Circular antenna array design method for rotation circular polarization array element to produce OAM beam

A circular antenna and circularly polarized wave technology, applied in the field of wireless communication, can solve problems such as the complexity of the feeding network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

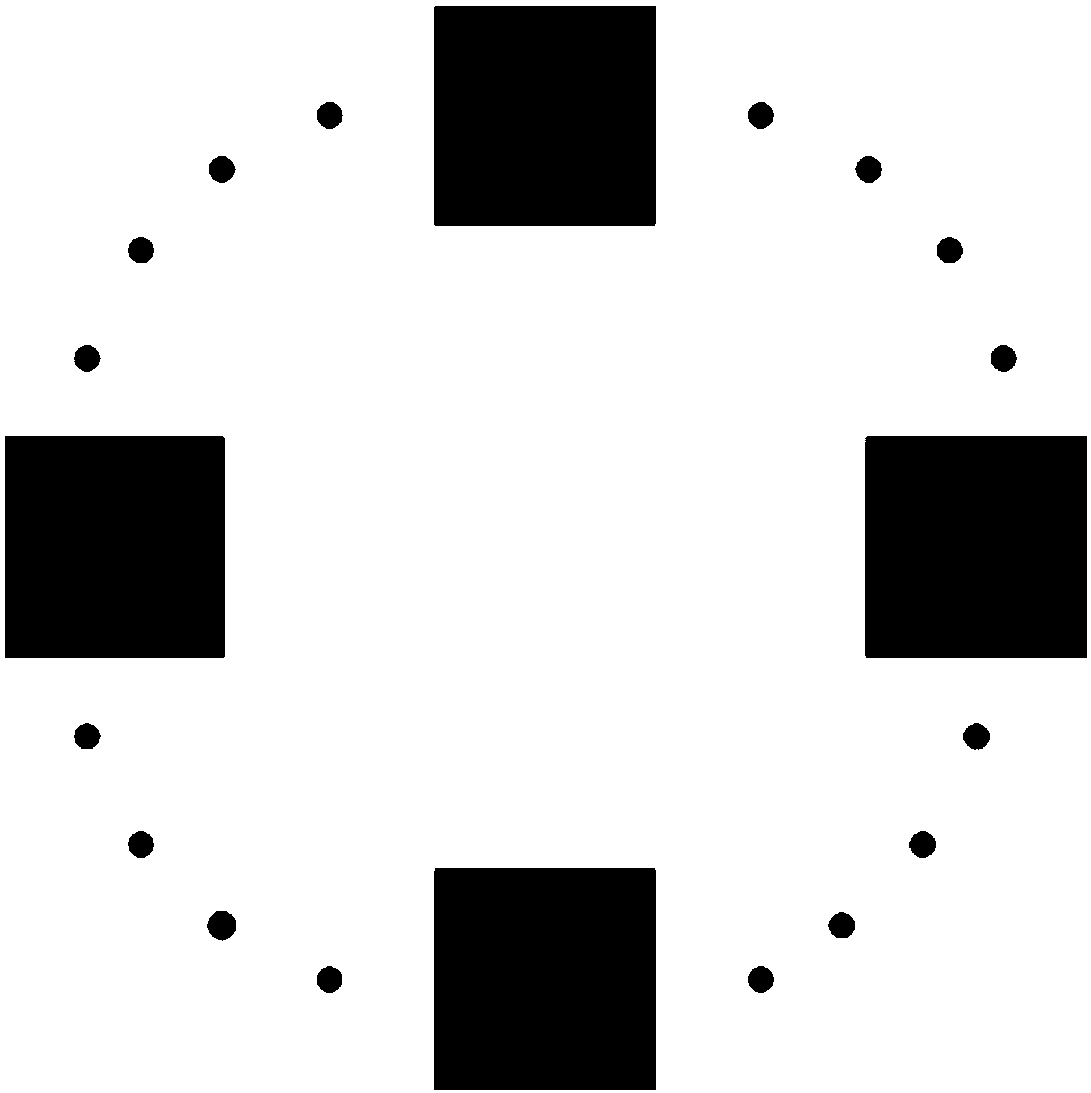

[0038] Using a circular array composed of 8 single-point fed circularly polarized microstrip antennas to rotate to generate OAM beams

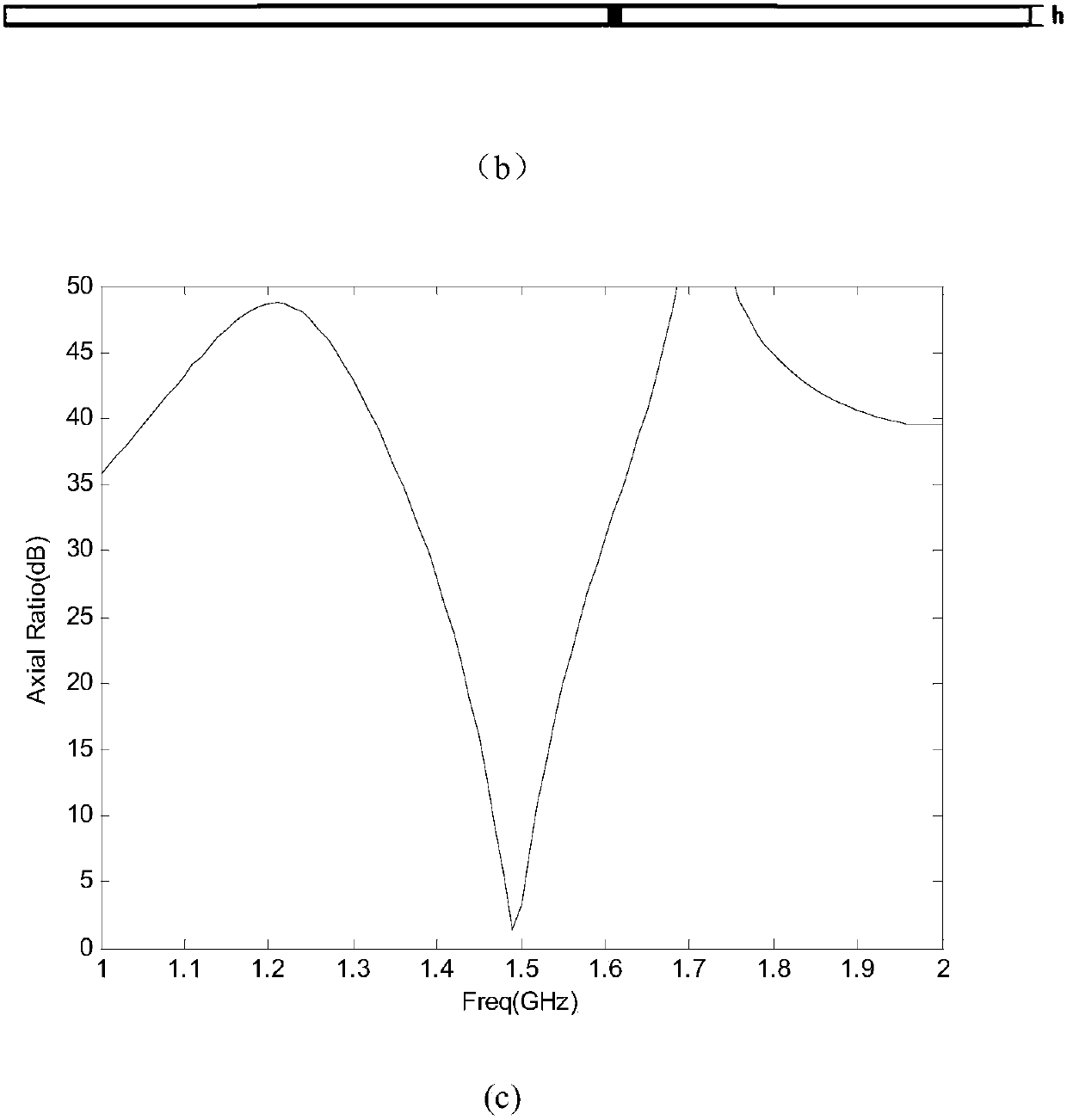

[0039] Step 1: Given the antenna center frequency f, determine and optimize the structure of a single array element to generate circularly polarized waves, so that the axial ratio of the circularly polarized waves at the center frequency is less than 3dB;

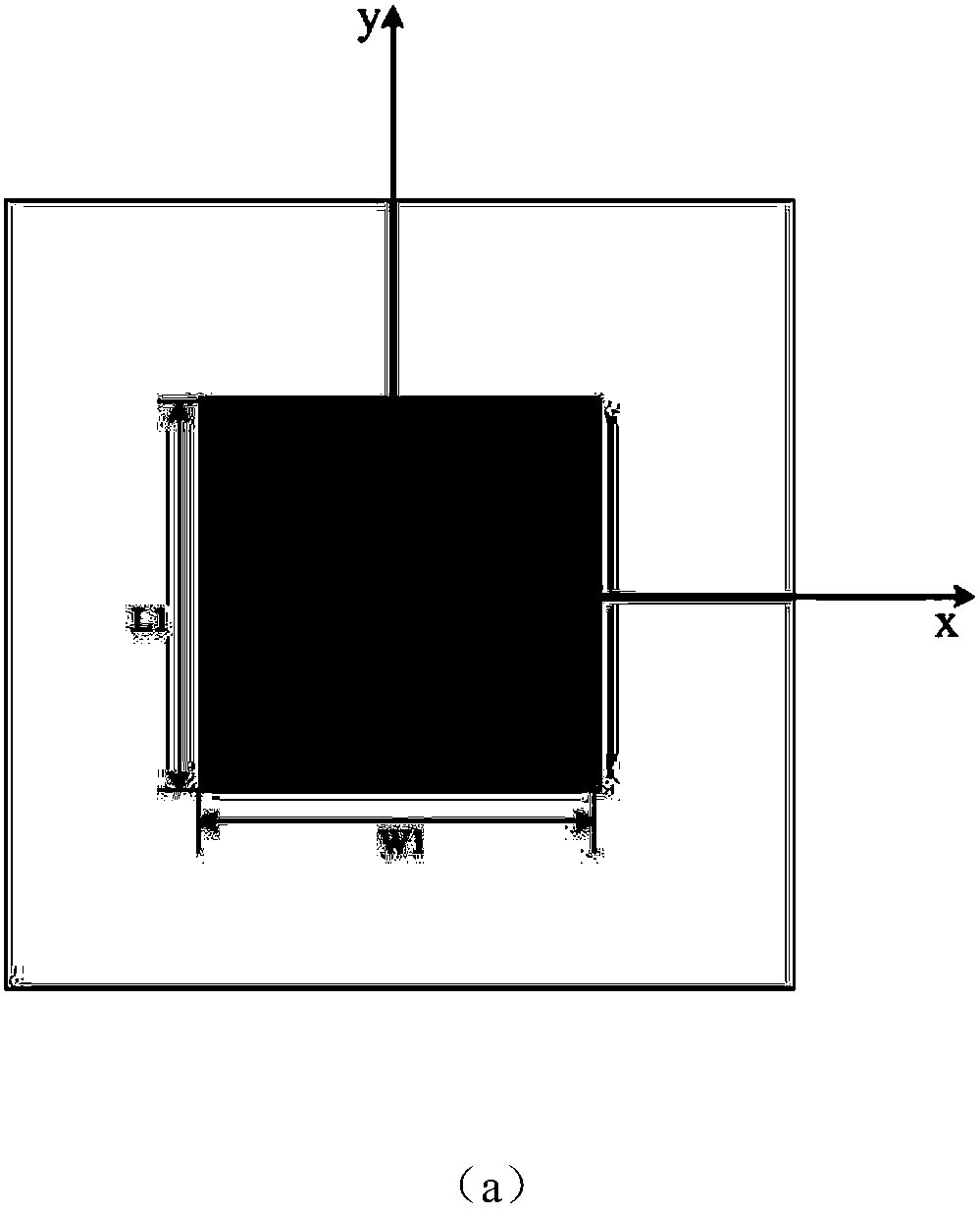

[0040] Let the antenna center frequency f be 1.5GHz, and the unit is set to generate right-handed circularly polarized waves. After calculation and simulation software optimization, the length of the rectangular radiation patch is L 1 =L 0 +a=47.31mm, width is W 1 =W 0 -a=45.98mm, where the initial dimension L 0 =W 0 =46.65mm, a=0.0143×L 0 . The material of the dielectric substrate is FR4 epoxy resin, and the height h=1.6mm. The distance between the feeding point and the x-axis and y-axis is d=8.85mm, and the radius of the coaxial feeder is 0.6mm. See the specific array element str...

Embodiment 2

[0049] OAM beams are generated by rotating a circular array composed of L-shaped probe orthogonal double-fed circularly polarized microstrip antennas

[0050] Step 1: Given the antenna center frequency f, determine and optimize the structure of a single array element to generate circularly polarized waves, so that the axial ratio of the circularly polarized waves at the center frequency is less than 3dB;

[0051] The antenna center frequency f is 2GHz. After calculation and simulation software optimization, the length and width of the square radiation patch are both taken as 46.65mm. The feeding point of the two L-shaped probes is directly below the midpoint of the two collar edges of the patch. The horizontal part points to the center of the patch, the vertical height is 13.8mm, the horizontal length is 17mm, the radius is 0.6mm, the material of the dielectric substrate is air, and the height is 20mm. See the specific structure Figure 4 (a)(b)(c), where, when the feeding me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Horizontal length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com