Pile body stress testing method for miniature steel pipe pile

A technology of stress testing and steel pipe piles, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problems of strength influence, test process influence, sensor string failure, etc., and achieve high survival rate, Strong anti-electromagnetic field interference ability and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

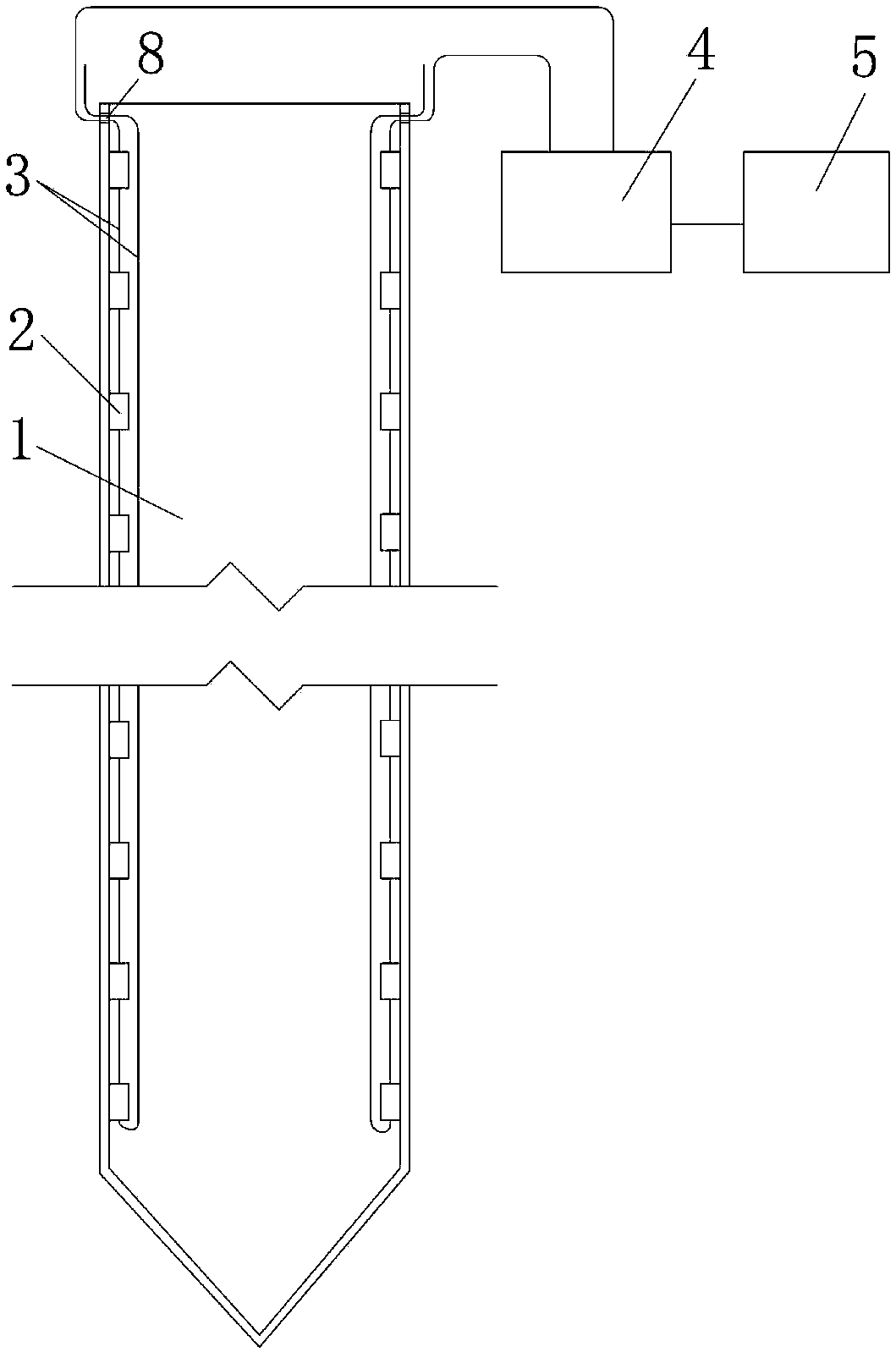

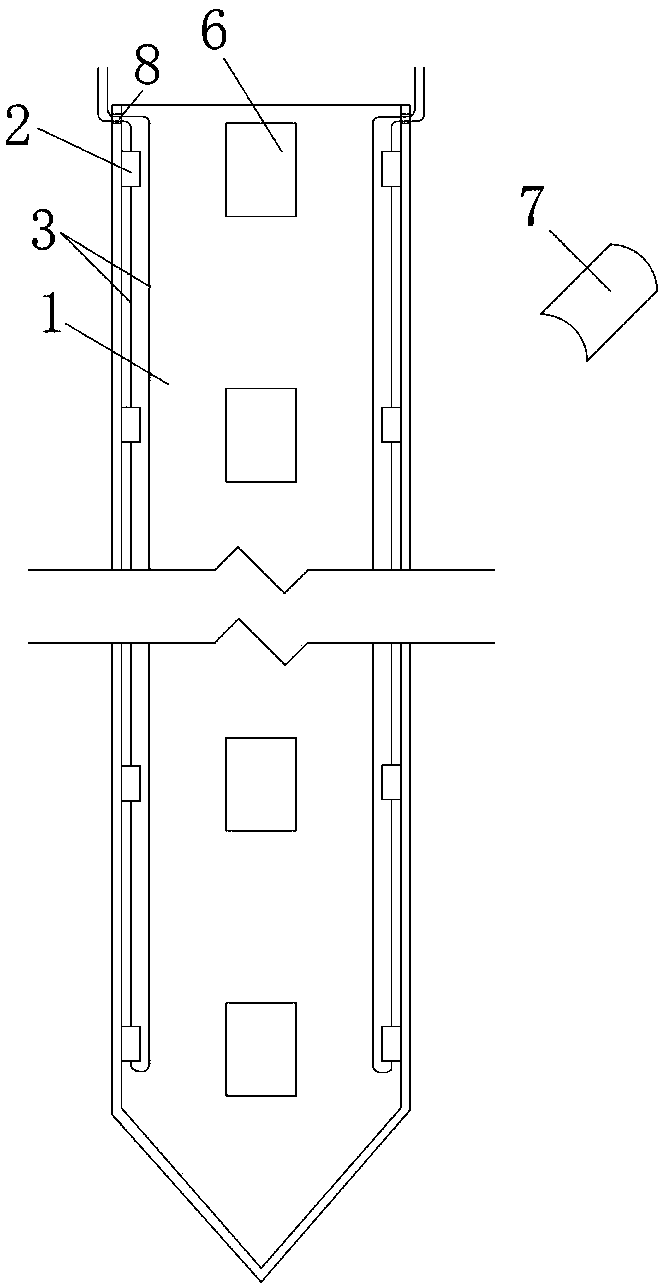

[0027] In this embodiment, the stress test of the pile body of the micro-steel pipe pile is used to complete the stress test, and the specific process is as follows:

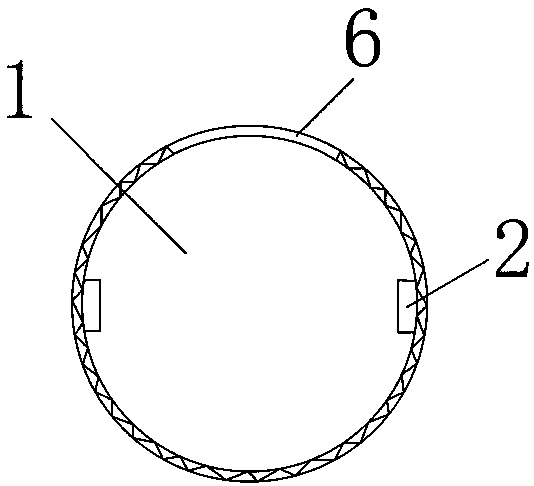

[0028] (1) According to the design requirements of the micro-steel pipe pile 1 to be tested, the distance between the sensors in the temperature self-compensating miniature fiber optic grating strain sensor string 2 is determined, and the temperature self-compensating miniature fiber optic grating strain sensors are connected in series to form a quasi-distributed The temperature self-compensating miniature optical fiber grating strain sensor string 2, the optical fiber between each temperature self-compensating miniature optical fiber grating strain sensor and the optical fiber leading out of the bottom surface are all protected by armored wire 3;

[0029] (2) Temperature self-compensating miniature optical fiber grating strain sensor series 2 is connected to the optical fiber grating sensor analyzer 4 and the da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com