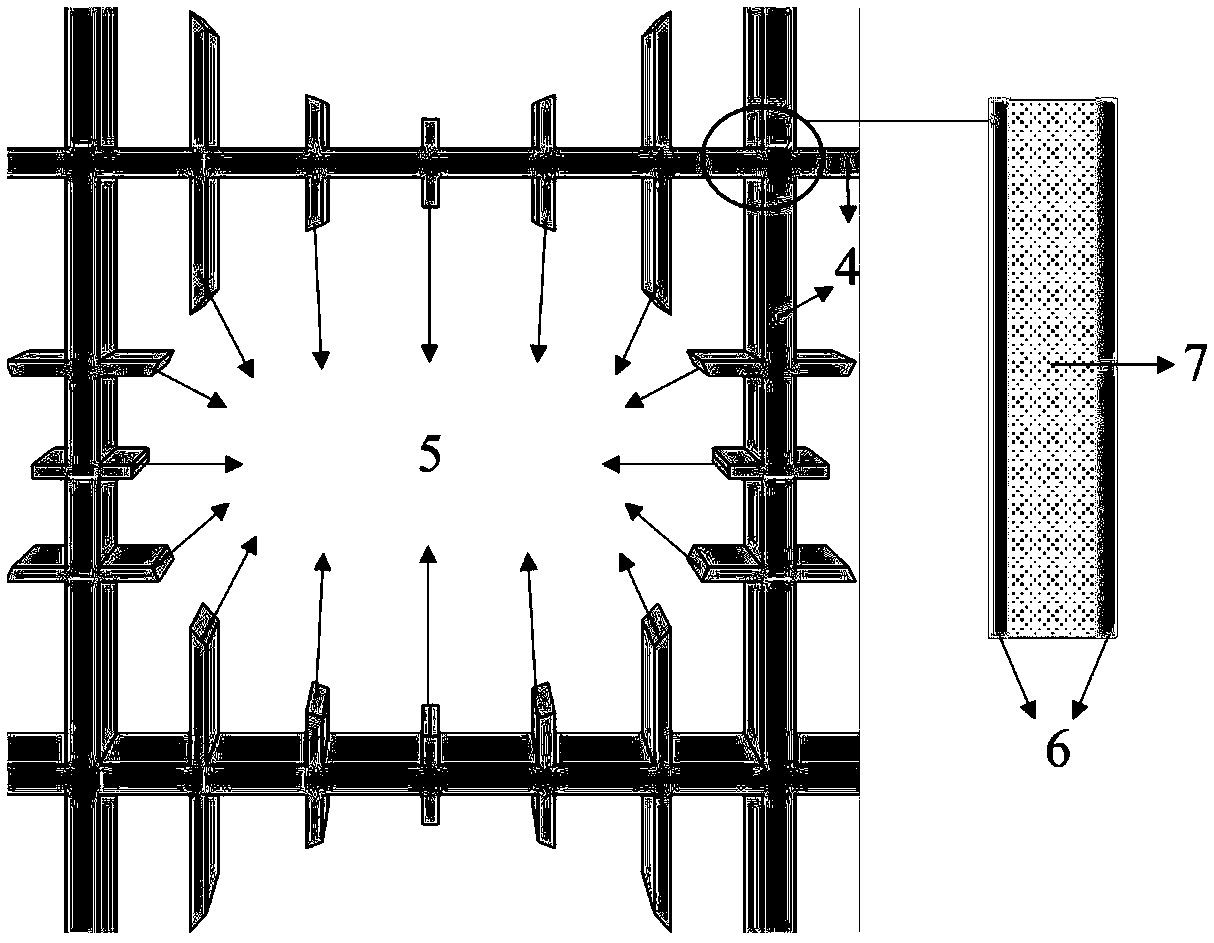

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0025] The radiating fins adopted in the present invention can be processed by currently quite mature cold-rolling and welding processes, wherein the main fins are shell structures, and the phase-change materials are encapsulated inside, and the phase-change materials are solid at normal temperature, so the encapsulation process is relatively Simple, can be packaged by welding, and various types of fins can be selected for the auxiliary fins, such as pin fins, straight ribs, ring ribs, and sleeve fins.

[0026] The radiating fins using the composite phase change material of the present invention need to cooperate with the cylindrical battery. The height, spacing, and thickness of the ribs can be adjusted according to the actual situation of the battery pack, but the sub-fins need to be in tangential contact with the surface of the battery case. For the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com