Device for testing fracture frost heaving force of rock under vertical load effect

A technology of rock cracks and vertical loads, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., and can solve the problem of poor installation accuracy of thin-film pressure sensors, the inability to consider the crack ice extrusion effect, and the error is difficult to control and other problems, to achieve the effect of simple structure, controllable measurement error and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and implementation example the present invention is further described:

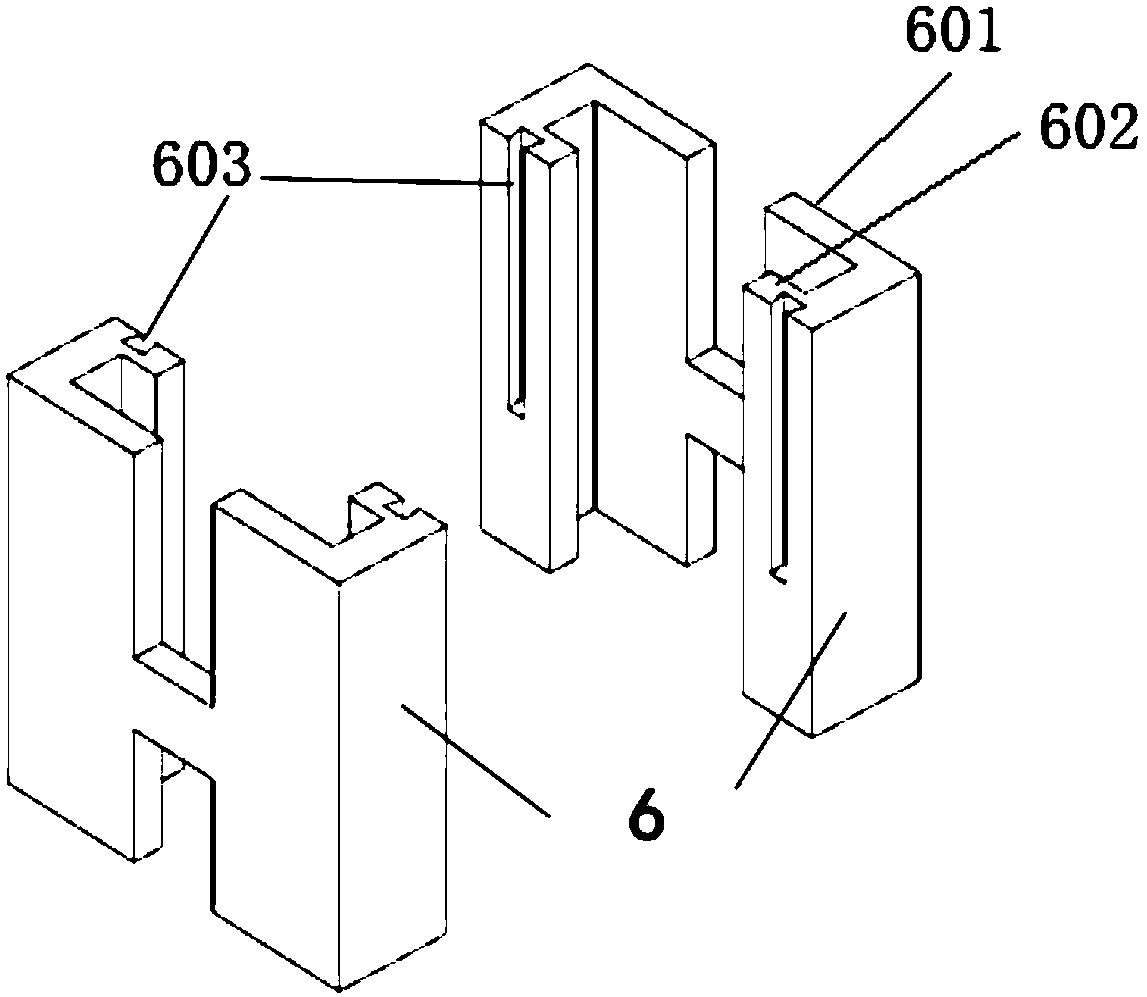

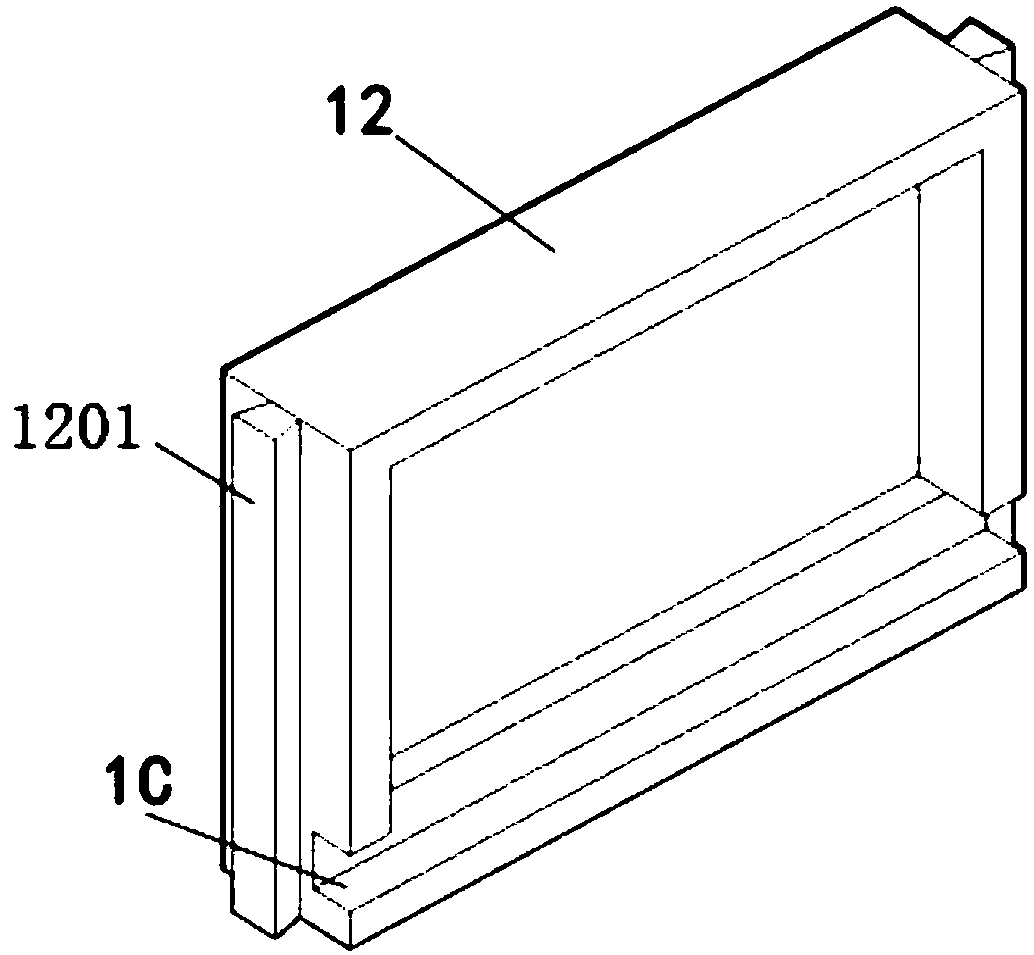

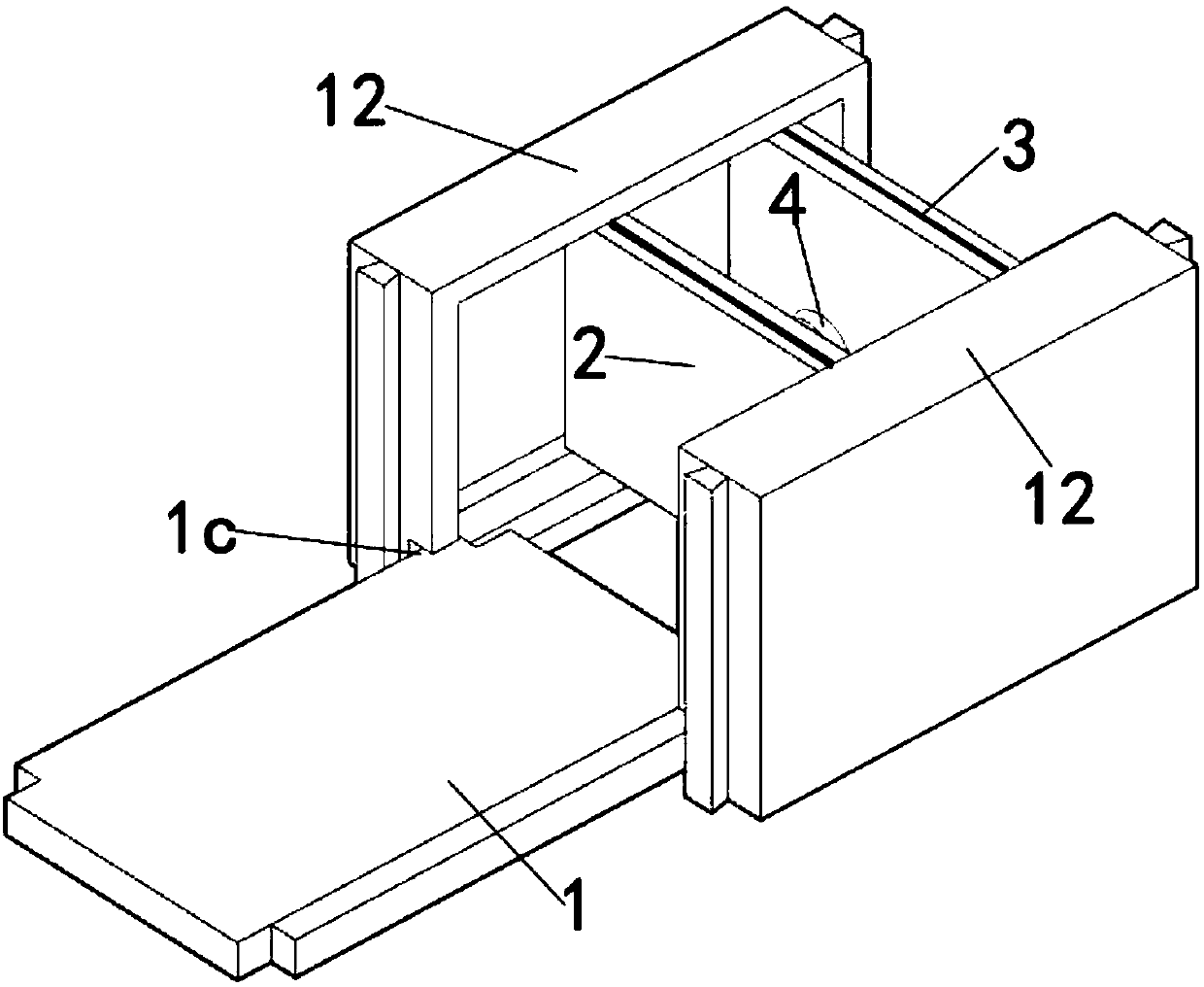

[0037] A rock crack frost-heaving test device under the action of a vertical load, comprising a heat-insulating bearing base 1, characterized in that the two sides of the heat-insulating bearing base 1 are respectively connected to the bottoms of two drawer-shaped side wall steel frames 12 Connection, two vertical pressure steel plates 2 are arranged above the heat insulation bearing base 1 and between the two drawer-shaped side wall steel frames 12, and a hydraulic jack 4 is arranged between the two vertical pressure steel plates 2, and two H-shaped empty channel steel support 6, H-shaped empty channel steel support 6 comprises H-shaped support main body 601 and the inner crimp 602 that is arranged on two vertical sides of H-shaped support main body 601, inner crimp 602 and H-shaped support main body 601 A steel plate 8 is clamped between them, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com