Double-returned material auxiliary peeling machine

A peeling machine and material return technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as mounting or adhesion, operator personal injury, and increased labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

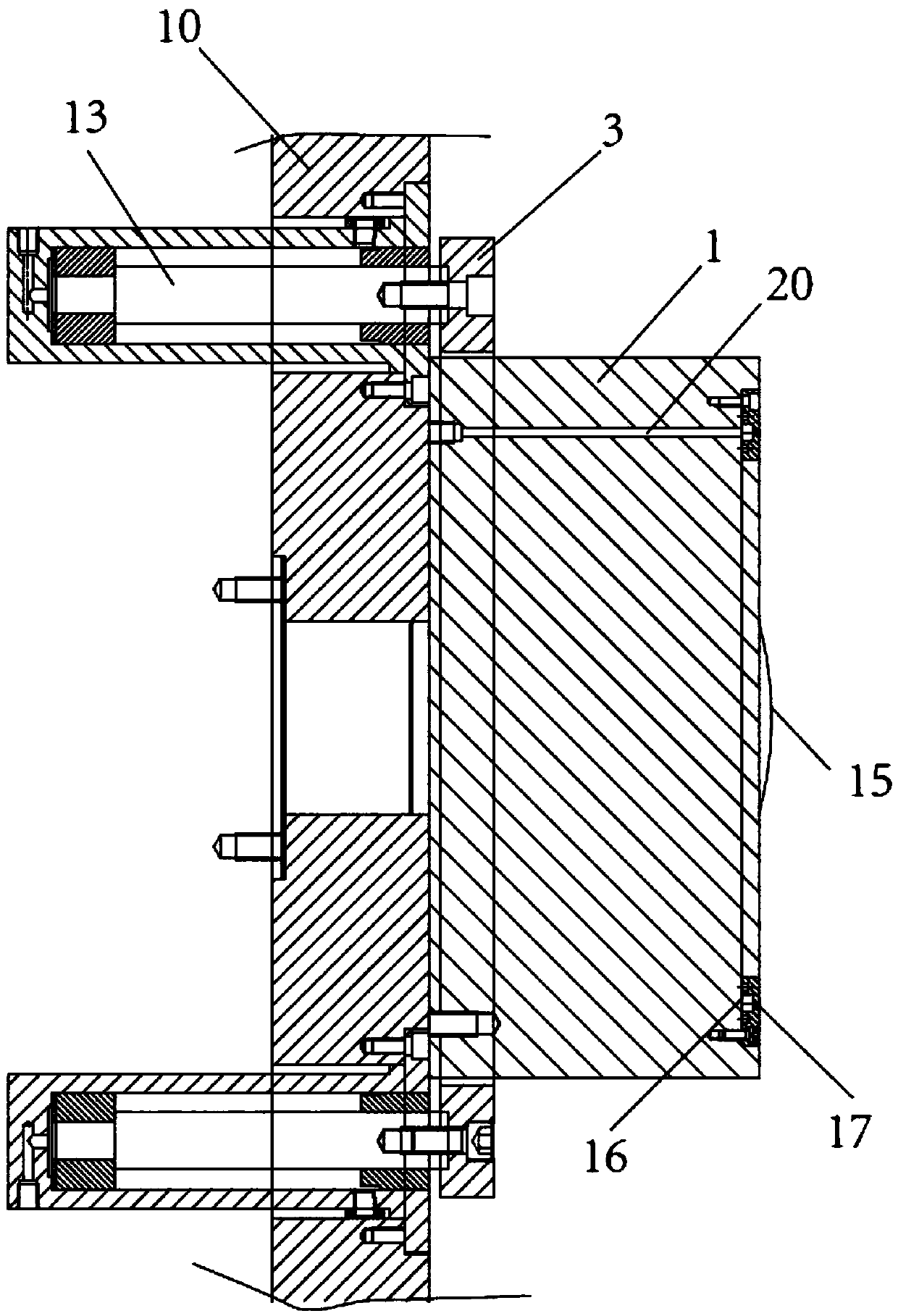

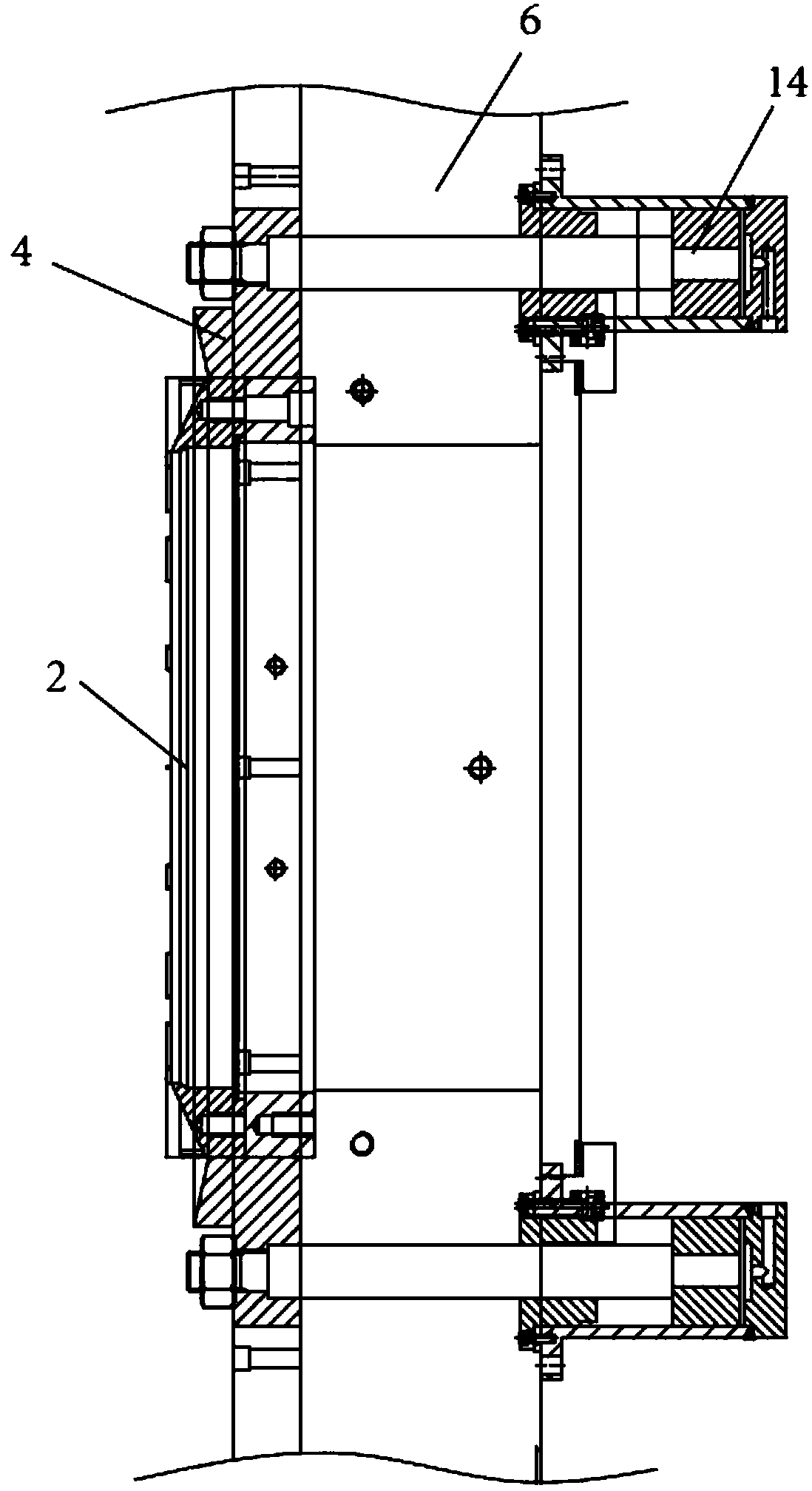

[0020] refer to figure 1 and figure 2 As shown, an embodiment of the double-returning auxiliary peeling machine of the present invention includes a push head 1 and a peeling cutter 2 that are arranged oppositely, and the push head 1 and the peeling cutter 2 cooperate with peeling, and the outer surface of the push head 1 is sleeved with a second A pusher ring 3, the outer surface of the peeling tool 2 is sleeved with a second pusher ring 4, the above-mentioned first pusher ring 3 and the second pusher ring 4 can respectively stick to the surface of the push head 1 and the peeling tool 2. The connected or mounted leather is pushed and removed, so that there is no leather on the surface of the push head 1 and the peeling tool 2, and the function of automatic unloading is effectively realized without manual operation.

[0021] The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com