Automatic charging veneer reeling machine

An automatic feeding and rolling machine technology, applied to metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of inconvenient calibration, inconvenient loading and time-wasting of large-scale plate rolling machines, and reduce labor costs. Labor intensity, convenient correction, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

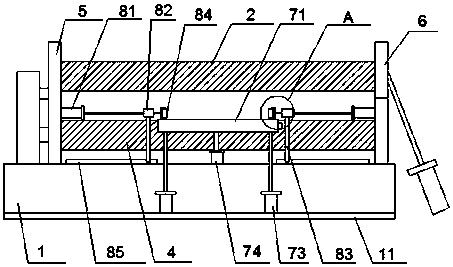

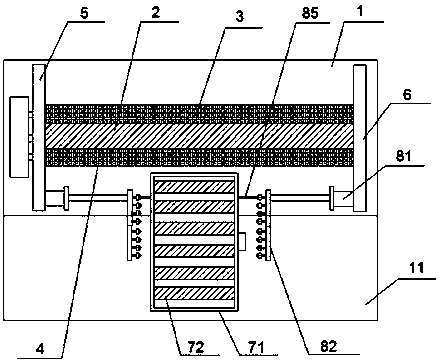

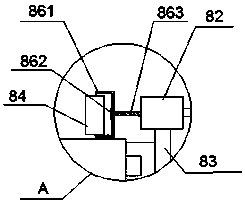

[0017] As shown in the figure, an automatic feeding plate rolling machine according to the present invention includes a base 1, an electrical control system, an upper roller 2, a lower roller 3, a side roller 4, a left bracket 5 and a right bracket 6, the left The support 5 and the right support 6 are arranged on the base 1 parallel to each other, and the two ends of the upper roller 2, the lower roller 3 and the side roller 4 are respectively corresponding to the left support 5 and the right support 6 through bearing seats. Connected and driven by an electrical control system, a feeding device 7 is provided on the base 1 close to the side roller 3, and the feeding device 7 includes a support frame 71, a transmission roller 72, a lifting cylinder 73 and an adjusting cylinder 74, the bottom of one side of the base 1 close to the side roller 3 extends horizontally outwards with a fixed plate 11, the adjusting cylinder 74 is set on the base 1, and the lifting cylinder 73 is set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com