Bucket with supporting bases

A technology for supporting bases and buckets, applied to mechanically driven excavators/dredgers, layered products, metal layered products, etc., can solve the problems of bucket corrosion damage, heavy weight, etc., to prevent corrosion damage, Effect of improving cushioning characteristics, excellent wear resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

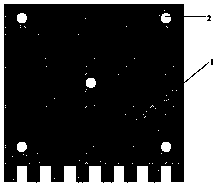

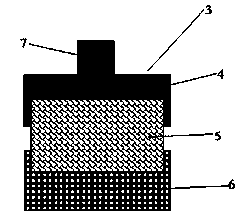

[0021] see Figure 1-2, a bucket with a support base proposed by the present invention, the bucket includes a bucket body 1, five support base mounting holes 2 are provided at the bottom of the bucket body 1, four of which support The base installation holes 2 are located at the four corners of the bottom of the bucket body 1, the fifth support base installation hole 2 is located in the central area of the grab body 1, and the five support bases 3 are detachably installed On the five support base installation holes 2, the support base 3 includes a metal base 4, a first buffer resin layer 5 and a second wear-resistant resin layer 6, and the upper end of the metal base 4 has a The metal post 7 matched with the installation hole 2 has a first groove for accommodating the first buffer resin layer 5 at the lower end of the metal base 4, and a first groove for accommodating the first buffer resin layer 5 at the upper end of the second wear-resistant resin layer 6. In the second g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com