Multifunctional lathe cutting fluid filtration device

A filter device and cutting fluid technology, applied in the direction of filtration separation, fixed filter element filter, maintenance and safety accessories, etc., can solve the problems affecting the surface processing effect of the workpiece, shorten the service life of the cutting fluid, and affect the processing effect of the workpiece, etc., to achieve Simple structure, reliable operation, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

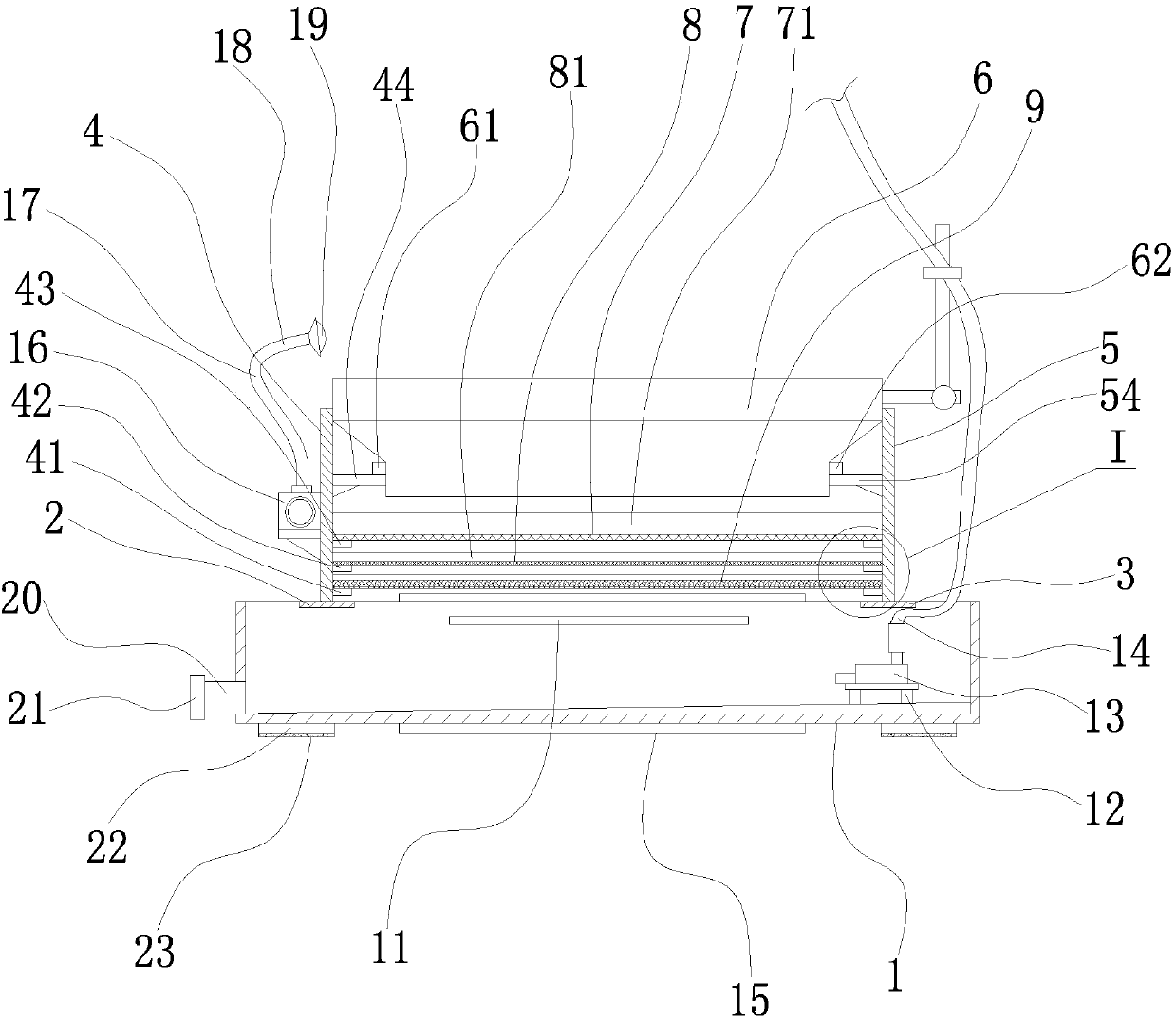

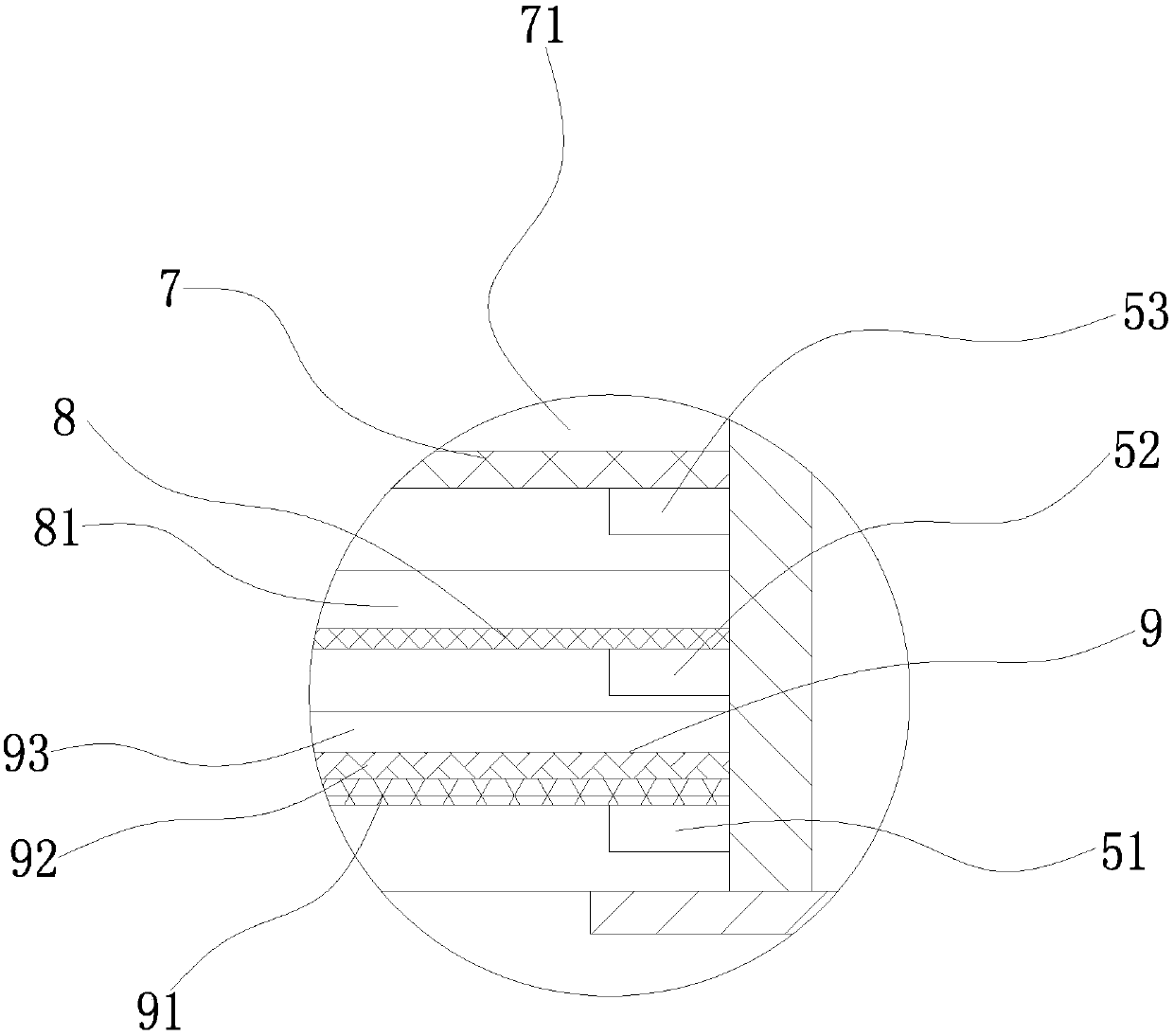

[0020] Example: such as figure 1 and figure 2 As shown, a multifunctional lathe cutting fluid filtering device includes a cutting fluid collection tank 1, the upper end of the cutting fluid collection tank 1 is fixedly provided with a left support plate 2 and a right support plate 3, and the left support plate 2 is fixed A first vertical support 4 is provided, and the right end surface of the first vertical support 4 is sequentially provided with a first positioning protrusion 41, a second positioning protrusion 42, a third positioning protrusion 43 and a first limit position from bottom to top. frame 44; the right support plate 3 is fixedly provided with a second vertical support 5, and the left end surface of the second vertical support 5 is sequentially provided with a fourth positioning projection 51, a fifth positioning projection 52, The sixth positioning projection 53 and the second limiting frame 54, a guide cover 6 is arranged between the first limiting frame 44 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com