A casting damping device for stern bearing and its preparation method

A technology for damping devices and bearings, which is applied to transmissions, shafts, bearings, and bearing components of synchronous propulsion components. It can solve the problems of difficult maintenance and disassembly, inability to use stern bearings, and high requirements for pouring environments, so as to achieve good vibration isolation The effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

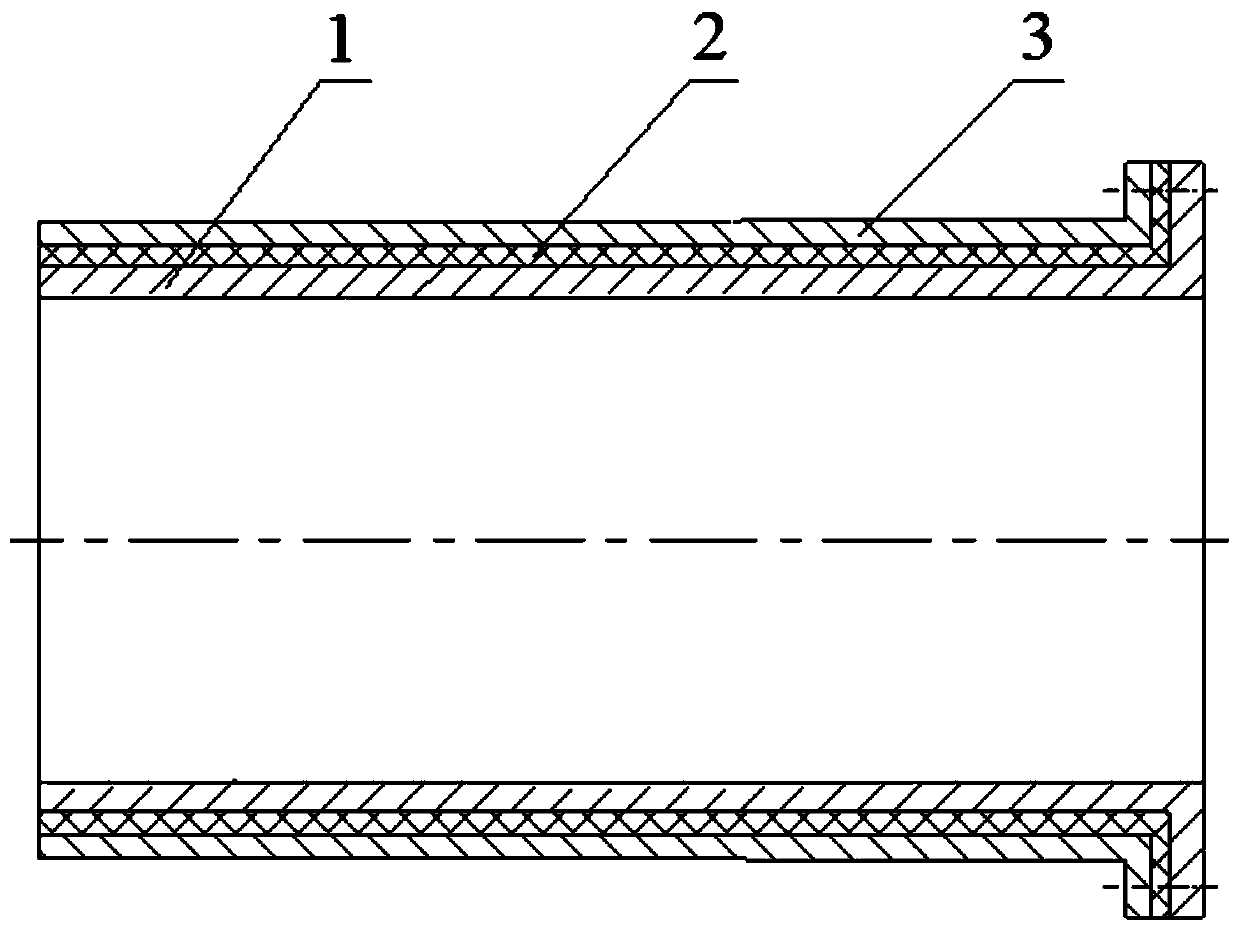

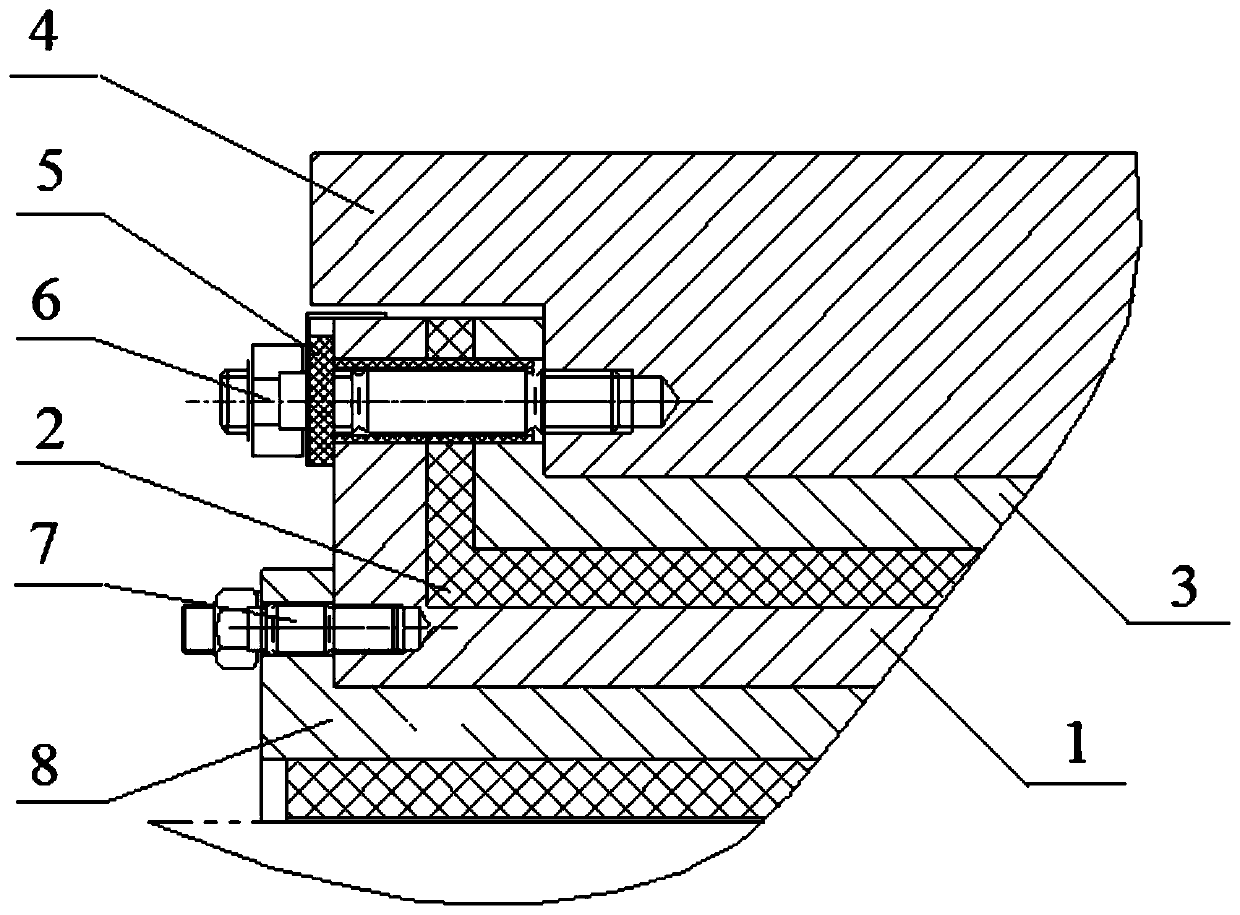

[0042] like figure 1 As shown, a casting damping device for a stern bearing, the damping device includes an inner bushing 1 , a casting body 2 and an outer bushing 3 .

[0043] Among them, the inner bush 1 and the outer bush 3 are both cylindrical with a flange at one end, the outer bush 3 is set on the inner bush 1, and the casting body 2 is solidified by pouring the inner bush 1 and the outer bush Between sets of 3.

[0044] After the casting body 2 is solidified, in the damping device, a circle of through holes and a circle of threaded holes are evenly distributed along the circumference on the flanges of the inner bushing 1 , the casting body 2 and the outer bushing 3 .

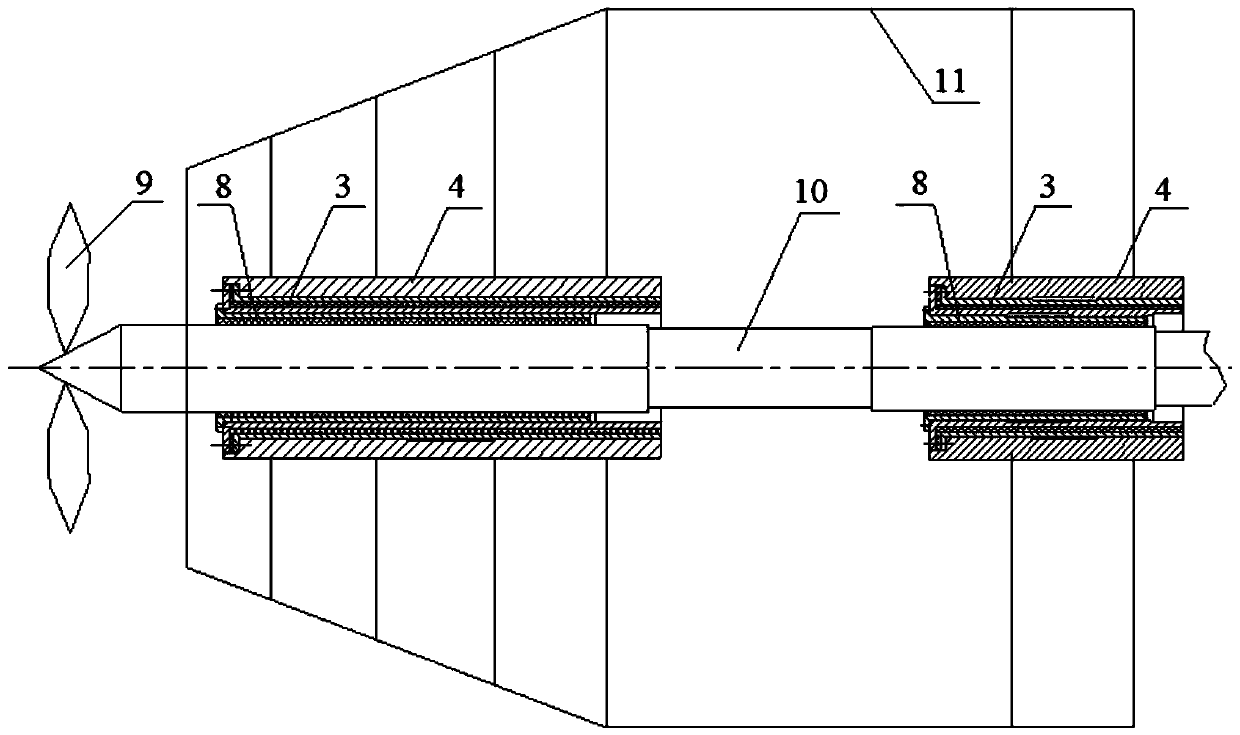

[0045] image 3 It is a schematic diagram of the overall arrangement of the damping device in the hull 11, showing the specific positions of the propeller 9, the stern bearing 8, the damping device, the stern bearing hub 4, and the stern shaft 10 in the hull 11, As can be seen from the figure, the dampin...

Embodiment 2

[0066] like figure 1 As shown, a casting damping device for stern bearing, the thickness of the inner bush 1 is 36mm, the thickness of the outer bush 3 is 32mm, the thickness of the casting body 2 is 18mm, and the casting body material is German EPOCAST 36 casting type epoxy gasket, its The performance indicators are:

[0067] Tensile strength ≥ 49.4MPa, compressive strength ≥ 164MPa, cantilever beam unnotched impact strength ≥ 2.0kJ / m 2 , heat distortion temperature ≥ 90 ℃, Barcol hardness ≥ 55;

[0068] Elastic modulus (E) = 5.61GPa; density (ρ) = 1670kg / m 3 ; Poisson's ratio (μ) = 0.337;

[0069] The remaining parts are the same as those in the casting damping device for the stern bearing described in Embodiment 1.

[0070] The steps of the preparation method of the casting damping device for the stern bearing described in this embodiment are as follows:

[0071] (1) Assembly positioning: same as step (1) of embodiment 1.

[0072] (2) The first sealing treatment: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com