Microbe inoculator with boron nitride film coating and preparation method thereof

A boron nitride film and inoculator technology, which is applied in the method of biological material sampling, coating, metal material coating process, etc., to achieve the effects of low coating stress, small secondary pollution and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

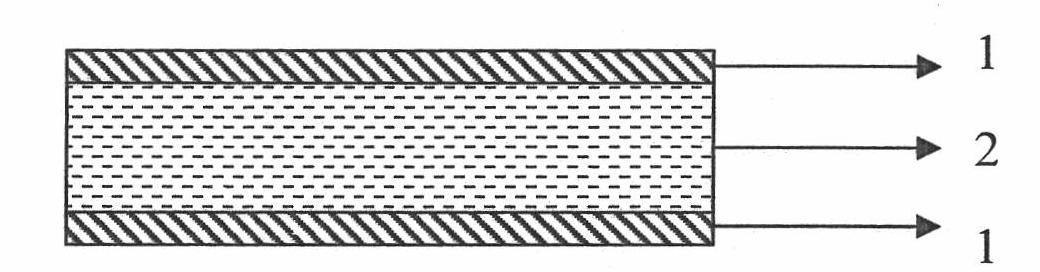

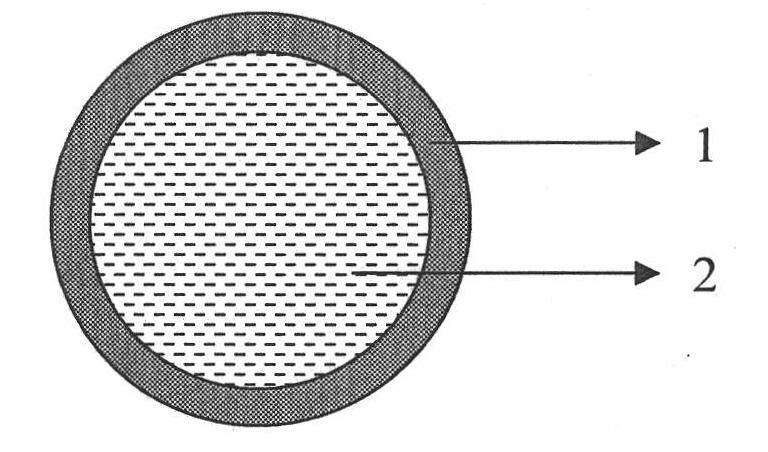

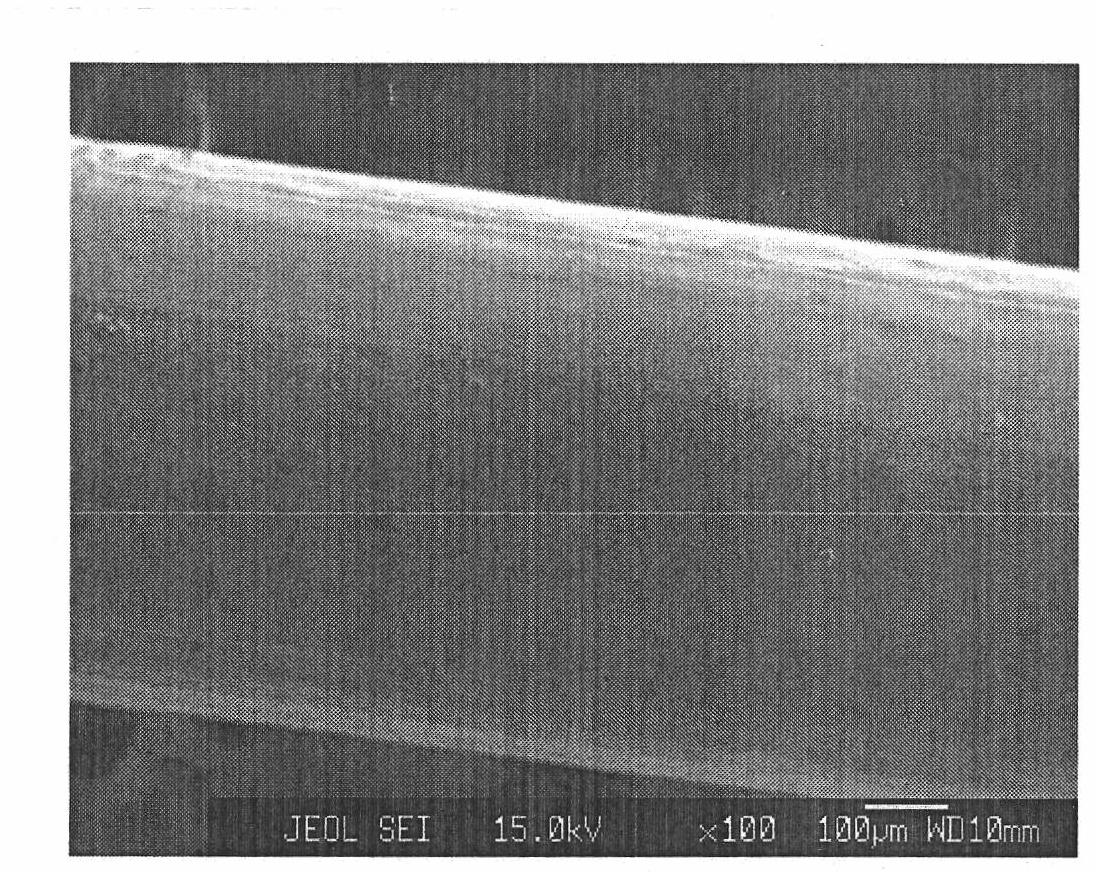

[0021] Using radio frequency magnetron sputtering method to grow BN film coating on nickel-chromium alloy inoculation wire, there are two processes of pretreatment and BN film coating growth.

[0022] 1) Pretreatment of nickel-chromium alloy seeding wire: use sandpaper to remove the oxide layer on the surface of nickel-chromium alloy seeding wire, immerse it in acetone and ethanol solution and ultrasonically clean it for 5-25 minutes, then ultrasonically clean it with deionized water for 5-25 minutes, Repeat the above cleaning 2 to 3 times until the surface is very clean, take out the nickel-chromium alloy inoculation wire and dry it.

[0023] 2) BN film coating growth: the nickel-chromium alloy inoculation wire is placed flat on the sample stage of the sputtering deposition equipment, and high-purity hexagonal boron nitride (hBN) is used as the target material, (the purity of the target material is preferably 99.8%, The diameter can be 50 mm), and the deposition chamber is ev...

Embodiment 2

[0027] The alloy seeding wire in Example 1 was replaced with platinum seeding wire, and a BN film coating was grown on the platinum seeding wire by radio frequency magnetron sputtering.

[0028] Method is with embodiment 1.

Embodiment 3

[0030] A magnetically enhanced arc plasma (CVD) method is used to grow a BN film coating on a nickel-chromium alloy inoculated wire. There are two processes of pretreatment and BN film coating growth.

[0031] The pretreatment of nickel-chromium alloy seeding wire: with embodiment 1.

[0032] BN film coating growth process: place the nickel-chromium alloy seed wire on the sample stage of the radio frequency magnetron sputtering deposition equipment, N 2 , Ar, H 2 and BCl 3 The mixed gas is the reaction gas, and the gas flow ratio is N 2 :Ar:H 2 :BCl 3 =98:400:100:2, the working pressure is 2-50Pa, the bias voltage is 120V to assist the deposition, the arc discharge current is 10-15A, the deposition time is 30-120 minutes, and the BN film coating is grown on the surface of the nickel-chromium alloy seed wire, The thickness is about 0.5 microns.

[0033] To obtain a BN film coating with a thickness of 0.05-5 microns, the growth time of the BN film can be controlled at 15-9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com