Integral modular assembled partition wall

A prefabricated and integrated technology, applied in the direction of walls, sound insulation, insulation layers, etc., can solve the problems of difficult on-site coordination and management, low construction efficiency, inaccurate dimensions, etc., to achieve safe and civilized construction effects, less material and labor waste. , the effect of accurate base size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

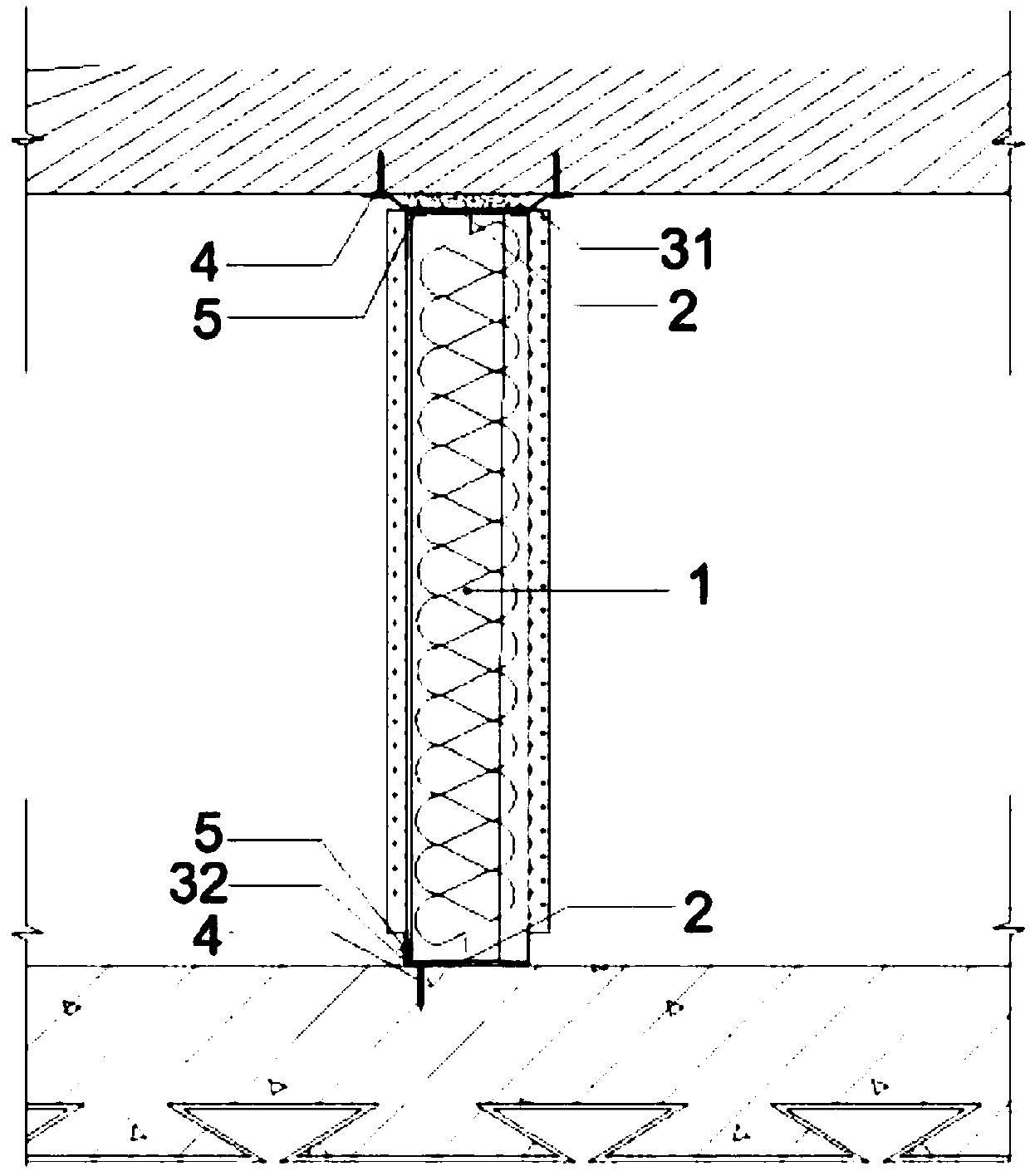

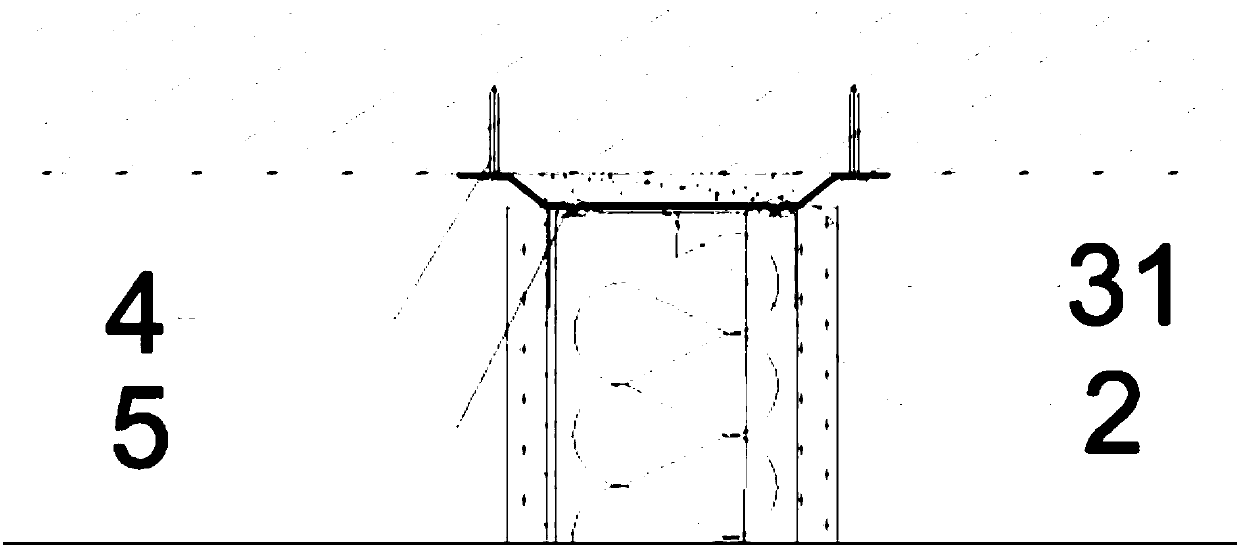

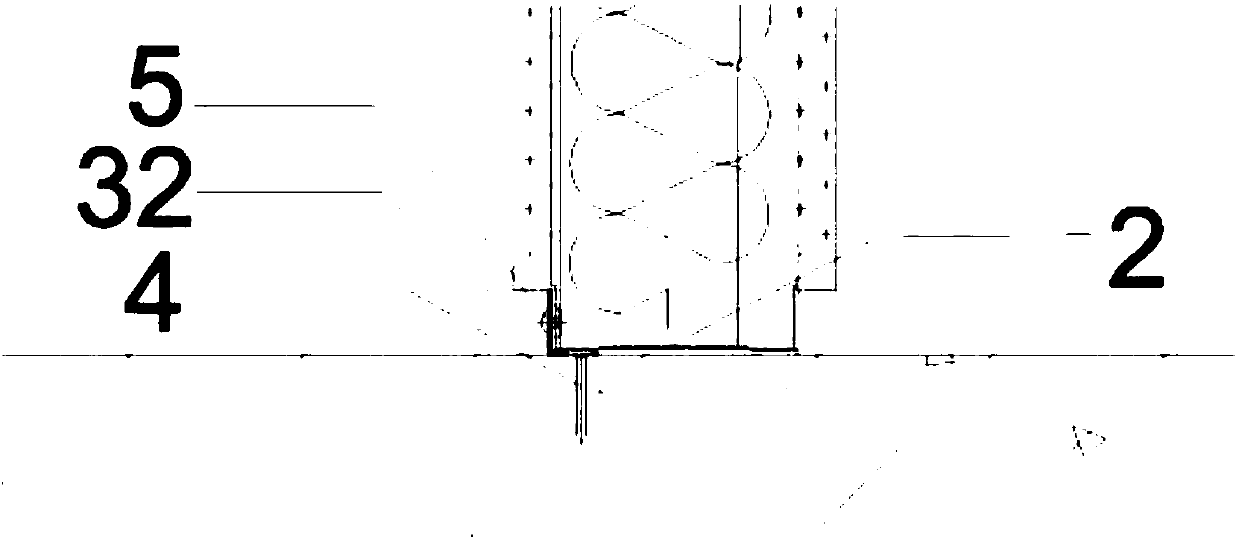

[0024] Such as Figure 1-3 Shown is a structural schematic diagram of the integral modular assembly type partition wall of the present invention. The overall modular assembled partition wall includes a main body of the modular partition wall 1, a sky and earth keel 2, a bendable metal strip 31, an L-shaped metal strip 32, steel nails 4 and rivets 5; the main body of the modular partition wall 1 is on both sides With heaven and earth keel 2. A bendable metal strip 31 is arranged at the sky and earth keel 2 on one side. The bendable metal strip 31 has a main body and a bendable portion extending from both sides of the main body. The main body and the sky and earth keel 2 are fixed by rivets 5, and the bendable portion is fixed to the top surface by steel nails 4 and can be bent. There is a fillable space between the metal strip 31 and the top surface. An L-shaped metal strip 32 is arranged at the sky and earth keel 2 on the other side. The L-shaped metal slat 32 has a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com