Cylinder Bore For A Cylinder Housing Of An Internal Combustion Engine, And Arrangement Consisting Of Such A Cylinder Bore And A Piston

A technology for internal combustion engines and cylinder bores, applied in the direction of pistons, cylinders, cylinder heads, etc., can solve problems such as noise generation, and achieve the effects of effectively reducing friction, reducing friction components, and improving friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

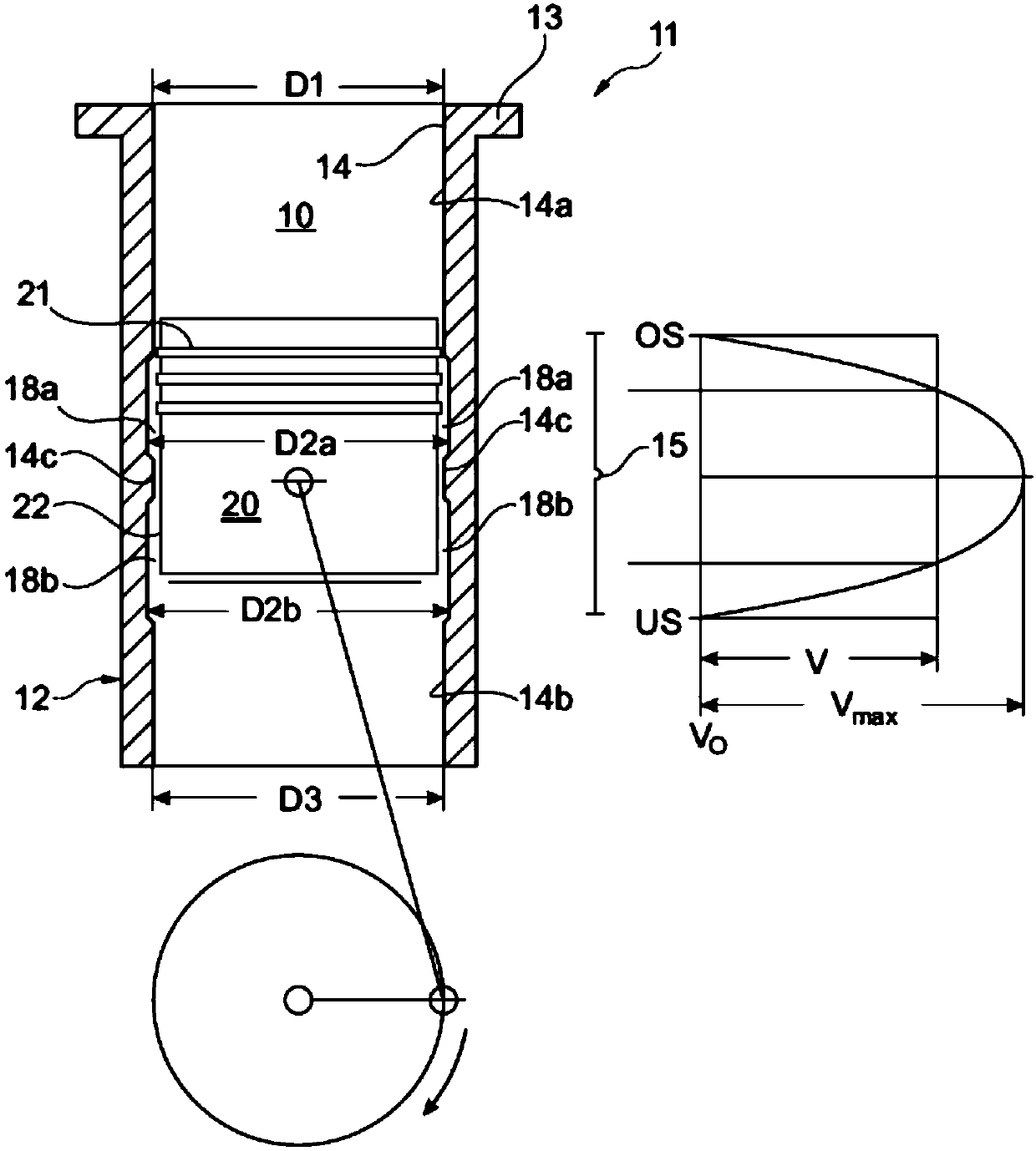

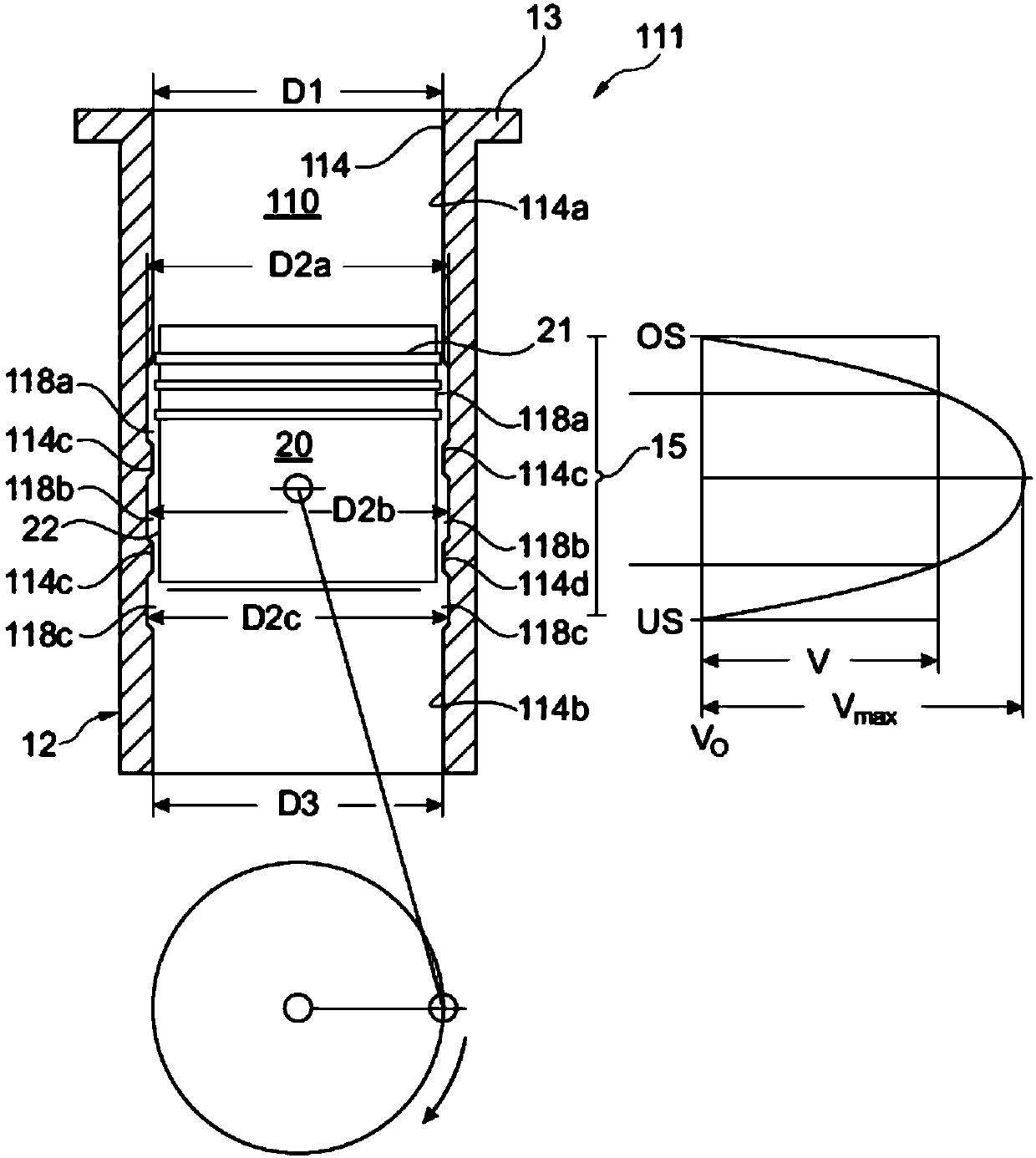

[0024] in figure 1 The cylinder bore 10 according to the present invention illustrated in the figure is constructed in the form of a cylinder liner 11. In an exemplary embodiment of a cast iron material with flake graphite, the cylinder liner 11 can be composed of a cast iron material, for example, and can be manufactured by centrifugal casting processing, for example. In the exemplary embodiment, the cylinder liner 11 has a shaft 12 with a circumferential flange 13 and a cylinder running surface 14.

[0025] The piston 20 with the piston ring 21 and the piston skirt 22 is guided up and down in the cylinder liner 11 during engine operation. During engine operation, the piston skirt 22 moves along the cylinder running surface 14 between the upper turning point OS and the lower turning point US, at which the piston 20 reaches a speed close to zero at the upper turning point OS and the lower turning point US v 0 . At the highest load point of the piston skirt 22, the minimum speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com