Rotary knob speed regulation switch and automobile fan heater having the same

A speed-regulating switch and knob technology, which is applied in electric switches, vehicle parts, heating/cooling equipment, etc., can solve problems such as breakdown of copper sheets and plastic shells, electric sparks easily generated by current, and potential safety hazards, so as to improve the use of Performance and safety performance, increase mechanical life and service life, reduce the effect of motor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Below in conjunction with accompanying drawing this embodiment is described in detail:

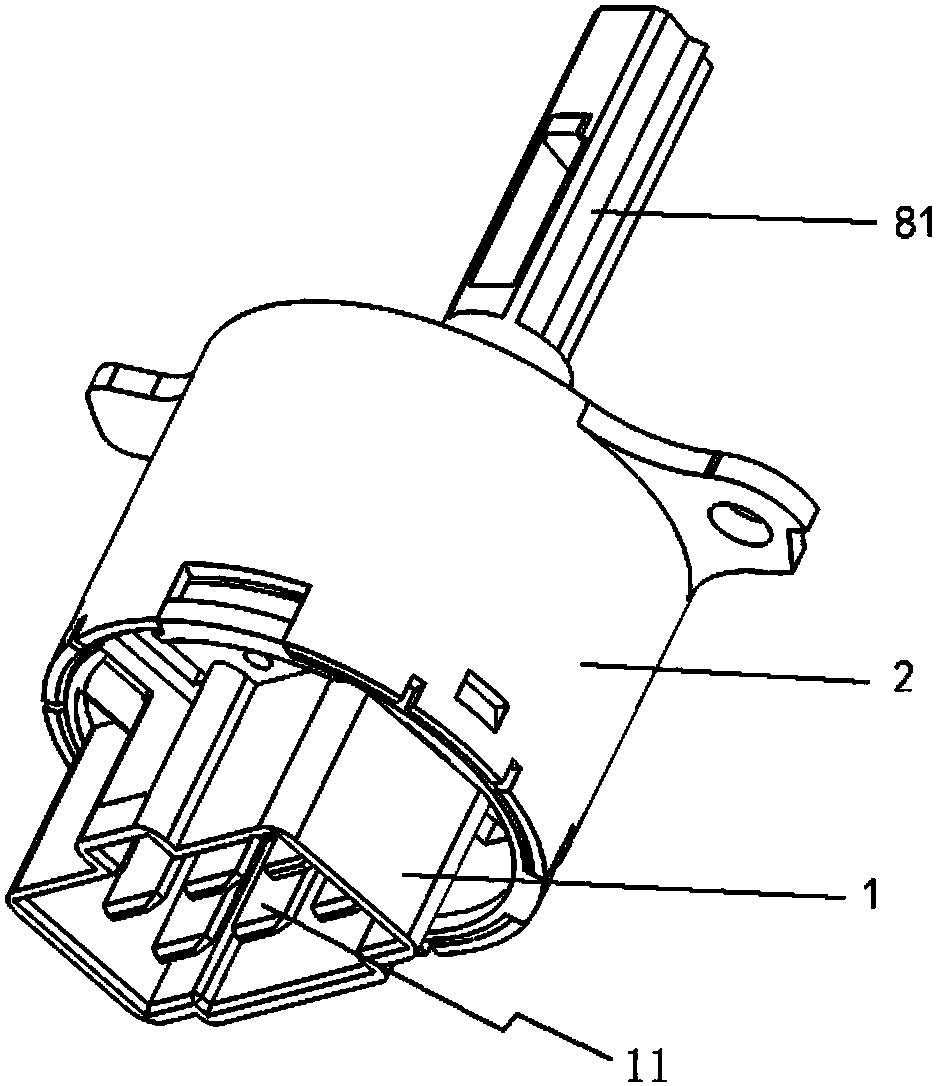

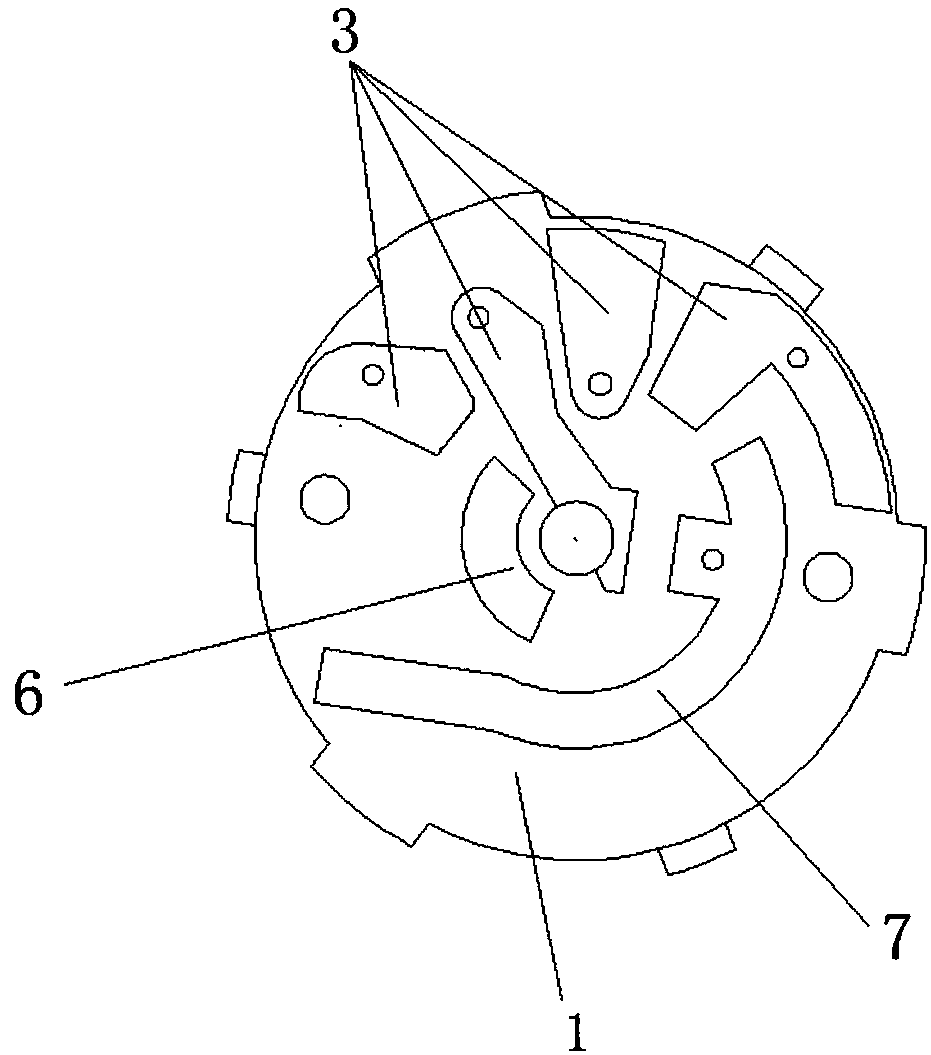

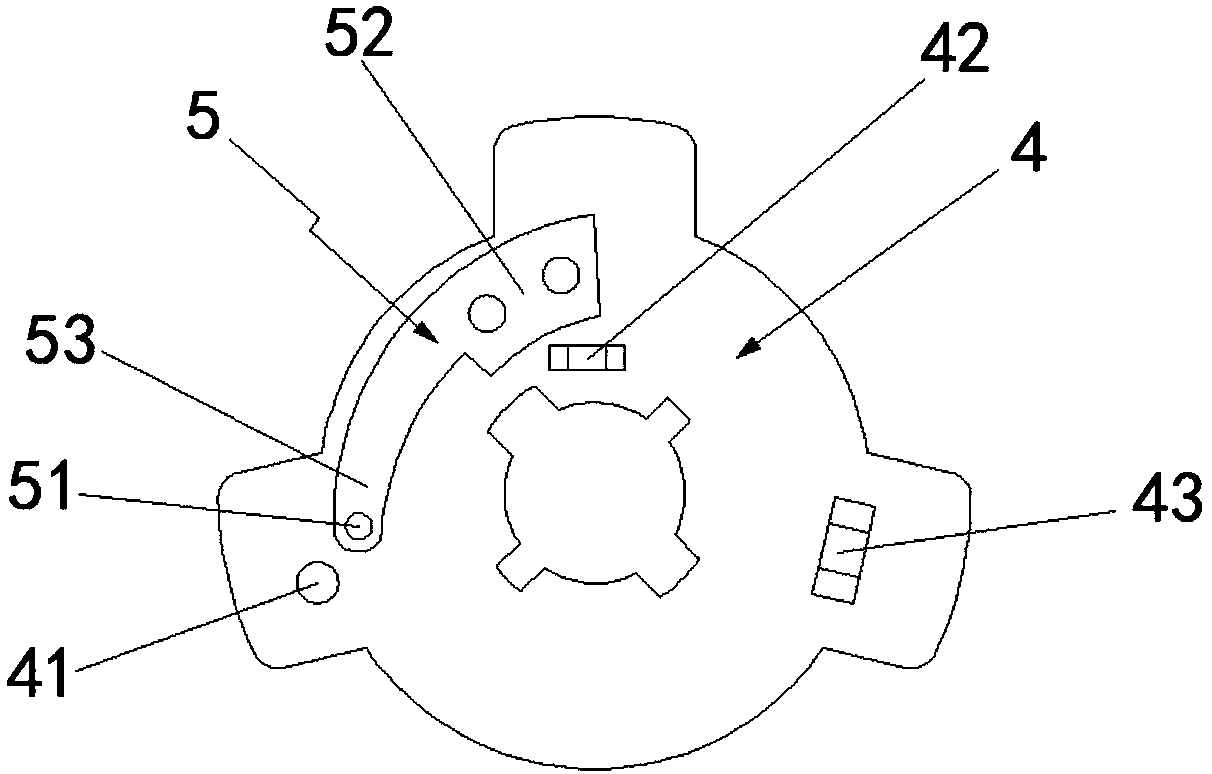

[0045] This embodiment provides as Figure 1-8 The rotary knob speed control switch shown includes several static contacts 3 arranged in an arc shape on the base 1 at intervals, a moving contact plate 4 arranged above the base 1 and driving the moving contact plate 4 The operating mechanism 8 that rotates so that the movable contact 41 on the movable contact plate 4 contacts with the plurality of static contact pieces 3 in sequence also includes:

[0046] The elastic contact piece 5 has a first end 52 fixed to the moving contact plate 4 and during the rotation of the moving contact plate 4, when the moving contact moves to the position between two adjacent static contact pieces 3 When there is a gap between them, the second end 53 always keeps in contact with any one of the two adjacent static contact pieces 3 .

[0047] The above-mentioned embodiment is the core technical solutio...

Embodiment 2

[0064] This embodiment provides a car heater switch, including the knob speed control switch described in Embodiment 1. Therefore, by turning the knob speed control switch to adjust the gear position, and then control the current size of the car heater, realize the adjustment of its air volume, easy to use, and improve the performance of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com