Belt pulley decoupler with sliding guide housing

A technology of belt pulley and decoupler, which is applied to components with teeth, belts/chains/gears, hoisting devices, etc., to achieve the effect of simplified assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

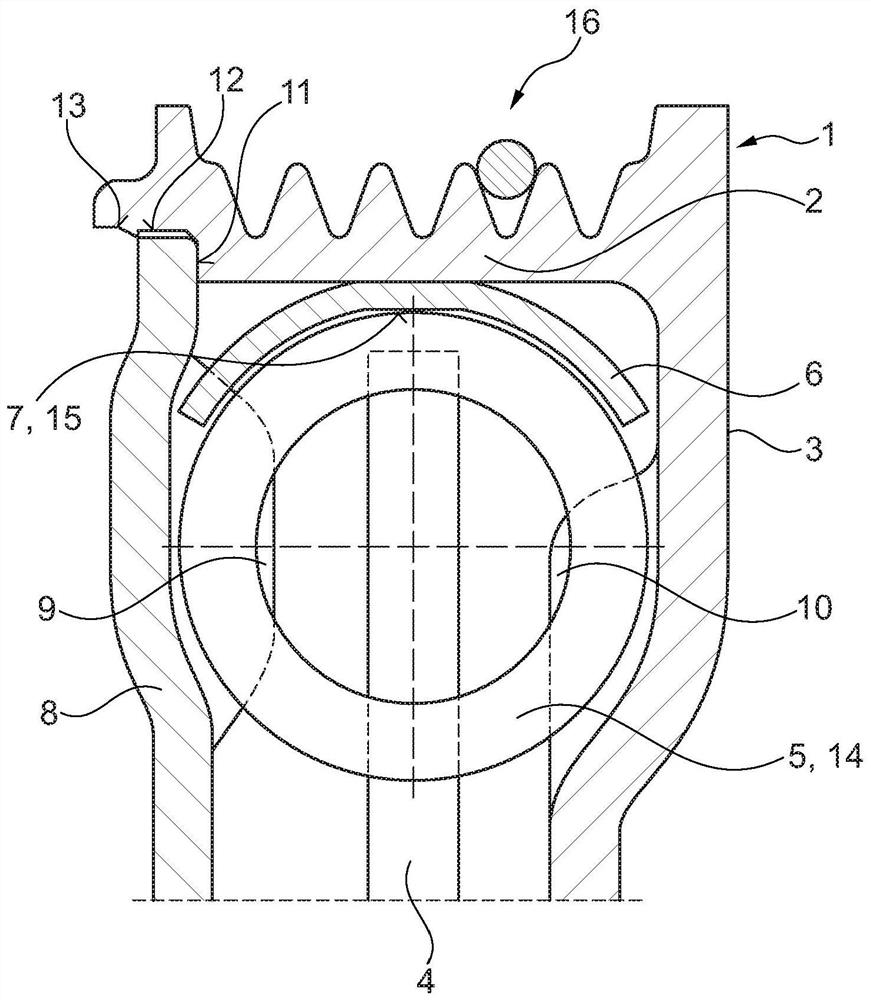

[0041] figure 1 A belt pulley decoupler 1 constructed from several elements is shown. The belt receiving area 2 is characterized in that it is the radially outer area of the belt pulley 3 . The pulley 3 is adapted to receive the ring. A drive flange 4 is arranged radially inside the belt receiving area 2 . An elastic element 5 , ie a spring, is arranged between the driving flange 4 and the belt pulley 3 . The elastic element 5 connects the drive flange 4 to the pulley 3 in a torque-transmitting and vibration-damping manner.

[0042] Another core component of the assembly is the sliding guide housing 6 . The slide housing 6 has a defined contact surface 7 which contacts the spring element 5 . The components of the cover 8 are likewise central. Cover 8 is a component that spatially isolates belt pulley decoupler 1 from the environment. A lubricating material, such as grease, can be provided in the pulley isolator by means of the cover without the lubricating material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com