Combined type industrial sludge drying device

A technology for industrial sludge and drying equipment, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Low efficiency and other problems, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

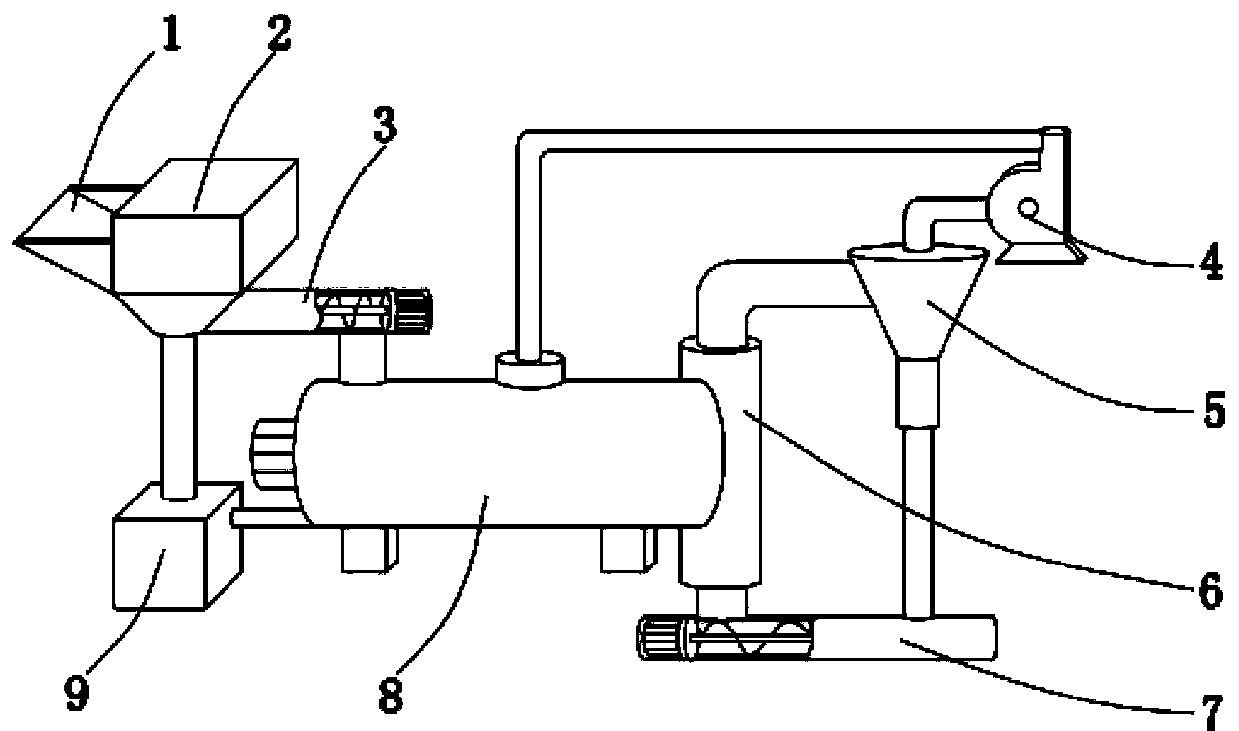

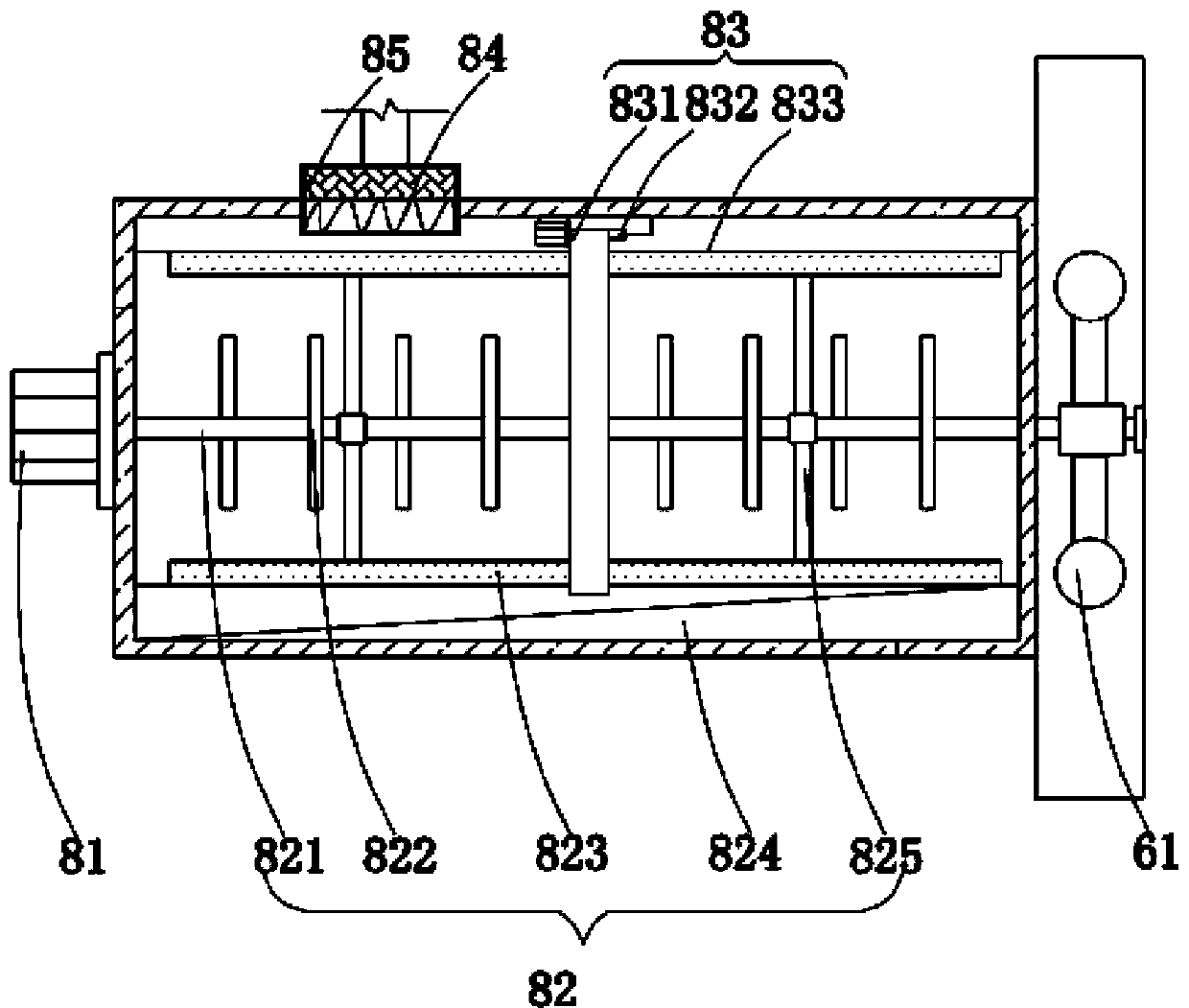

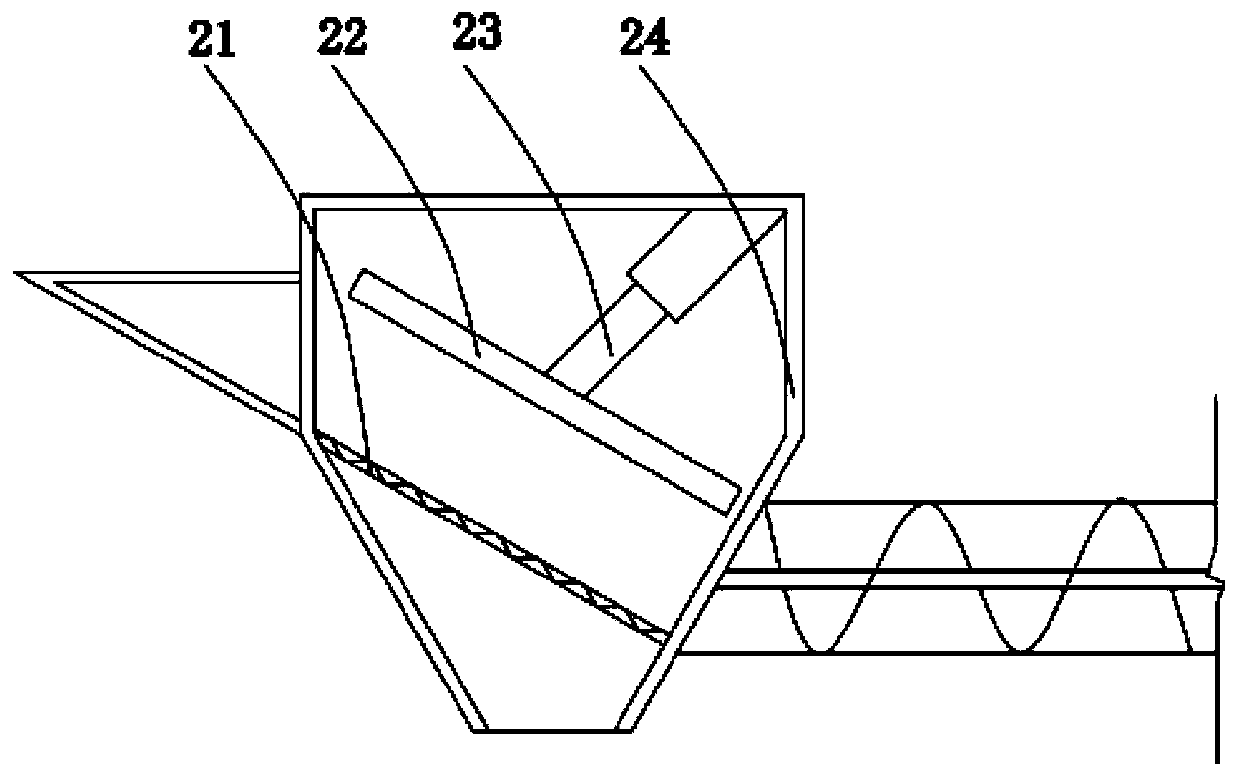

[0025] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 A schematic structural view of a preferred embodiment of the combined industrial sludge drying device provided by the present invention; Fig. figure 2 for figure 1 The schematic diagram of the internal structure of the box shell shown; image 3 for figure 1 The structural schematic diagram of the filter press mechanism shown; the combined industrial sludge drying device includes: a feed hopper 1; a filter press mechanism 2, the filter press mechanism 2 communicates with the feed hopper 1; a water storage tank 9, the storage The water tank 9 communicates with the filter press mechanism 2; the screw feed conveyor 3, the screw feed conveyor 3 communicates with the filter press mechanism 2; the box shell 8, the box shell 8 communicates with the screw feed Material co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com